Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

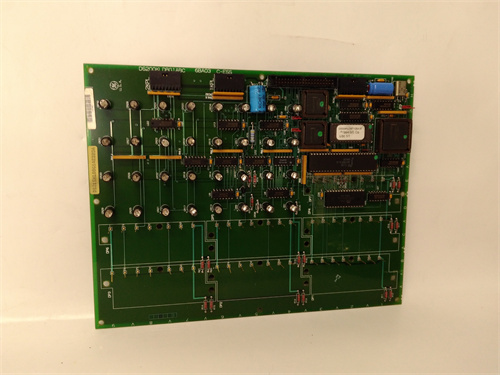

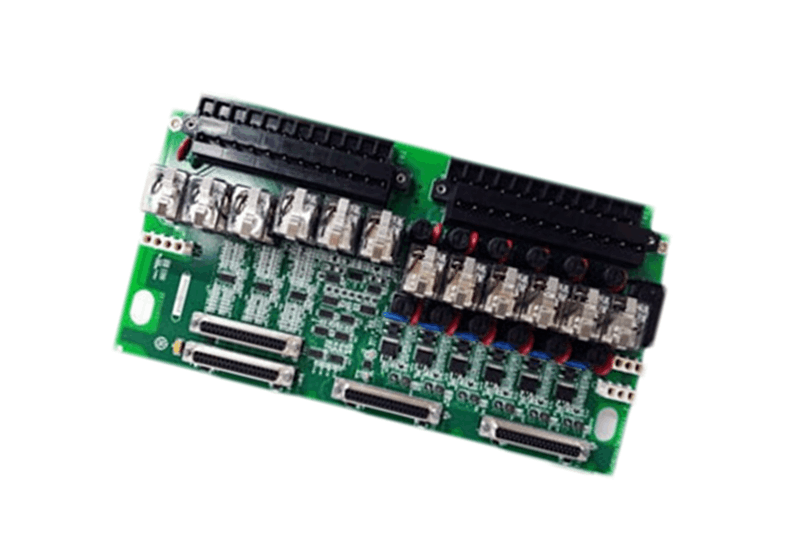

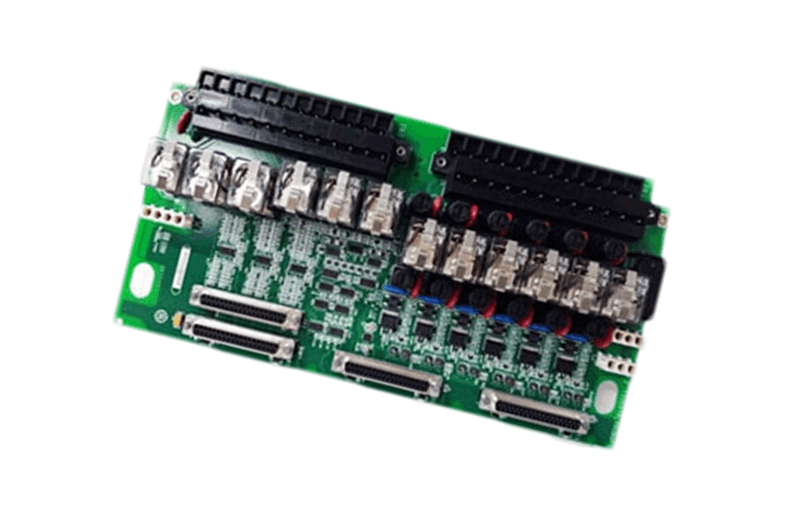

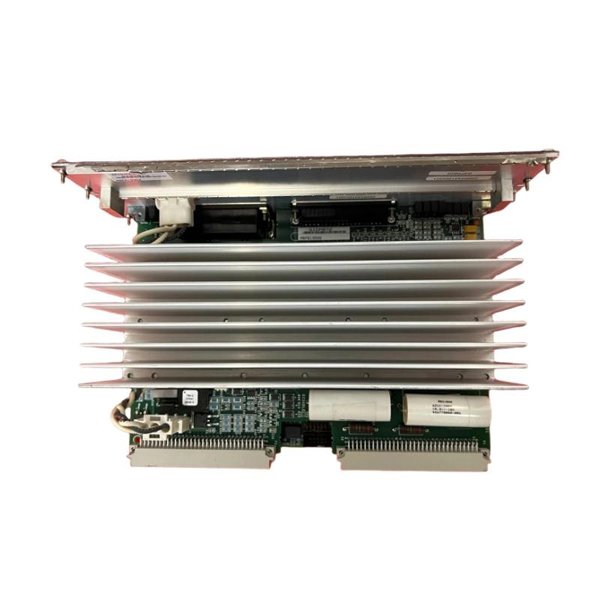

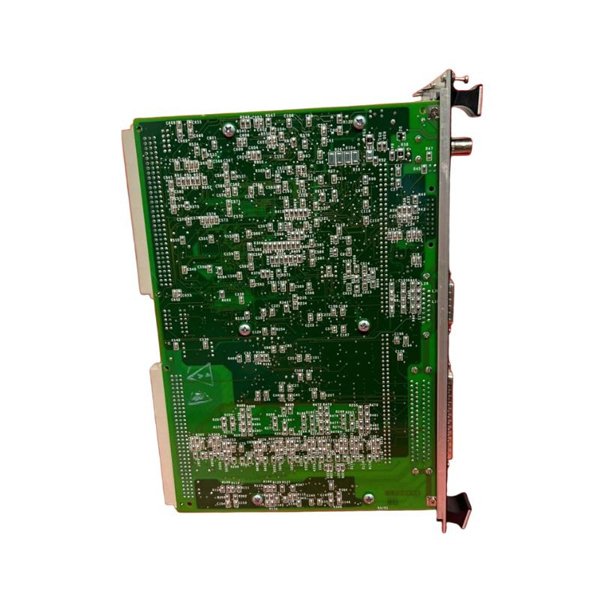

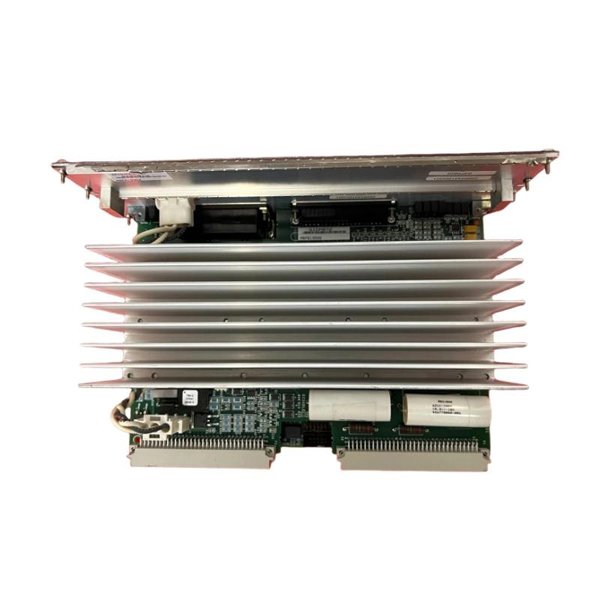

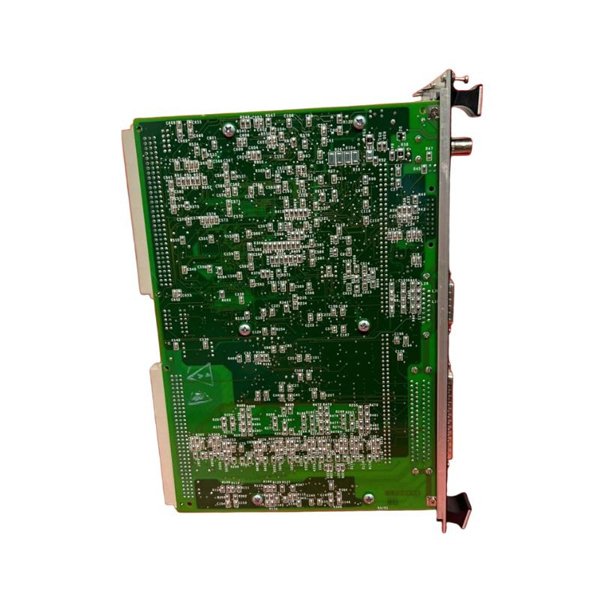

General Electric IS215VPROH1B Turbine Protection Board

Manufacturer:GE

Product Number:IS215VPROH1B

Product Type:Turbine Protection Board

Origin:USA

Dimensions:330 × 100 × 40 mm

Weight:1.2 kg

Views:120

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS215VPROH1B Turbine Protection Board is a specialized control module designed for integration into GE Mark VI and Mark VIe control systems. It serves as a dedicated turbine protection interface, continuously monitoring key turbine parameters and providing rapid shutdown or alarm commands in case of abnormal conditions.

This board is engineered for high reliability, deterministic response, and integration with redundant systems. It processes signals from speed sensors, vibration transducers, temperature probes, and other critical inputs, ensuring that turbine operation remains within safe limits. The IS215VPROH1B is a vital component in safeguarding large industrial turbines, including gas, steam, and combined-cycle systems.

Its modular design, robust construction, and fault-tolerant architecture make it suitable for mission-critical applications, providing operators with dependable real-time protection while minimizing downtime and operational risks.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | IS215VPROH1B |

| Product Type | Turbine Protection Board |

| System Compatibility | GE Mark VI / Mark VIe control systems |

| Input/Output Channels | Multiple speed, vibration, and process analog/digital inputs |

| Protection Functions | Overspeed, vibration, trip logic, and alarm outputs |

| Processing Unit | High-speed digital processor with deterministic control |

| Memory | Onboard RAM and flash for program execution and data storage |

| Power Supply | +5 VDC and +12 VDC via system backplane |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Cooling | Forced-air convection through chassis |

| Mechanical Build | Industrial-grade PCB with reinforced connectors |

| Compliance | CE, UL, CSA certified |

| Dimensions | 330 × 100 × 40 mm |

| Weight | 1.2 kg |

Applications

The IS215VPROH1B is designed for applications requiring precise turbine monitoring and rapid protective action:

-

Gas Turbines: Monitors speed, vibration, and process parameters to prevent catastrophic failure.

-

Steam Turbines: Ensures safe operation by providing overspeed and vibration trip protection.

-

Combined-Cycle Plants: Integrates with multi-unit control architectures for coordinated turbine protection.

-

Industrial Power Plants: Provides safety interlocks and shutdown logic for large turbines.

-

Petrochemical and Refinery Facilities: Protects rotating equipment from abnormal mechanical or process conditions.

-

Research & Test Facilities: Monitors and protects turbines during high-speed performance testing.

Advantages

-

Comprehensive Protection: Monitors multiple parameters to prevent turbine damage.

-

Deterministic Response: Ensures rapid action on overspeed, vibration, or abnormal conditions.

-

Redundancy Support: Compatible with redundant Mark VI/VIe architectures for high reliability.

-

Industrial-Grade Construction: Withstands vibration, thermal, and electrical stress.

-

Modular Design: Simplifies maintenance and board replacement in the control system.

-

Real-Time Processing: Supports immediate protective actions without delay.

-

Seamless Integration: Works with other GE control modules and system components.

-

Certifications: Meets CE, UL, and CSA industrial standards.

FAQ

-

What types of sensors can be connected to this turbine protection board?

It supports speed probes, vibration transducers, temperature sensors, and other analog/digital signals.

-

Which control systems are compatible with the IS215VPROH1B?

GE Mark VI and Mark VIe turbine control systems.

-

Does the board provide overspeed protection?

Yes, it includes dedicated overspeed trip and alarm logic.

-

Can it operate in redundant configurations?

Yes, it supports redundant system architectures for high-reliability turbine protection.

-

How are alarm and trip signals output?

Through onboard relay channels and digital output interfaces integrated with the control system.

-

Does this board process vibration signals?

Yes, it monitors and evaluates vibration inputs in real time for protective action.

-

What kind of power does it require?

It draws +5 VDC and +12 VDC from the system backplane.

-

Is it suitable for high-vibration turbine environments?

Yes, it is built with industrial-grade mechanical resilience for harsh operating conditions.

-

Can firmware be updated on this module?

Yes, firmware is updated using GE system integration and diagnostic tools.

-

What industrial standards does this board comply with?

It meets CE, UL, and CSA certifications for industrial turbine protection applications.

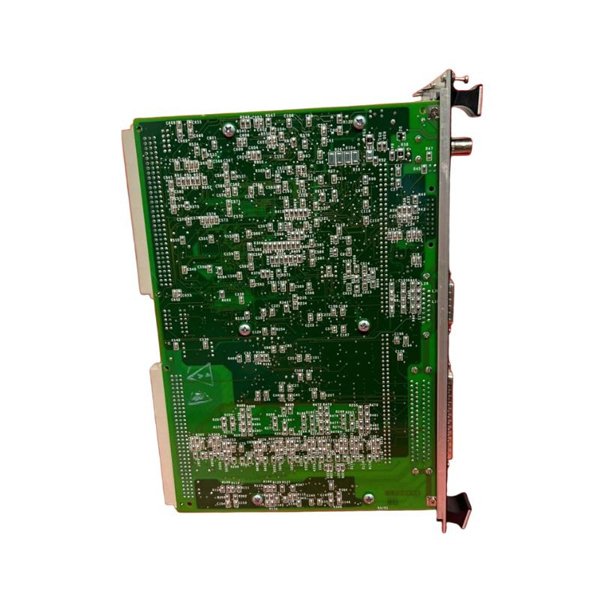

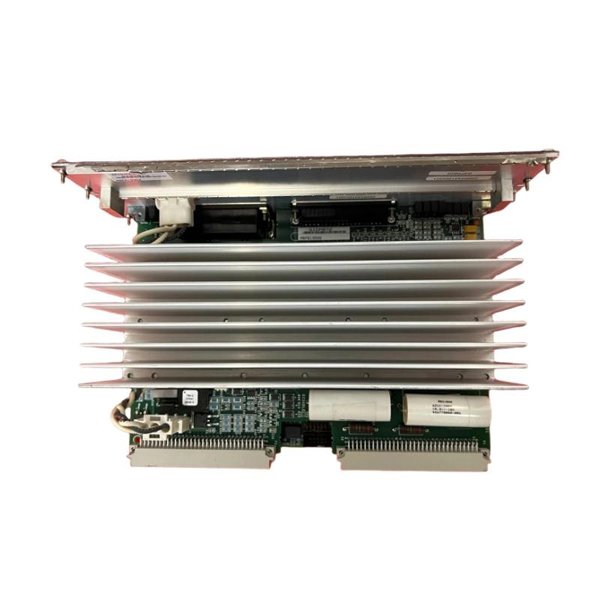

General Electric IS215VPROH1B Turbine Protection Board

Manufacturer:GE

Product Number:IS215VPROH1B

Product Type:Turbine Protection Board

Origin:USA

Dimensions:330 × 100 × 40 mm

Weight:1.2 kg

Views:120

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS215VPROH1B Turbine Protection Board is a specialized control module designed for integration into GE Mark VI and Mark VIe control systems. It serves as a dedicated turbine protection interface, continuously monitoring key turbine parameters and providing rapid shutdown or alarm commands in case of abnormal conditions.

This board is engineered for high reliability, deterministic response, and integration with redundant systems. It processes signals from speed sensors, vibration transducers, temperature probes, and other critical inputs, ensuring that turbine operation remains within safe limits. The IS215VPROH1B is a vital component in safeguarding large industrial turbines, including gas, steam, and combined-cycle systems.

Its modular design, robust construction, and fault-tolerant architecture make it suitable for mission-critical applications, providing operators with dependable real-time protection while minimizing downtime and operational risks.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | IS215VPROH1B |

| Product Type | Turbine Protection Board |

| System Compatibility | GE Mark VI / Mark VIe control systems |

| Input/Output Channels | Multiple speed, vibration, and process analog/digital inputs |

| Protection Functions | Overspeed, vibration, trip logic, and alarm outputs |

| Processing Unit | High-speed digital processor with deterministic control |

| Memory | Onboard RAM and flash for program execution and data storage |

| Power Supply | +5 VDC and +12 VDC via system backplane |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Cooling | Forced-air convection through chassis |

| Mechanical Build | Industrial-grade PCB with reinforced connectors |

| Compliance | CE, UL, CSA certified |

| Dimensions | 330 × 100 × 40 mm |

| Weight | 1.2 kg |

Applications

The IS215VPROH1B is designed for applications requiring precise turbine monitoring and rapid protective action:

-

Gas Turbines: Monitors speed, vibration, and process parameters to prevent catastrophic failure.

-

Steam Turbines: Ensures safe operation by providing overspeed and vibration trip protection.

-

Combined-Cycle Plants: Integrates with multi-unit control architectures for coordinated turbine protection.

-

Industrial Power Plants: Provides safety interlocks and shutdown logic for large turbines.

-

Petrochemical and Refinery Facilities: Protects rotating equipment from abnormal mechanical or process conditions.

-

Research & Test Facilities: Monitors and protects turbines during high-speed performance testing.

Advantages

-

Comprehensive Protection: Monitors multiple parameters to prevent turbine damage.

-

Deterministic Response: Ensures rapid action on overspeed, vibration, or abnormal conditions.

-

Redundancy Support: Compatible with redundant Mark VI/VIe architectures for high reliability.

-

Industrial-Grade Construction: Withstands vibration, thermal, and electrical stress.

-

Modular Design: Simplifies maintenance and board replacement in the control system.

-

Real-Time Processing: Supports immediate protective actions without delay.

-

Seamless Integration: Works with other GE control modules and system components.

-

Certifications: Meets CE, UL, and CSA industrial standards.

FAQ

-

What types of sensors can be connected to this turbine protection board?

It supports speed probes, vibration transducers, temperature sensors, and other analog/digital signals.

-

Which control systems are compatible with the IS215VPROH1B?

GE Mark VI and Mark VIe turbine control systems.

-

Does the board provide overspeed protection?

Yes, it includes dedicated overspeed trip and alarm logic.

-

Can it operate in redundant configurations?

Yes, it supports redundant system architectures for high-reliability turbine protection.

-

How are alarm and trip signals output?

Through onboard relay channels and digital output interfaces integrated with the control system.

-

Does this board process vibration signals?

Yes, it monitors and evaluates vibration inputs in real time for protective action.

-

What kind of power does it require?

It draws +5 VDC and +12 VDC from the system backplane.

-

Is it suitable for high-vibration turbine environments?

Yes, it is built with industrial-grade mechanical resilience for harsh operating conditions.

-

Can firmware be updated on this module?

Yes, firmware is updated using GE system integration and diagnostic tools.

-

What industrial standards does this board comply with?

It meets CE, UL, and CSA certifications for industrial turbine protection applications.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...