Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

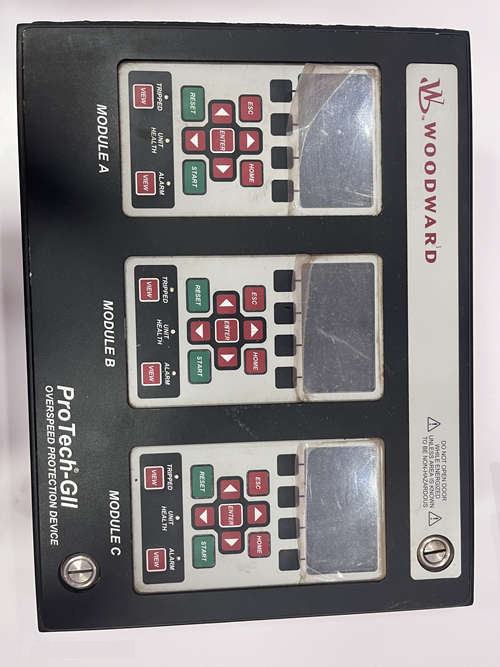

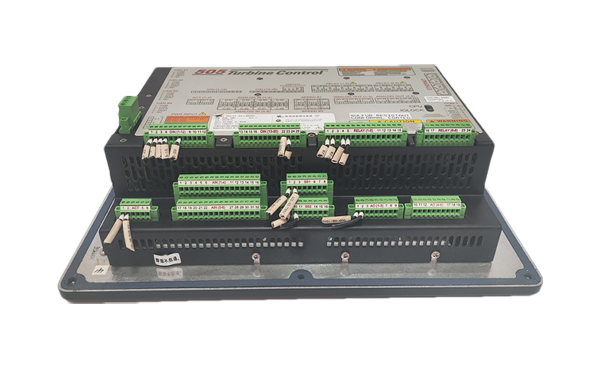

Woodward 8200-1312 Digital Governor Turbine Control

Manufacturer:Woodward

Product Number:8200-1312

Product Type:Digital Governor Turbine Control

Origin:USA

Dimensions:350 × 200 × 100 mm

Weight:2.5 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 8200-1312 is a high-performance Digital Governor Turbine Control system specifically engineered for demanding turbine control applications. It integrates advanced control algorithms, precise speed and load management, and robust diagnostics, making it a reliable solution for industrial turbines in power generation, mechanical drive, and marine propulsion sectors.

With a focus on accuracy, real-time responsiveness, and flexible configuration, the 8200-1312 is widely used to improve operational efficiency and safety. Designed by Woodward, a global leader in energy control systems, this digital governor offers unparalleled control functionality for steam, gas, and hydro turbine applications.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | Woodward 8200-1312 |

| Control Type | Digital Governor Turbine Control |

| Processor | High-speed microprocessor with redundancy support |

| Input Voltage | 18 to 32 VDC |

| Power Consumption | < 35 W typical |

| Operating Temperature Range | –40 °C to +70 °C |

| Humidity Range | 5% to 95% non-condensing |

| Analog Inputs | 4–20 mA, ±10 V |

| Digital Inputs | Discrete (dry contact or TTL level) |

| Communication Interfaces | CAN, RS-232, RS-485, Ethernet |

| Mounting Type | Panel-mounted |

| Dimensions (W x H x D) | 350 × 200 × 100 mm |

| Weight | 2.5 kg |

| Protection Class | IP20 (standard), optional conformal coating |

| Certifications | CE, UL, CSA, ATEX (depending on config) |

Applications

The Woodward 8200-1312 is versatile and suitable for a wide range of industrial and commercial turbine control applications, including:

-

Steam Turbines in power plants, refineries, and paper mills

-

Gas Turbines used in mechanical drive and power generation

-

Hydro Turbines in water-based renewable energy facilities

-

Marine Propulsion Systems where precise control is critical

-

Compressor Control Systems in oil and gas facilities

-

Industrial Engines in combined heat and power (CHP) setups

Key Advantages

-

High-Speed Processing: Allows real-time control and ultra-fast response to transient conditions.

-

Flexible Configuration: Easily integrates with different turbine types through customizable I/O and logic functions.

-

Rugged Design: Operates reliably in harsh industrial environments with high vibration and temperature fluctuations.

-

Advanced Diagnostics: Supports proactive maintenance via internal event logging and fault detection.

-

Secure Communication: Multiple protocols ensure secure and redundant communication with DCS/SCADA systems.

-

Modular Architecture: Scalable platform for adding features like fuel scheduling, overspeed protection, and load sharing.

-

Global Standards Compliance: Meets strict international safety and performance certifications, allowing global deployment.

Frequently Asked Questions (FAQ)

-

What types of turbines are compatible with the 8200-1312?

It supports steam, gas, and hydro turbines with both mechanical and electronic actuation systems.

-

Is remote monitoring supported?

Yes, it offers Ethernet, CAN, and serial communication ports for remote monitoring and diagnostics.

-

Can this controller be integrated with SCADA systems?

Absolutely. It supports Modbus and other protocols for seamless SCADA or DCS integration.

-

Does the system support redundant configuration?

Yes, dual-redundant configurations can be set up to enhance reliability in critical operations.

-

What is the average MTBF (Mean Time Between Failures)?

The 8200-1312 has a high MTBF exceeding 100,000 hours, depending on the application environment.

-

How is the software configured?

Configuration is done using Woodward’s engineering tools like GAP or ToolKit software.

-

Are firmware updates available?

Yes, firmware updates are released periodically and can be installed via secured channels.

-

Does it support automatic load sharing?

Yes, it includes built-in features for isochronous and droop load sharing between multiple units.

-

Can it be used in explosive environments?

With the proper ATEX-certified configuration and enclosures, it can be used in hazardous areas.

-

What is the expected service life of the controller?

With regular maintenance, the expected service life is over 15 years.

Woodward 8200-1312 Digital Governor Turbine Control

Manufacturer:Woodward

Product Number:8200-1312

Product Type:Digital Governor Turbine Control

Origin:USA

Dimensions:350 × 200 × 100 mm

Weight:2.5 kg

Views:38

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 8200-1312 is a high-performance Digital Governor Turbine Control system specifically engineered for demanding turbine control applications. It integrates advanced control algorithms, precise speed and load management, and robust diagnostics, making it a reliable solution for industrial turbines in power generation, mechanical drive, and marine propulsion sectors.

With a focus on accuracy, real-time responsiveness, and flexible configuration, the 8200-1312 is widely used to improve operational efficiency and safety. Designed by Woodward, a global leader in energy control systems, this digital governor offers unparalleled control functionality for steam, gas, and hydro turbine applications.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | Woodward 8200-1312 |

| Control Type | Digital Governor Turbine Control |

| Processor | High-speed microprocessor with redundancy support |

| Input Voltage | 18 to 32 VDC |

| Power Consumption | < 35 W typical |

| Operating Temperature Range | –40 °C to +70 °C |

| Humidity Range | 5% to 95% non-condensing |

| Analog Inputs | 4–20 mA, ±10 V |

| Digital Inputs | Discrete (dry contact or TTL level) |

| Communication Interfaces | CAN, RS-232, RS-485, Ethernet |

| Mounting Type | Panel-mounted |

| Dimensions (W x H x D) | 350 × 200 × 100 mm |

| Weight | 2.5 kg |

| Protection Class | IP20 (standard), optional conformal coating |

| Certifications | CE, UL, CSA, ATEX (depending on config) |

Applications

The Woodward 8200-1312 is versatile and suitable for a wide range of industrial and commercial turbine control applications, including:

-

Steam Turbines in power plants, refineries, and paper mills

-

Gas Turbines used in mechanical drive and power generation

-

Hydro Turbines in water-based renewable energy facilities

-

Marine Propulsion Systems where precise control is critical

-

Compressor Control Systems in oil and gas facilities

-

Industrial Engines in combined heat and power (CHP) setups

Key Advantages

-

High-Speed Processing: Allows real-time control and ultra-fast response to transient conditions.

-

Flexible Configuration: Easily integrates with different turbine types through customizable I/O and logic functions.

-

Rugged Design: Operates reliably in harsh industrial environments with high vibration and temperature fluctuations.

-

Advanced Diagnostics: Supports proactive maintenance via internal event logging and fault detection.

-

Secure Communication: Multiple protocols ensure secure and redundant communication with DCS/SCADA systems.

-

Modular Architecture: Scalable platform for adding features like fuel scheduling, overspeed protection, and load sharing.

-

Global Standards Compliance: Meets strict international safety and performance certifications, allowing global deployment.

Frequently Asked Questions (FAQ)

-

What types of turbines are compatible with the 8200-1312?

It supports steam, gas, and hydro turbines with both mechanical and electronic actuation systems.

-

Is remote monitoring supported?

Yes, it offers Ethernet, CAN, and serial communication ports for remote monitoring and diagnostics.

-

Can this controller be integrated with SCADA systems?

Absolutely. It supports Modbus and other protocols for seamless SCADA or DCS integration.

-

Does the system support redundant configuration?

Yes, dual-redundant configurations can be set up to enhance reliability in critical operations.

-

What is the average MTBF (Mean Time Between Failures)?

The 8200-1312 has a high MTBF exceeding 100,000 hours, depending on the application environment.

-

How is the software configured?

Configuration is done using Woodward’s engineering tools like GAP or ToolKit software.

-

Are firmware updates available?

Yes, firmware updates are released periodically and can be installed via secured channels.

-

Does it support automatic load sharing?

Yes, it includes built-in features for isochronous and droop load sharing between multiple units.

-

Can it be used in explosive environments?

With the proper ATEX-certified configuration and enclosures, it can be used in hazardous areas.

-

What is the expected service life of the controller?

With regular maintenance, the expected service life is over 15 years.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...