Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

GE Fanuc IS200TVIBH2BBB Specialized Module

Manufacturer:General Electric

Part Number:IS200TVIBH2BBB

Product Type:Specialized Module

Series:GE Speedtronic Mark V

Stock:IN STOCK

Repair:3-7 Day

Rush Repair:24-48 Hrs.

Warranty:3 Years

Dimensions:72 x 36 x 85 mm (2.83 x 1.42 x 3.35 in)

Weight:0.35 kg (0.77 lbs)

Product Description

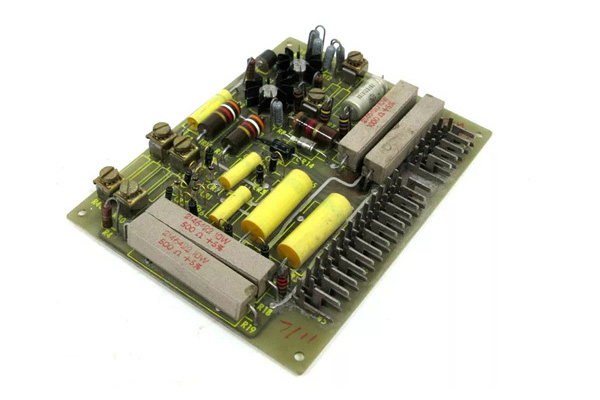

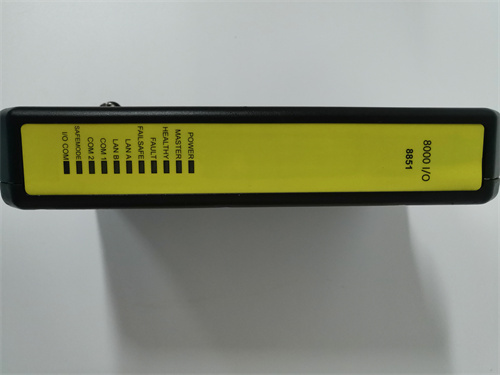

The GE Fanuc IS200TVIBH2BBB is a specialized module used in the Speedtronic Mark VI turbine control system. This system manages the operations of industrial steam and gas turbines, both small and large.

Key Functions

- Vibration Termination: The IS200TVIBH2BBB acts as a Vibration Termination board. It controls and contains vibration data within the turbine system.

- Data Processing: The module processes and manages vibration data using integrated circuits.

- Signal Conditioning: It conditions signals to ensure data accuracy and reliability for other control system components.

Construction and Features

- Integrated Circuits: Various integrated circuits on the module provide its core functionality.

- Passive Components: It includes resistors and capacitors for additional functionality.

- Connectors: Fourteen plug connectors are placed on one side for interfacing with system components.

- Terminal Blocks: Two large terminal blocks on one edge offer screw connections for secure wiring.

Applications

- Turbine Control: The IS200TVIBH2BBB is essential for the Speedtronic Mark VI system, focusing on turbine control.

- Vibration Monitoring: It monitors and controls vibrations, ensuring optimal turbine performance and preventing damage.

Benefits

- Reliability: Built to withstand harsh industrial conditions, the module offers dependable performance.

- Compatibility: It integrates seamlessly into the Speedtronic Mark VI system for a cohesive control solution.

- Data Accuracy: Signal conditioning ensures the accuracy and trustworthiness of the provided data.

GE Fanuc IS200TVIBH2BBB Specialized Module

Manufacturer:General Electric

Part Number:IS200TVIBH2BBB

Product Type:Specialized Module

Series:GE Speedtronic Mark V

Stock:IN STOCK

Repair:3-7 Day

Rush Repair:24-48 Hrs.

Warranty:3 Years

Dimensions:72 x 36 x 85 mm (2.83 x 1.42 x 3.35 in)

Weight:0.35 kg (0.77 lbs)

Product Description

The GE Fanuc IS200TVIBH2BBB is a specialized module used in the Speedtronic Mark VI turbine control system. This system manages the operations of industrial steam and gas turbines, both small and large.

Key Functions

- Vibration Termination: The IS200TVIBH2BBB acts as a Vibration Termination board. It controls and contains vibration data within the turbine system.

- Data Processing: The module processes and manages vibration data using integrated circuits.

- Signal Conditioning: It conditions signals to ensure data accuracy and reliability for other control system components.

Construction and Features

- Integrated Circuits: Various integrated circuits on the module provide its core functionality.

- Passive Components: It includes resistors and capacitors for additional functionality.

- Connectors: Fourteen plug connectors are placed on one side for interfacing with system components.

- Terminal Blocks: Two large terminal blocks on one edge offer screw connections for secure wiring.

Applications

- Turbine Control: The IS200TVIBH2BBB is essential for the Speedtronic Mark VI system, focusing on turbine control.

- Vibration Monitoring: It monitors and controls vibrations, ensuring optimal turbine performance and preventing damage.

Benefits

- Reliability: Built to withstand harsh industrial conditions, the module offers dependable performance.

- Compatibility: It integrates seamlessly into the Speedtronic Mark VI system for a cohesive control solution.

- Data Accuracy: Signal conditioning ensures the accuracy and trustworthiness of the provided data.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...