Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

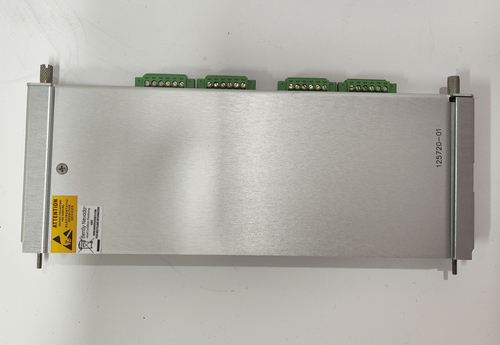

Bently Nevada 3500/25 128726-01 Key Phase External Terminal Module

Manufacturer:Bently Nevada

Product Number:3500/25 128726-01

Product Type:Key Phase External Terminal Module

Origin:USA

Dimensions:241.3 x 24.4 x 103.1 mm

Weight:0.46 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/25 128726-01 Key Phase External Terminal Module is a critical part of the Bently Nevada 3500 Series machinery protection system. Its main function is to provide a reliable interface for key phasor signals — essential in determining the phase angle of a rotating shaft. This information is vital for vector analysis, vibration diagnostics, and balancing applications in high-speed rotating machinery.

The 3500/25 module works in tandem with proximity probes and speed sensors to generate phase reference pulses. These signals are then used by other modules in the 3500 rack — such as vibration, speed, and transient data modules — to correlate vibration events with shaft rotation. This allows maintenance and reliability engineers to pinpoint issues like imbalance, misalignment, or looseness with much greater accuracy.

Built for long-term reliability and precision in critical applications, the 3500/25 is designed for industrial environments that demand high performance, including oil & gas, power generation, petrochemical, and manufacturing.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Key Phase External Terminal Module |

| Model Number | 3500/25 |

| Part Number | 128726-01 |

| System Compatibility | Bently Nevada 3500 Series Rack System |

| Function | Converts signal from Keyphasor transducers |

| Channels | 1 or 2 Keyphasor input channels |

| Signal Type | TTL compatible pulse input |

| Input Sources | Proximity probes or magnetic pickups |

| Pulse Width | 10 μs to 500 μs typical |

| Output Type | Digital signal to 3500 rack modules |

| Input Sensitivity | 3.5 V peak minimum for pulse detection |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Tolerance | 5%–95% non-condensing |

| Enclosure | External terminal block with shielded housing |

| Mounting Method | DIN rail or panel mountable |

| Power Requirements | Supplied via rack backplane |

| Dimensions (W x H x D) | 241.3 x 24.4 x 103.1 mm |

| Weight | 0.46 kg |

| Certifications | CE, UL, CSA, ATEX, RoHS |

| Material | Industrial-grade thermoplastic housing |

| Country of Origin | USA |

Applications

The 3500/25 Key Phase Module is a foundational component in machinery diagnostics and is used across a wide range of industrial sectors. Some typical applications include:

-

Turbomachinery Monitoring

Detects the precise angular position of the rotor for vibration phase referencing and unbalance diagnosis.

-

Provides input for advanced diagnostics such as orbit plots, Bode plots, and polar displays.

-

Rotor Balancing

Essential for field balancing operations by providing accurate phase reference pulses during operation.

-

Enables early detection of developing faults such as looseness, rubs, or shaft bow based on phase behavior.

-

Rotating Equipment in Power Plants

Used with steam turbines, gas turbines, and generators to monitor phase behavior in high-reliability environments.

-

Oil & Gas Processing Equipment

Helps in real-time monitoring of compressors, pumps, and motors where phase-triggered analysis is required.

Product Advantages

-

Accurate Phase Detection

Captures high-fidelity keyphasor signals necessary for vibration diagnostics and balancing.

-

Reliable Signal Conversion

Converts raw pulses from transducers into clean, usable signals for other modules in the 3500 rack.

-

Robust Design

Designed to operate in industrial settings with wide temperature and humidity tolerances.

-

High Compatibility

Seamlessly integrates with the entire 3500 Series monitoring system without needing additional configuration.

-

Noise Immunity

Shielded housing and internal filtering provide strong resistance to electrical noise.

-

Compact and Durable

Its small footprint makes it easy to mount in tight control panels while maintaining long-term durability.

-

Versatile Input Sources

Works with both proximity probes and magnetic pickups, allowing flexibility in field applications.

-

Maintenance-Free Operation

Once installed and wired, it requires no regular maintenance, offering peace of mind for critical operations.

Frequently Asked Questions (FAQ)

1. What does the 3500/25 Keyphasor Module actually do?

It receives input from a proximity or magnetic sensor and converts it into a precise digital pulse used for identifying the shaft position in rotating machinery.

2. Can this module support two Keyphasor signals?

Yes, it can be configured for single or dual input channels, depending on system requirements.

3. Is this module compatible with older Bently Nevada systems?

It is specifically designed for the 3500 Series but may be adapted in legacy upgrades with proper wiring and rack configurations.

4. What kind of sensors can be connected to this module?

It supports standard Bently Nevada proximity probes and magnetic pickups that provide TTL-type output pulses.

5. Does the 3500/25 store data or just transmit it?

It doesn’t store data — it conditions and transmits the signal to other processing modules in the rack.

6. Can the module operate in outdoor or harsh environments?

Yes, as long as it is installed in a protected control cabinet. It handles industrial temperatures and humidity levels well.

7. Do I need to configure the module with software?

No standalone configuration is needed. It works in conjunction with the rack and is configured as part of the system setup.

8. What is the purpose of a Keyphasor in machinery diagnostics?

Keyphasors allow engineers to synchronize vibration signals with shaft position for orbit, phase, and Bode plot analysis.

9. Is this module required for balancing operations?

Yes, balancing rotating machinery in the field typically requires a Keyphasor signal, which this module provides.

10. How is this module powered?

It draws power from the 3500 rack’s backplane, so no separate power supply is required.

Bently Nevada 3500/25 128726-01 Key Phase External Terminal Module

Manufacturer:Bently Nevada

Product Number:3500/25 128726-01

Product Type:Key Phase External Terminal Module

Origin:USA

Dimensions:241.3 x 24.4 x 103.1 mm

Weight:0.46 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/25 128726-01 Key Phase External Terminal Module is a critical part of the Bently Nevada 3500 Series machinery protection system. Its main function is to provide a reliable interface for key phasor signals — essential in determining the phase angle of a rotating shaft. This information is vital for vector analysis, vibration diagnostics, and balancing applications in high-speed rotating machinery.

The 3500/25 module works in tandem with proximity probes and speed sensors to generate phase reference pulses. These signals are then used by other modules in the 3500 rack — such as vibration, speed, and transient data modules — to correlate vibration events with shaft rotation. This allows maintenance and reliability engineers to pinpoint issues like imbalance, misalignment, or looseness with much greater accuracy.

Built for long-term reliability and precision in critical applications, the 3500/25 is designed for industrial environments that demand high performance, including oil & gas, power generation, petrochemical, and manufacturing.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Key Phase External Terminal Module |

| Model Number | 3500/25 |

| Part Number | 128726-01 |

| System Compatibility | Bently Nevada 3500 Series Rack System |

| Function | Converts signal from Keyphasor transducers |

| Channels | 1 or 2 Keyphasor input channels |

| Signal Type | TTL compatible pulse input |

| Input Sources | Proximity probes or magnetic pickups |

| Pulse Width | 10 μs to 500 μs typical |

| Output Type | Digital signal to 3500 rack modules |

| Input Sensitivity | 3.5 V peak minimum for pulse detection |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Tolerance | 5%–95% non-condensing |

| Enclosure | External terminal block with shielded housing |

| Mounting Method | DIN rail or panel mountable |

| Power Requirements | Supplied via rack backplane |

| Dimensions (W x H x D) | 241.3 x 24.4 x 103.1 mm |

| Weight | 0.46 kg |

| Certifications | CE, UL, CSA, ATEX, RoHS |

| Material | Industrial-grade thermoplastic housing |

| Country of Origin | USA |

Applications

The 3500/25 Key Phase Module is a foundational component in machinery diagnostics and is used across a wide range of industrial sectors. Some typical applications include:

-

Turbomachinery Monitoring

Detects the precise angular position of the rotor for vibration phase referencing and unbalance diagnosis.

-

Provides input for advanced diagnostics such as orbit plots, Bode plots, and polar displays.

-

Rotor Balancing

Essential for field balancing operations by providing accurate phase reference pulses during operation.

-

Enables early detection of developing faults such as looseness, rubs, or shaft bow based on phase behavior.

-

Rotating Equipment in Power Plants

Used with steam turbines, gas turbines, and generators to monitor phase behavior in high-reliability environments.

-

Oil & Gas Processing Equipment

Helps in real-time monitoring of compressors, pumps, and motors where phase-triggered analysis is required.

Product Advantages

-

Accurate Phase Detection

Captures high-fidelity keyphasor signals necessary for vibration diagnostics and balancing.

-

Reliable Signal Conversion

Converts raw pulses from transducers into clean, usable signals for other modules in the 3500 rack.

-

Robust Design

Designed to operate in industrial settings with wide temperature and humidity tolerances.

-

High Compatibility

Seamlessly integrates with the entire 3500 Series monitoring system without needing additional configuration.

-

Noise Immunity

Shielded housing and internal filtering provide strong resistance to electrical noise.

-

Compact and Durable

Its small footprint makes it easy to mount in tight control panels while maintaining long-term durability.

-

Versatile Input Sources

Works with both proximity probes and magnetic pickups, allowing flexibility in field applications.

-

Maintenance-Free Operation

Once installed and wired, it requires no regular maintenance, offering peace of mind for critical operations.

Frequently Asked Questions (FAQ)

1. What does the 3500/25 Keyphasor Module actually do?

It receives input from a proximity or magnetic sensor and converts it into a precise digital pulse used for identifying the shaft position in rotating machinery.

2. Can this module support two Keyphasor signals?

Yes, it can be configured for single or dual input channels, depending on system requirements.

3. Is this module compatible with older Bently Nevada systems?

It is specifically designed for the 3500 Series but may be adapted in legacy upgrades with proper wiring and rack configurations.

4. What kind of sensors can be connected to this module?

It supports standard Bently Nevada proximity probes and magnetic pickups that provide TTL-type output pulses.

5. Does the 3500/25 store data or just transmit it?

It doesn’t store data — it conditions and transmits the signal to other processing modules in the rack.

6. Can the module operate in outdoor or harsh environments?

Yes, as long as it is installed in a protected control cabinet. It handles industrial temperatures and humidity levels well.

7. Do I need to configure the module with software?

No standalone configuration is needed. It works in conjunction with the rack and is configured as part of the system setup.

8. What is the purpose of a Keyphasor in machinery diagnostics?

Keyphasors allow engineers to synchronize vibration signals with shaft position for orbit, phase, and Bode plot analysis.

9. Is this module required for balancing operations?

Yes, balancing rotating machinery in the field typically requires a Keyphasor signal, which this module provides.

10. How is this module powered?

It draws power from the 3500 rack’s backplane, so no separate power supply is required.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...