Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

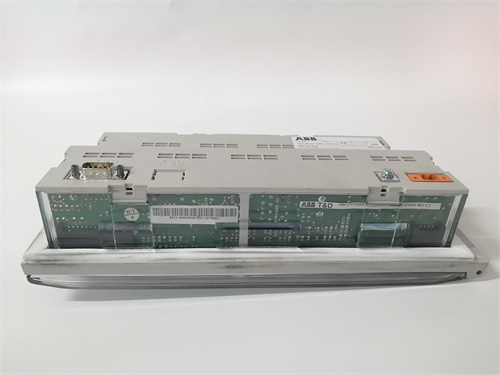

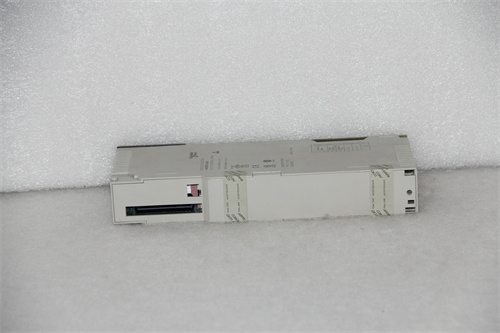

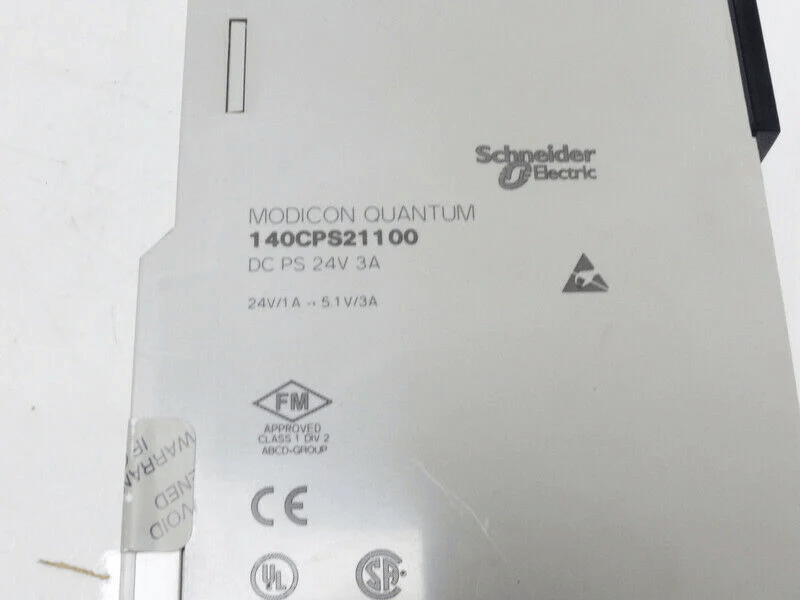

Schneider 140NOM21200C DIO Head-End Adaptor

Manufacturer:Schneider

Product Number:140NOM21200C

Product Type:DIO Head-End Adaptor

Origin:France

Dimensions:103.9 × 40.3 × 250 mm

Weight:0.493 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric 140NOM21200C is a dedicated Distributed I/O (DIO) Head-End Adaptor designed to interface with remote I/O modules in Modicon Quantum automation systems. This communication module enables seamless fieldbus integration and data exchange between a central processing unit (CPU) and distributed devices on a plant floor.

Built for high-performance industrial control systems, the 140NOM21200C manages real-time communication with distributed I/O blocks via Modbus Plus or Modbus RTU and offers hot-swapping capabilities and reliable diagnostics. It is commonly used in scenarios where scalability, modularity, and decentralized control are crucial for system optimization.

This module allows engineers to offload I/O processing, simplifying system expansion and improving the overall responsiveness of Quantum-based control architectures.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | DIO Head-End Adaptor Module |

| Model Number | 140NOM21200C |

| Manufacturer | Schneider Electric |

| Series | Modicon Quantum |

| Function | Distributed I/O communication head-end |

| Communication Protocol | Modbus, Modbus Plus |

| Interface Type | RS-485 |

| Baud Rate Support | Up to 1 Mbps |

| Connector Type | 9-pin D-sub (RS-232/RS-485) |

| LED Indicators | Communication status, power, error |

| Configuration Tool | Unity Pro / EcoStruxure Control Expert |

| Power Supply | Supplied via backplane |

| Power Consumption | Approx. 300 mA @ 5 VDC |

| Hot-Swap Support | Yes |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Mounting | Rack-mounted via Quantum chassis |

| Certifications | CE, UL, CSA, ATEX |

| Dimensions (H x W x D) | 103.9 × 40.3 × 250 mm |

| Weight | 0.493 kg |

Product Applications

The 140NOM21200C plays a crucial role in distributed automation networks, making it ideal for industries where centralized control must be extended to remote equipment without compromising performance. Key application areas include:

-

Water & Wastewater Treatment

Distributing control to field devices such as pumps, sensors, and valve actuators in large facilities.

-

Oil & Gas Facilities

Monitoring remote wellheads, compressor stations, and metering systems over serial communication protocols.

-

Factory Automation

Supporting flexible machine layouts by simplifying I/O distribution and wiring.

-

Food & Beverage Manufacturing

Enabling precise control of conveyor systems, batching operations, and packaging machines.

-

Transportation and Infrastructure

Used in intelligent transportation systems for distributed sensor integration and monitoring.

-

Power Plants

Assisting in generator control, switchyard monitoring, and SCADA integration.

Product Advantages

-

Reliable Communication Backbone

Ensures consistent and noise-immune data transfer between controllers and remote I/O devices.

-

Modular Scalability

Supports future system expansion by allowing additional remote I/O modules to be integrated easily.

-

Hot-Swappable Design

Enables replacement or upgrading of modules without system downtime—minimizing maintenance disruption.

-

Standardized Protocol Support

Compatible with widely used industrial protocols like Modbus and Modbus Plus, promoting interoperability.

-

Diagnostic Capability

Real-time status LEDs and detailed diagnostics via software ensure quick fault detection and troubleshooting.

-

Compact Footprint

Small form factor makes it suitable for space-constrained control cabinets.

-

Backplane-Powered

Eliminates the need for external wiring or power sources, simplifying installation.

Frequently Asked Questions (FAQ)

1. What is the primary role of the 140NOM21200C module?

It acts as a communication bridge between the Quantum CPU and distributed I/O modules using Modbus or Modbus Plus protocols.

2. Can this module be used for remote I/O over Modbus RTU?

Yes, it supports Modbus RTU communication over RS-485, allowing integration with third-party Modbus devices.

3. Is it compatible with hot swapping?

Yes, the module can be inserted or removed from a powered rack without interrupting system operation.

4. Which software do I need to configure the module?

Unity Pro or EcoStruxure Control Expert are used for module configuration and diagnostics.

5. Can the 140NOM21200C be used in hazardous environments?

Yes, it carries ATEX, UL, and CSA certifications, making it suitable for industrial use in regulated zones.

6. How is the module powered?

It draws power directly from the Quantum backplane—no external power supply is required.

7. How many remote I/O drops can it manage?

This depends on the Quantum system configuration, but typically up to 31 Modbus slave devices are supported on RS-485.

8. What indicators are available on the front panel?

LEDs for Power, Communication (TX/RX), and Error provide immediate visual diagnostics.

9. Is it compatible with all Modicon Quantum CPUs?

Yes, it’s designed to be used with Quantum systems and is fully compatible across the platform.

10. What type of connectors does the module use?

It typically features a 9-pin D-sub connector for RS-232/485 communication, depending on the application.

Schneider 140NOM21200C DIO Head-End Adaptor

Manufacturer:Schneider

Product Number:140NOM21200C

Product Type:DIO Head-End Adaptor

Origin:France

Dimensions:103.9 × 40.3 × 250 mm

Weight:0.493 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric 140NOM21200C is a dedicated Distributed I/O (DIO) Head-End Adaptor designed to interface with remote I/O modules in Modicon Quantum automation systems. This communication module enables seamless fieldbus integration and data exchange between a central processing unit (CPU) and distributed devices on a plant floor.

Built for high-performance industrial control systems, the 140NOM21200C manages real-time communication with distributed I/O blocks via Modbus Plus or Modbus RTU and offers hot-swapping capabilities and reliable diagnostics. It is commonly used in scenarios where scalability, modularity, and decentralized control are crucial for system optimization.

This module allows engineers to offload I/O processing, simplifying system expansion and improving the overall responsiveness of Quantum-based control architectures.

Product Specifications

| Parameter | Details |

|---|---|

| Product Name | DIO Head-End Adaptor Module |

| Model Number | 140NOM21200C |

| Manufacturer | Schneider Electric |

| Series | Modicon Quantum |

| Function | Distributed I/O communication head-end |

| Communication Protocol | Modbus, Modbus Plus |

| Interface Type | RS-485 |

| Baud Rate Support | Up to 1 Mbps |

| Connector Type | 9-pin D-sub (RS-232/RS-485) |

| LED Indicators | Communication status, power, error |

| Configuration Tool | Unity Pro / EcoStruxure Control Expert |

| Power Supply | Supplied via backplane |

| Power Consumption | Approx. 300 mA @ 5 VDC |

| Hot-Swap Support | Yes |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Mounting | Rack-mounted via Quantum chassis |

| Certifications | CE, UL, CSA, ATEX |

| Dimensions (H x W x D) | 103.9 × 40.3 × 250 mm |

| Weight | 0.493 kg |

Product Applications

The 140NOM21200C plays a crucial role in distributed automation networks, making it ideal for industries where centralized control must be extended to remote equipment without compromising performance. Key application areas include:

-

Water & Wastewater Treatment

Distributing control to field devices such as pumps, sensors, and valve actuators in large facilities.

-

Oil & Gas Facilities

Monitoring remote wellheads, compressor stations, and metering systems over serial communication protocols.

-

Factory Automation

Supporting flexible machine layouts by simplifying I/O distribution and wiring.

-

Food & Beverage Manufacturing

Enabling precise control of conveyor systems, batching operations, and packaging machines.

-

Transportation and Infrastructure

Used in intelligent transportation systems for distributed sensor integration and monitoring.

-

Power Plants

Assisting in generator control, switchyard monitoring, and SCADA integration.

Product Advantages

-

Reliable Communication Backbone

Ensures consistent and noise-immune data transfer between controllers and remote I/O devices.

-

Modular Scalability

Supports future system expansion by allowing additional remote I/O modules to be integrated easily.

-

Hot-Swappable Design

Enables replacement or upgrading of modules without system downtime—minimizing maintenance disruption.

-

Standardized Protocol Support

Compatible with widely used industrial protocols like Modbus and Modbus Plus, promoting interoperability.

-

Diagnostic Capability

Real-time status LEDs and detailed diagnostics via software ensure quick fault detection and troubleshooting.

-

Compact Footprint

Small form factor makes it suitable for space-constrained control cabinets.

-

Backplane-Powered

Eliminates the need for external wiring or power sources, simplifying installation.

Frequently Asked Questions (FAQ)

1. What is the primary role of the 140NOM21200C module?

It acts as a communication bridge between the Quantum CPU and distributed I/O modules using Modbus or Modbus Plus protocols.

2. Can this module be used for remote I/O over Modbus RTU?

Yes, it supports Modbus RTU communication over RS-485, allowing integration with third-party Modbus devices.

3. Is it compatible with hot swapping?

Yes, the module can be inserted or removed from a powered rack without interrupting system operation.

4. Which software do I need to configure the module?

Unity Pro or EcoStruxure Control Expert are used for module configuration and diagnostics.

5. Can the 140NOM21200C be used in hazardous environments?

Yes, it carries ATEX, UL, and CSA certifications, making it suitable for industrial use in regulated zones.

6. How is the module powered?

It draws power directly from the Quantum backplane—no external power supply is required.

7. How many remote I/O drops can it manage?

This depends on the Quantum system configuration, but typically up to 31 Modbus slave devices are supported on RS-485.

8. What indicators are available on the front panel?

LEDs for Power, Communication (TX/RX), and Error provide immediate visual diagnostics.

9. Is it compatible with all Modicon Quantum CPUs?

Yes, it’s designed to be used with Quantum systems and is fully compatible across the platform.

10. What type of connectors does the module use?

It typically features a 9-pin D-sub connector for RS-232/485 communication, depending on the application.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...