Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

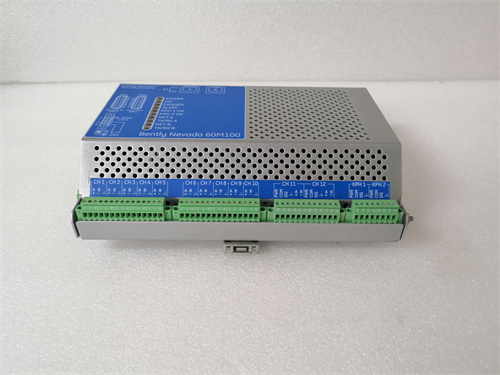

Bently Nevada 330102-00-72-10-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330102-00-72-10-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1m

Weight :0.323 kg

Views:87

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330102-00-72-10-02-05, 3300 XL 8 mm Proximity Probe is a high-performance vibration and position sensing device designed to deliver accurate shaft displacement measurements in critical rotating machinery. This probe belongs to the well-recognized 3300 XL series, which has become a standard in condition monitoring and machinery protection systems.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330102-00-72-10-02-05 |

| Series | 3300 XL 8 mm Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Total Length | 1 m |

| Connector Type | Miniature coaxial, male |

| Mounting Thread | M10 x 1 or 3/8-24 UNF (depending on configuration) |

| Operating Temperature | -35 °C to +177 °C |

| Weight | 0.323 kg |

| Material | Stainless steel probe body, Teflon cable jacket |

| Sensitivity | -200 mV/mil (7.87 mV/µm) typical |

| Linearity Range | 2 mm (80 mils) |

| Compatible Systems | Bently Nevada 3300 XL extension cables and proximitor sensors |

Product Applications

The 3300 XL 8 mm probe is widely deployed in condition monitoring and protection systems for rotating machinery. Typical applications include:

-

Steam turbines and gas turbines – for measuring shaft vibration and axial position.

-

Compressors and pumps – ensuring safe operation by detecting excessive vibration or misalignment.

-

Generators and motors – monitoring shaft behavior to prevent catastrophic failures.

-

Gearboxes – detecting gear mesh issues and shaft instability.

-

Bearings – monitoring clearance, wear, and potential bearing damage.

-

Centrifuges and fans – ensuring stability in high-speed rotating equipment.

Product Advantages

The 3300 XL 8 mm proximity probe offers multiple advantages over conventional probes:

-

High Accuracy – Provides precise measurement of shaft displacement and vibration.

-

Extended Operating Range – Designed to function reliably in high-temperature and high-pressure environments.

-

Durability – Stainless steel construction and Teflon insulation ensure long service life.

-

Compatibility – Fully compatible with other Bently Nevada 3300 XL components for seamless integration.

-

Superior Signal Stability – Low noise levels and excellent immunity to electromagnetic interference.

-

Proven Reliability – Widely adopted across industries, trusted for critical machinery protection.

FAQ

Q1: What is the sensitivity of the 330102-00-72-10-02-05 probe?

A1: The probe has a typical sensitivity of -200 mV/mil (7.87 mV/µm), ensuring precise vibration and displacement readings.

Q2: How does the probe maintain linearity across its measurement range?

A2: The probe is calibrated to maintain a linear output within ±5% across a linear range of 2 mm (80 mils).

Q3: Can the probe operate in high-temperature environments?

A3: Yes, it is rated for continuous operation from -35 °C to +177 °C, making it suitable for demanding conditions.

Q4: How does this probe connect with monitoring systems?

A4: It connects via extension cables to a proximitor sensor, which conditions the signal for Bently Nevada monitoring systems.

Q5: What makes the XL series probes more reliable than standard probes?

A5: The XL series features improved insulation, shielding, and manufacturing quality, ensuring better performance in harsh industrial environments.

Q6: Does the probe require calibration in the field?

A6: No, probes are factory calibrated. Field calibration is generally unnecessary unless system reconfiguration demands it.

Q7: How does the probe handle electromagnetic interference (EMI)?

A7: The coaxial cable and probe construction provide superior EMI shielding, maintaining stable output signals.

Q8: What shaft conditions can this probe detect?

A8: It detects vibration, radial displacement, shaft eccentricity, and axial position changes.

Q9: Is the probe compatible with legacy Bently Nevada systems?

A9: Yes, it is backward compatible with many legacy proximitor sensors, though performance is optimized with 3300 XL components.

Q10: Can the probe withstand exposure to lubricants or chemicals?

A10: Yes, the Teflon-coated cable and stainless-steel probe body are resistant to common industrial fluids and oils.

Bently Nevada 330102-00-72-10-02-05 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330102-00-72-10-02-05

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1m

Weight :0.323 kg

Views:87

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330102-00-72-10-02-05, 3300 XL 8 mm Proximity Probe is a high-performance vibration and position sensing device designed to deliver accurate shaft displacement measurements in critical rotating machinery. This probe belongs to the well-recognized 3300 XL series, which has become a standard in condition monitoring and machinery protection systems.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330102-00-72-10-02-05 |

| Series | 3300 XL 8 mm Proximity Probe |

| Probe Tip Diameter | 8 mm |

| Total Length | 1 m |

| Connector Type | Miniature coaxial, male |

| Mounting Thread | M10 x 1 or 3/8-24 UNF (depending on configuration) |

| Operating Temperature | -35 °C to +177 °C |

| Weight | 0.323 kg |

| Material | Stainless steel probe body, Teflon cable jacket |

| Sensitivity | -200 mV/mil (7.87 mV/µm) typical |

| Linearity Range | 2 mm (80 mils) |

| Compatible Systems | Bently Nevada 3300 XL extension cables and proximitor sensors |

Product Applications

The 3300 XL 8 mm probe is widely deployed in condition monitoring and protection systems for rotating machinery. Typical applications include:

-

Steam turbines and gas turbines – for measuring shaft vibration and axial position.

-

Compressors and pumps – ensuring safe operation by detecting excessive vibration or misalignment.

-

Generators and motors – monitoring shaft behavior to prevent catastrophic failures.

-

Gearboxes – detecting gear mesh issues and shaft instability.

-

Bearings – monitoring clearance, wear, and potential bearing damage.

-

Centrifuges and fans – ensuring stability in high-speed rotating equipment.

Product Advantages

The 3300 XL 8 mm proximity probe offers multiple advantages over conventional probes:

-

High Accuracy – Provides precise measurement of shaft displacement and vibration.

-

Extended Operating Range – Designed to function reliably in high-temperature and high-pressure environments.

-

Durability – Stainless steel construction and Teflon insulation ensure long service life.

-

Compatibility – Fully compatible with other Bently Nevada 3300 XL components for seamless integration.

-

Superior Signal Stability – Low noise levels and excellent immunity to electromagnetic interference.

-

Proven Reliability – Widely adopted across industries, trusted for critical machinery protection.

FAQ

Q1: What is the sensitivity of the 330102-00-72-10-02-05 probe?

A1: The probe has a typical sensitivity of -200 mV/mil (7.87 mV/µm), ensuring precise vibration and displacement readings.

Q2: How does the probe maintain linearity across its measurement range?

A2: The probe is calibrated to maintain a linear output within ±5% across a linear range of 2 mm (80 mils).

Q3: Can the probe operate in high-temperature environments?

A3: Yes, it is rated for continuous operation from -35 °C to +177 °C, making it suitable for demanding conditions.

Q4: How does this probe connect with monitoring systems?

A4: It connects via extension cables to a proximitor sensor, which conditions the signal for Bently Nevada monitoring systems.

Q5: What makes the XL series probes more reliable than standard probes?

A5: The XL series features improved insulation, shielding, and manufacturing quality, ensuring better performance in harsh industrial environments.

Q6: Does the probe require calibration in the field?

A6: No, probes are factory calibrated. Field calibration is generally unnecessary unless system reconfiguration demands it.

Q7: How does the probe handle electromagnetic interference (EMI)?

A7: The coaxial cable and probe construction provide superior EMI shielding, maintaining stable output signals.

Q8: What shaft conditions can this probe detect?

A8: It detects vibration, radial displacement, shaft eccentricity, and axial position changes.

Q9: Is the probe compatible with legacy Bently Nevada systems?

A9: Yes, it is backward compatible with many legacy proximitor sensors, though performance is optimized with 3300 XL components.

Q10: Can the probe withstand exposure to lubricants or chemicals?

A10: Yes, the Teflon-coated cable and stainless-steel probe body are resistant to common industrial fluids and oils.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...