Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

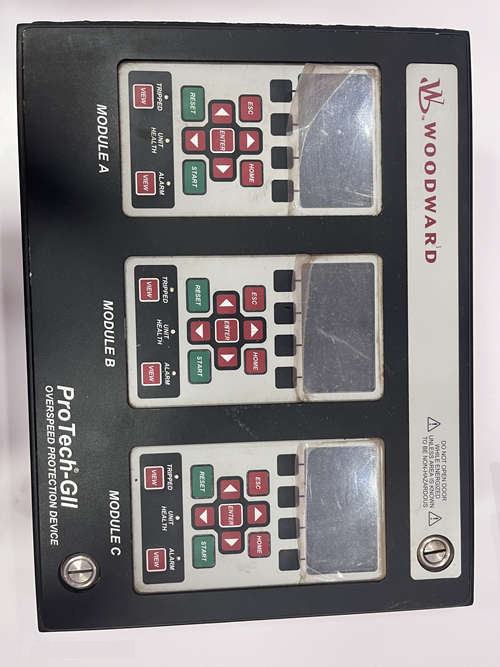

Woodward 9907-147 ProTech 203 Overspeed Protection Device

Manufacturer:Woodward

Product Number:9907-147

Product Type:ProTech 203 Overspeed Protection Device

Origin:USA

Dimensions:485 x 310 x 125 mm

Weight:1.81 kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 9907-147 ProTech 203 Overspeed Protection Device is a critical safety device engineered to detect and react to unsafe turbine or engine speeds. Designed for prime movers such as steam, gas, and hydro turbines, the ProTech 203 ensures rapid shutdown during overspeed events, thus preventing catastrophic mechanical damage and ensuring operational safety.

This triple-redundant, independently powered protection system uses three-speed sensing units and logic processors to monitor input signals, evaluate overspeed conditions, and activate a shutdown command in milliseconds. The ProTech 203 series is compliant with industry safety and redundancy requirements, including API 612, API 670, and IEC standards, making it a trusted solution in mission-critical environments.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | Woodward ProTech 203 ProTech 203 Overspeed Protection Device |

| Model Number | 9907-147 |

| Function | Overspeed detection and shutdown actuation |

| Speed Input Range | 0–25,000 Hz (typical magnetic pickup) |

| Trip Setpoint | Configurable via keypad and display |

| Number of Inputs | 3 (redundant independent speed channels) |

| Power Supply | 18–32 V DC (each of 3 independent power supplies) |

| Relay Outputs | 3 shutdown relays, 3 alarm relays |

| Response Time | < 40 ms (typical trip time) |

| Display | LCD screen with keypad interface |

| Mounting Style | Panel-mounted (rack or enclosure) |

| Operating Temperature | -25°C to +60°C |

| Humidity | 5% to 95% RH, non-condensing |

| Ingress Protection | IP20 (internal use) |

| Certifications | CE, UL/cUL, CSA, ATEX (varies by version) |

| Dimensions (W × H × D) | 432 mm × 177 mm × 250 mm |

| Weight | 1.81 kg |

Product Applications

The Woodward 9907-147 ProTech 203 is widely used in applications where overspeed events pose serious risks to equipment and personnel. Common applications include:

-

Steam Turbines: Primary overspeed shutdown for industrial and utility-scale turbines

-

Gas Turbines: Backup protection for fast-spinning rotor assemblies

-

Hydro Turbines: Monitoring variable-speed generators for overspeed events

-

Compressors and Pumps: Preventing mechanical overrun in high-speed rotating machinery

-

Industrial Engines: Overspeed protection for large reciprocating engines in plants

-

Critical Process Equipment: Compliance with safety standards like API 612, 670, and SIL

Product Advantages

-

Triple-Redundant Safety Architecture

Uses three independent speed-sensing and decision-making channels for maximum reliability.

-

Fast Response Time

Shuts down turbines in under 40 milliseconds during overspeed detection.

-

User-Friendly Configuration

LCD screen and keypad interface allow for on-site configuration, diagnostics, and event logging.

-

Robust System Compatibility

Compatible with magnetic pickups and various power supplies; integrates easily into turbine control panels.

-

Flexible Relay Output Options

Configurable for shutdown, alarm, and system status reporting.

-

Global Safety Compliance

Designed to meet stringent international safety and reliability standards including CE, UL, and API.

Frequently Asked Questions (FAQ)

-

What does the ProTech 203 model 9907-147 protect against?

It protects turbines and engines from overspeed conditions by rapidly initiating a shutdown.

-

How many speed input channels does it use?

The unit uses three independent speed input channels for redundancy.

-

What type of speed sensor can it interface with?

It typically connects to magnetic pickups generating signals up to 25,000 Hz.

-

How is the trip setpoint configured?

Via the built-in keypad and LCD interface, allowing secure on-site adjustments.

-

What is the typical shutdown response time?

Less than 40 milliseconds from overspeed detection to relay actuation.

-

Can this module operate with redundant power supplies?

Yes, it supports three independent power supply inputs for maximum uptime.

-

Is the 9907-147 compliant with API and SIL requirements?

Yes, it is designed to meet API 612, API 670, and IEC functional safety standards.

-

Where is this device typically mounted?

It is usually panel- or rack-mounted in control rooms or turbine enclosures.

-

Does the system include diagnostic features?

Yes, it includes real-time diagnostics, event logging, and system status indicators.

-

Is this system suitable for use in hazardous environments?

Certain versions are ATEX certified for use in explosive or hazardous areas.

Woodward 9907-147 ProTech 203 Overspeed Protection Device

Manufacturer:Woodward

Product Number:9907-147

Product Type:ProTech 203 Overspeed Protection Device

Origin:USA

Dimensions:485 x 310 x 125 mm

Weight:1.81 kg

Views:42

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 9907-147 ProTech 203 Overspeed Protection Device is a critical safety device engineered to detect and react to unsafe turbine or engine speeds. Designed for prime movers such as steam, gas, and hydro turbines, the ProTech 203 ensures rapid shutdown during overspeed events, thus preventing catastrophic mechanical damage and ensuring operational safety.

This triple-redundant, independently powered protection system uses three-speed sensing units and logic processors to monitor input signals, evaluate overspeed conditions, and activate a shutdown command in milliseconds. The ProTech 203 series is compliant with industry safety and redundancy requirements, including API 612, API 670, and IEC standards, making it a trusted solution in mission-critical environments.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | Woodward ProTech 203 ProTech 203 Overspeed Protection Device |

| Model Number | 9907-147 |

| Function | Overspeed detection and shutdown actuation |

| Speed Input Range | 0–25,000 Hz (typical magnetic pickup) |

| Trip Setpoint | Configurable via keypad and display |

| Number of Inputs | 3 (redundant independent speed channels) |

| Power Supply | 18–32 V DC (each of 3 independent power supplies) |

| Relay Outputs | 3 shutdown relays, 3 alarm relays |

| Response Time | < 40 ms (typical trip time) |

| Display | LCD screen with keypad interface |

| Mounting Style | Panel-mounted (rack or enclosure) |

| Operating Temperature | -25°C to +60°C |

| Humidity | 5% to 95% RH, non-condensing |

| Ingress Protection | IP20 (internal use) |

| Certifications | CE, UL/cUL, CSA, ATEX (varies by version) |

| Dimensions (W × H × D) | 432 mm × 177 mm × 250 mm |

| Weight | 1.81 kg |

Product Applications

The Woodward 9907-147 ProTech 203 is widely used in applications where overspeed events pose serious risks to equipment and personnel. Common applications include:

-

Steam Turbines: Primary overspeed shutdown for industrial and utility-scale turbines

-

Gas Turbines: Backup protection for fast-spinning rotor assemblies

-

Hydro Turbines: Monitoring variable-speed generators for overspeed events

-

Compressors and Pumps: Preventing mechanical overrun in high-speed rotating machinery

-

Industrial Engines: Overspeed protection for large reciprocating engines in plants

-

Critical Process Equipment: Compliance with safety standards like API 612, 670, and SIL

Product Advantages

-

Triple-Redundant Safety Architecture

Uses three independent speed-sensing and decision-making channels for maximum reliability.

-

Fast Response Time

Shuts down turbines in under 40 milliseconds during overspeed detection.

-

User-Friendly Configuration

LCD screen and keypad interface allow for on-site configuration, diagnostics, and event logging.

-

Robust System Compatibility

Compatible with magnetic pickups and various power supplies; integrates easily into turbine control panels.

-

Flexible Relay Output Options

Configurable for shutdown, alarm, and system status reporting.

-

Global Safety Compliance

Designed to meet stringent international safety and reliability standards including CE, UL, and API.

Frequently Asked Questions (FAQ)

-

What does the ProTech 203 model 9907-147 protect against?

It protects turbines and engines from overspeed conditions by rapidly initiating a shutdown.

-

How many speed input channels does it use?

The unit uses three independent speed input channels for redundancy.

-

What type of speed sensor can it interface with?

It typically connects to magnetic pickups generating signals up to 25,000 Hz.

-

How is the trip setpoint configured?

Via the built-in keypad and LCD interface, allowing secure on-site adjustments.

-

What is the typical shutdown response time?

Less than 40 milliseconds from overspeed detection to relay actuation.

-

Can this module operate with redundant power supplies?

Yes, it supports three independent power supply inputs for maximum uptime.

-

Is the 9907-147 compliant with API and SIL requirements?

Yes, it is designed to meet API 612, API 670, and IEC functional safety standards.

-

Where is this device typically mounted?

It is usually panel- or rack-mounted in control rooms or turbine enclosures.

-

Does the system include diagnostic features?

Yes, it includes real-time diagnostics, event logging, and system status indicators.

-

Is this system suitable for use in hazardous environments?

Certain versions are ATEX certified for use in explosive or hazardous areas.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...