Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

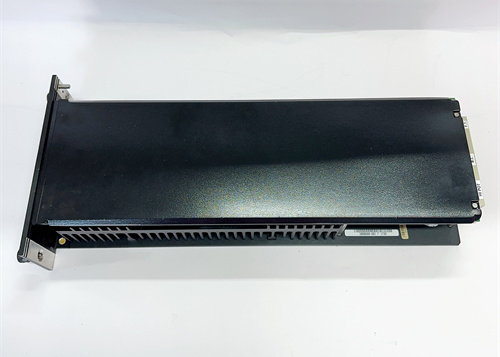

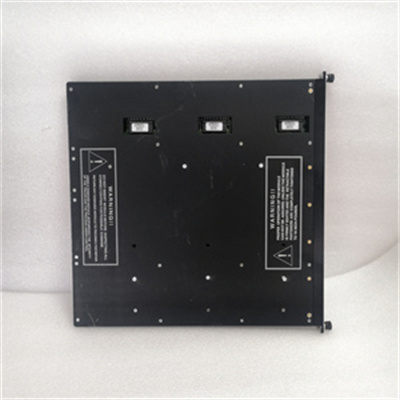

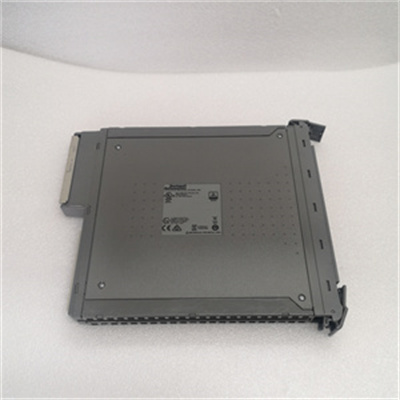

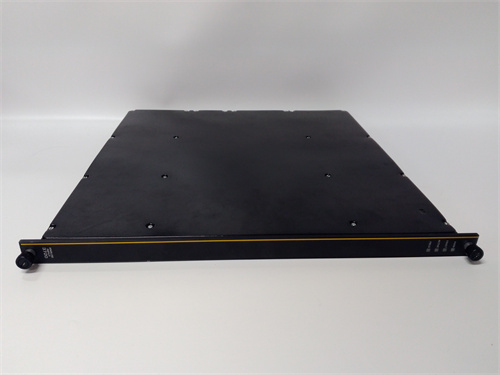

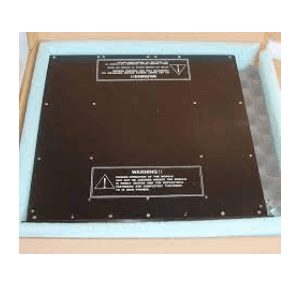

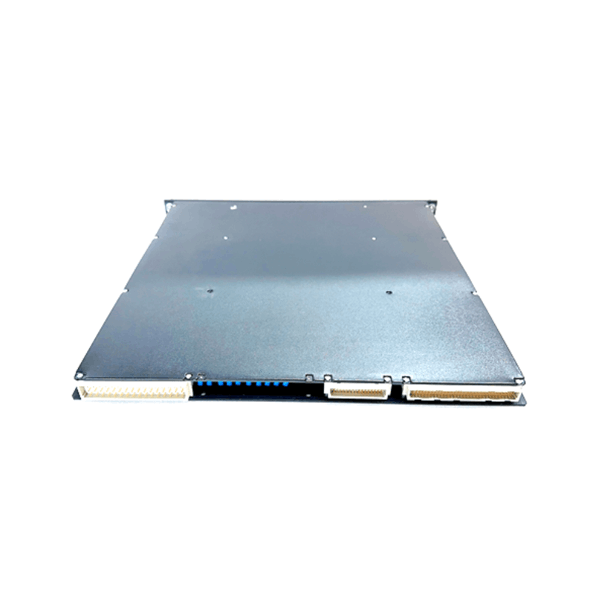

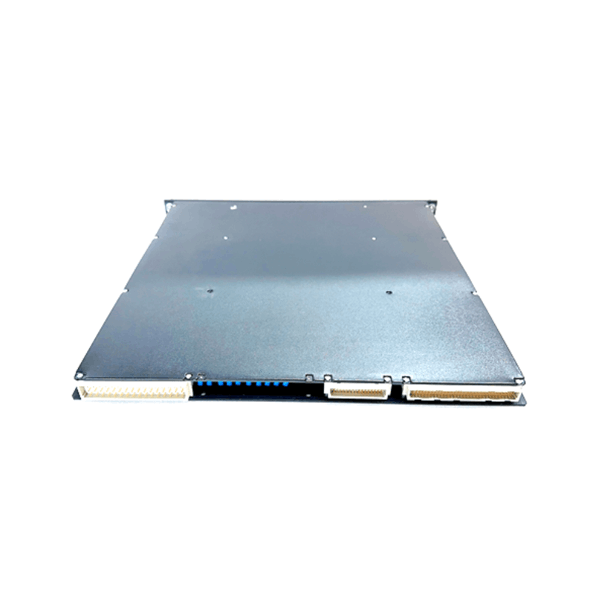

Triconex 3625C1 Digital Output Module

Manufacturer: Invensys Triconex

Product Number:3625C1

Product Type:Digital Output Module

Origin:USA

Dimensions:150 x 120 x 50 mm

Weight:2.06 kg

Views:70

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Invensys Triconex 3625C1 is a digital output module designed for high-integrity safety applications within industrial automation systems. Part of the Triconex series, this module ensures reliable and secure communication between safety instrumented systems (SIS) and field devices, playing a crucial role in maintaining operational safety and efficiency.

Detailed Specifications

Below is a table outlining the key specifications of the Triconex 3625C1 Digital Output Module:

| Specification | Details |

|---|---|

| Manufacturer | Invensys Triconex |

| Model Number | 3625C1 |

| Product Type | Digital Output Module |

| Output Channels | 16 digital output channels |

| Nominal Voltage | 24 VDC |

| Voltage Range | 16-32 VDC |

| Maximum Voltage | 36 VDC |

| Maximum Current per Point | 1.7 A |

| Surge Current | 7 A (10 ms) |

| Minimum Load Requirement | 10 mA |

| Voltage Drop | < 2.8 VDC @ 1.7 A (typical) |

| Power Consumption | < 13 W |

| Isolation Voltage | 1,500 VDC |

| Operating Temperature | -40°C to 85°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 10% to 90% non-condensing |

| Dimensions | 150 x 120 x 50 mm |

| Weight | 2.06 kg |

| Safety Integrity Level | SIL 3 |

| Communication Protocols | Modbus |

| Mounting | DIN rail |

| Enclosure Rating | IP20 (indoor use) |

| Diagnostic Indicators | PASS, FAULT, ACTIVE LEDs |

| Certifications | CE, UL, CSA |

Applications

The Triconex 3625C1 Digital Output Module is utilized in various industrial applications, including:

- Emergency Shutdown Systems (ESD): Ensures safe shutdown of processes during emergencies.

- Fire and Gas Systems: Monitors and controls fire suppression and gas detection systems.

- Turbomachinery Control: Manages operations of turbines and compressors.

- Boiler and Burner Management: Oversees safe operation of boilers and burners.

- Pipeline Management: Controls and monitors pipeline operations to prevent leaks and ruptures.

- Chemical Processing: Regulates chemical reactions and processes safely.

- Power Generation: Manages electrical generation processes in power plants.

- Manufacturing Automation: Controls automated manufacturing processes ensuring safety and efficiency.

Advantages

The Triconex 3625C1 offers several advantages:

- High Reliability: Triple Modular Redundancy (TMR) architecture ensures continuous operation even during component failures.

- Enhanced Safety: Certified to Safety Integrity Level 3 (SIL 3), providing high-level risk reduction.

- Robust Diagnostics: Comprehensive diagnostics for real-time monitoring and fault detection.

- Scalability: Modular design allows easy expansion to accommodate growing system requirements.

- Wide Operating Range: Operates effectively in harsh environmental conditions with a broad temperature range.

- Ease of Integration: Compatible with standard industrial communication protocols like Modbus.

- User-Friendly Maintenance: Diagnostic indicators facilitate quick troubleshooting and maintenance.

- Regulatory Compliance: Meets international safety and quality standards, ensuring compliance with industry regulations.

Frequently Asked Questions (FAQ)

-

What is the primary function of the Invensys Triconex 3625C1 Digital Output Module?

- The Triconex 3625C1 is a digital output module designed to provide 16 independent output channels. It is used to control external devices such as solenoids, relays, actuators, and alarms by providing a 24 VDC output signal. The module ensures safe and reliable signal transmission in industrial safety systems.

-

What type of safety certification does the Triconex 3625C1 have?

- The Triconex 3625C1 is certified for SIL 3 (Safety Integrity Level 3), making it suitable for high-integrity safety applications. This certification ensures that the module meets strict international safety standards and provides reliable protection against failures.

-

What are the electrical specifications for the module’s output channels?

- The module operates at 24 VDC nominal output voltage, with an allowable range between 16 VDC to 32 VDC. Each channel can handle a maximum continuous current of 1.7 A, with a surge current capacity of 7 A (for 10 ms).

-

How does the module ensure reliable operation in case of a fault?

- The 3625C1 is designed with Triple Modular Redundancy (TMR) technology, which enhances system reliability by continuously monitoring itself and automatically switching to a backup system in case of a component failure. This self-checking mechanism ensures uninterrupted operation.

-

What are the diagnostic features available on the Triconex 3625C1?

- The module includes built-in LED indicators that provide real-time status updates. The indicators show the module’s operational state, whether it is active, faulty, or functioning correctly. Additionally, the system’s self-diagnostic functions help detect issues early, reducing downtime and maintenance costs.

-

What are the environmental specifications of the Triconex 3625C1?

- The module is designed for harsh industrial environments and operates within a temperature range of -40°C to 85°C. It is also rated for humidity levels of 10% to 90% (non-condensing), ensuring stability in challenging conditions such as chemical plants, oil refineries, and power plants.

-

What communication protocols does the Triconex 3625C1 support?

- The module is designed for seamless integration into industrial systems and supports the Modbus communication protocol. This enables easy interfacing with other automation and control systems, making it suitable for distributed control systems (DCS) and safety instrumented systems (SIS).

-

What are the mounting and installation requirements for the Triconex 3625C1?

- The module is DIN-rail mountable, which allows for easy installation in standard control cabinets. It is designed to fit into Triconex safety systems with minimal wiring requirements, reducing installation time and effort.

-

What industries commonly use the Triconex 3625C1 Digital Output Module?

-

This module is widely used in industries that require high-reliability safety systems, including:

- Oil and Gas – Emergency shutdown (ESD) and fire/gas detection systems.

- Power Generation – Boiler safety and turbine control.

- Chemical Processing – Reactor control and hazardous material handling.

- Manufacturing – Factory automation and conveyor system safety.

-

This module is widely used in industries that require high-reliability safety systems, including:

-

What is the expected lifespan of the Triconex 3625C1 module?

- It utilizes Triple Modular Redundancy (TMR) architecture, allowing continuous operation even if a component fails.

Triconex 3625C1 Digital Output Module

Manufacturer: Invensys Triconex

Product Number:3625C1

Product Type:Digital Output Module

Origin:USA

Dimensions:150 x 120 x 50 mm

Weight:2.06 kg

Views:70

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Invensys Triconex 3625C1 is a digital output module designed for high-integrity safety applications within industrial automation systems. Part of the Triconex series, this module ensures reliable and secure communication between safety instrumented systems (SIS) and field devices, playing a crucial role in maintaining operational safety and efficiency.

Detailed Specifications

Below is a table outlining the key specifications of the Triconex 3625C1 Digital Output Module:

| Specification | Details |

|---|---|

| Manufacturer | Invensys Triconex |

| Model Number | 3625C1 |

| Product Type | Digital Output Module |

| Output Channels | 16 digital output channels |

| Nominal Voltage | 24 VDC |

| Voltage Range | 16-32 VDC |

| Maximum Voltage | 36 VDC |

| Maximum Current per Point | 1.7 A |

| Surge Current | 7 A (10 ms) |

| Minimum Load Requirement | 10 mA |

| Voltage Drop | < 2.8 VDC @ 1.7 A (typical) |

| Power Consumption | < 13 W |

| Isolation Voltage | 1,500 VDC |

| Operating Temperature | -40°C to 85°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 10% to 90% non-condensing |

| Dimensions | 150 x 120 x 50 mm |

| Weight | 2.06 kg |

| Safety Integrity Level | SIL 3 |

| Communication Protocols | Modbus |

| Mounting | DIN rail |

| Enclosure Rating | IP20 (indoor use) |

| Diagnostic Indicators | PASS, FAULT, ACTIVE LEDs |

| Certifications | CE, UL, CSA |

Applications

The Triconex 3625C1 Digital Output Module is utilized in various industrial applications, including:

- Emergency Shutdown Systems (ESD): Ensures safe shutdown of processes during emergencies.

- Fire and Gas Systems: Monitors and controls fire suppression and gas detection systems.

- Turbomachinery Control: Manages operations of turbines and compressors.

- Boiler and Burner Management: Oversees safe operation of boilers and burners.

- Pipeline Management: Controls and monitors pipeline operations to prevent leaks and ruptures.

- Chemical Processing: Regulates chemical reactions and processes safely.

- Power Generation: Manages electrical generation processes in power plants.

- Manufacturing Automation: Controls automated manufacturing processes ensuring safety and efficiency.

Advantages

The Triconex 3625C1 offers several advantages:

- High Reliability: Triple Modular Redundancy (TMR) architecture ensures continuous operation even during component failures.

- Enhanced Safety: Certified to Safety Integrity Level 3 (SIL 3), providing high-level risk reduction.

- Robust Diagnostics: Comprehensive diagnostics for real-time monitoring and fault detection.

- Scalability: Modular design allows easy expansion to accommodate growing system requirements.

- Wide Operating Range: Operates effectively in harsh environmental conditions with a broad temperature range.

- Ease of Integration: Compatible with standard industrial communication protocols like Modbus.

- User-Friendly Maintenance: Diagnostic indicators facilitate quick troubleshooting and maintenance.

- Regulatory Compliance: Meets international safety and quality standards, ensuring compliance with industry regulations.

Frequently Asked Questions (FAQ)

-

What is the primary function of the Invensys Triconex 3625C1 Digital Output Module?

- The Triconex 3625C1 is a digital output module designed to provide 16 independent output channels. It is used to control external devices such as solenoids, relays, actuators, and alarms by providing a 24 VDC output signal. The module ensures safe and reliable signal transmission in industrial safety systems.

-

What type of safety certification does the Triconex 3625C1 have?

- The Triconex 3625C1 is certified for SIL 3 (Safety Integrity Level 3), making it suitable for high-integrity safety applications. This certification ensures that the module meets strict international safety standards and provides reliable protection against failures.

-

What are the electrical specifications for the module’s output channels?

- The module operates at 24 VDC nominal output voltage, with an allowable range between 16 VDC to 32 VDC. Each channel can handle a maximum continuous current of 1.7 A, with a surge current capacity of 7 A (for 10 ms).

-

How does the module ensure reliable operation in case of a fault?

- The 3625C1 is designed with Triple Modular Redundancy (TMR) technology, which enhances system reliability by continuously monitoring itself and automatically switching to a backup system in case of a component failure. This self-checking mechanism ensures uninterrupted operation.

-

What are the diagnostic features available on the Triconex 3625C1?

- The module includes built-in LED indicators that provide real-time status updates. The indicators show the module’s operational state, whether it is active, faulty, or functioning correctly. Additionally, the system’s self-diagnostic functions help detect issues early, reducing downtime and maintenance costs.

-

What are the environmental specifications of the Triconex 3625C1?

- The module is designed for harsh industrial environments and operates within a temperature range of -40°C to 85°C. It is also rated for humidity levels of 10% to 90% (non-condensing), ensuring stability in challenging conditions such as chemical plants, oil refineries, and power plants.

-

What communication protocols does the Triconex 3625C1 support?

- The module is designed for seamless integration into industrial systems and supports the Modbus communication protocol. This enables easy interfacing with other automation and control systems, making it suitable for distributed control systems (DCS) and safety instrumented systems (SIS).

-

What are the mounting and installation requirements for the Triconex 3625C1?

- The module is DIN-rail mountable, which allows for easy installation in standard control cabinets. It is designed to fit into Triconex safety systems with minimal wiring requirements, reducing installation time and effort.

-

What industries commonly use the Triconex 3625C1 Digital Output Module?

-

This module is widely used in industries that require high-reliability safety systems, including:

- Oil and Gas – Emergency shutdown (ESD) and fire/gas detection systems.

- Power Generation – Boiler safety and turbine control.

- Chemical Processing – Reactor control and hazardous material handling.

- Manufacturing – Factory automation and conveyor system safety.

-

This module is widely used in industries that require high-reliability safety systems, including:

-

What is the expected lifespan of the Triconex 3625C1 module?

- It utilizes Triple Modular Redundancy (TMR) architecture, allowing continuous operation even if a component fails.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...