Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

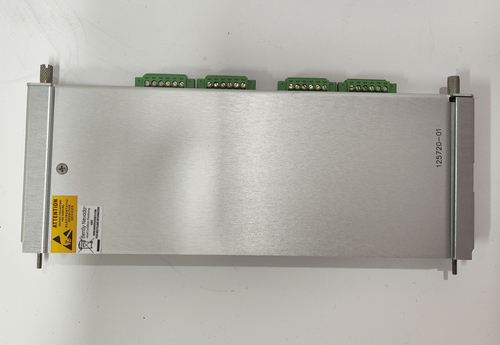

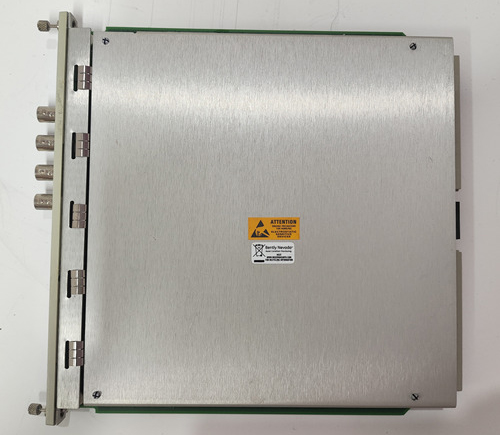

Bently Nevada 330901-00-96-10-02-05 3300 NSv Proximity Probe

Manufacturer:Bently Nevada

Product Number:330901-00-96-10-02-05

Product Type:3300 NSv Proximity Probe

Origin:USA

Total Length:1m

Weight:3 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330901-00-96-10-02-05 is a high-precision proximity probe designed for vibration and displacement measurements in critical machinery applications. As part of Bently Nevada’s well-known 3300 XL series, this sensor is tailored to detect mechanical vibrations and shaft displacement, providing accurate data for machinery health monitoring. It is commonly used in industries such as power generation, petrochemical, and heavy manufacturing, where equipment reliability is paramount.

Bently Nevada is renowned for its reliable and advanced monitoring solutions, and the 330901-00-96-10-02-05 probe exemplifies this by offering robust performance in demanding environments. It features a flexible design that can be integrated with various monitoring systems, delivering real-time insights into machine condition and enabling predictive maintenance.

Product Specifications

| Specification | Value |

|---|---|

| Model | 330901-00-96-10-02-05 |

| Type | Proximity Probe |

| Application | Vibration/Displacement Measurement |

| Operating Temperature | -40°C to +100°C |

| Measurement Range | 0 to 25 mm |

| Weight | 3 kg |

| Total Length | 1 m |

| Material | Stainless Steel |

| Compatibility | Bently Nevada 3300 XL series systems |

Product Applications

The Bently Nevada 330901-00-96-10-02-05 is primarily used for monitoring the health of rotating machinery such as turbines, compressors, pumps, and motors. Some of the key applications include:

-

Vibration Monitoring: Measures radial displacement or shaft movement to identify issues like imbalance, misalignment, and bearing defects.

-

Condition Monitoring Systems: Integrated into machine monitoring systems to help operators prevent unplanned downtime by identifying faults early.

-

Predictive Maintenance: Provides real-time feedback to predict machinery failure before it happens, reducing maintenance costs and improving equipment life.

-

Automation and Control Systems: Used in automated systems where machinery health data is critical to process control.

Product Advantages

-

High Accuracy: The 330901-00-96-10-02-05 offers precise measurements for accurate vibration and displacement data.

-

Durability: Designed to operate in harsh environments, with resistance to extreme temperatures and mechanical stresses.

-

Ease of Integration: Easily integrates with existing Bently Nevada monitoring systems for enhanced equipment monitoring.

-

Wide Application Range: Suitable for a variety of industries, including energy, manufacturing, and transportation.

-

Real-Time Data: Provides real-time data, enabling quick response to potential issues and minimizing downtime.

-

Long Service Life: Built with high-quality materials for a long operational life, reducing replacement costs.

FAQ

Q1: What is the primary function of the Bently Nevada 330901-00-96-10-02-05 probe?

A1: The primary function is to measure vibration and displacement in rotating machinery, enabling early fault detection and preventing unexpected downtime.

Q2: Can this probe be used for both radial and axial measurements?

A2: Yes, the probe is designed to measure radial displacement effectively. For axial measurements, a different probe may be required.

Q3: What industries typically use this product?

A3: Industries like power generation, petrochemical, and heavy manufacturing use this probe for machinery health monitoring.

Q4: How is the data from this probe used in maintenance strategies?

A4: The data is integrated into predictive maintenance systems, helping to identify issues before they lead to failure, thus reducing maintenance costs and improving reliability.

Q5: What is the maximum measurement range of this proximity probe?

A5: The maximum measurement range of the 330901-00-96-10-02-05 is 25 mm.

Q6: What is the temperature range that this probe can operate in?

A6: The probe operates effectively within a temperature range of -40°C to +100°C.

Q7: Is this probe compatible with older Bently Nevada systems?

A7: Yes, the 330901-00-96-10-02-05 is designed to be compatible with the 3300 XL series, which integrates well with older systems as well.

Q8: What material is the Bently Nevada 330901-00-96-10-02-05 probe made from?

A8: The probe is made from stainless steel, which enhances its durability and resistance to wear.

Q9: Can this probe detect misalignment or imbalance in machinery?

A9: Yes, the 330901-00-96-10-02-05 can detect issues like misalignment and imbalance by measuring displacement and vibration.

Q10: How do I install the Bently Nevada 330901-00-96-10-02-05 probe?

A10: Installation requires mounting the probe onto the machinery at the appropriate measurement point. The system should be calibrated according to the manufacturer’s guidelines to ensure accurate readings.

Bently Nevada 330901-00-96-10-02-05 3300 NSv Proximity Probe

Manufacturer:Bently Nevada

Product Number:330901-00-96-10-02-05

Product Type:3300 NSv Proximity Probe

Origin:USA

Total Length:1m

Weight:3 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330901-00-96-10-02-05 is a high-precision proximity probe designed for vibration and displacement measurements in critical machinery applications. As part of Bently Nevada’s well-known 3300 XL series, this sensor is tailored to detect mechanical vibrations and shaft displacement, providing accurate data for machinery health monitoring. It is commonly used in industries such as power generation, petrochemical, and heavy manufacturing, where equipment reliability is paramount.

Bently Nevada is renowned for its reliable and advanced monitoring solutions, and the 330901-00-96-10-02-05 probe exemplifies this by offering robust performance in demanding environments. It features a flexible design that can be integrated with various monitoring systems, delivering real-time insights into machine condition and enabling predictive maintenance.

Product Specifications

| Specification | Value |

|---|---|

| Model | 330901-00-96-10-02-05 |

| Type | Proximity Probe |

| Application | Vibration/Displacement Measurement |

| Operating Temperature | -40°C to +100°C |

| Measurement Range | 0 to 25 mm |

| Weight | 3 kg |

| Total Length | 1 m |

| Material | Stainless Steel |

| Compatibility | Bently Nevada 3300 XL series systems |

Product Applications

The Bently Nevada 330901-00-96-10-02-05 is primarily used for monitoring the health of rotating machinery such as turbines, compressors, pumps, and motors. Some of the key applications include:

-

Vibration Monitoring: Measures radial displacement or shaft movement to identify issues like imbalance, misalignment, and bearing defects.

-

Condition Monitoring Systems: Integrated into machine monitoring systems to help operators prevent unplanned downtime by identifying faults early.

-

Predictive Maintenance: Provides real-time feedback to predict machinery failure before it happens, reducing maintenance costs and improving equipment life.

-

Automation and Control Systems: Used in automated systems where machinery health data is critical to process control.

Product Advantages

-

High Accuracy: The 330901-00-96-10-02-05 offers precise measurements for accurate vibration and displacement data.

-

Durability: Designed to operate in harsh environments, with resistance to extreme temperatures and mechanical stresses.

-

Ease of Integration: Easily integrates with existing Bently Nevada monitoring systems for enhanced equipment monitoring.

-

Wide Application Range: Suitable for a variety of industries, including energy, manufacturing, and transportation.

-

Real-Time Data: Provides real-time data, enabling quick response to potential issues and minimizing downtime.

-

Long Service Life: Built with high-quality materials for a long operational life, reducing replacement costs.

FAQ

Q1: What is the primary function of the Bently Nevada 330901-00-96-10-02-05 probe?

A1: The primary function is to measure vibration and displacement in rotating machinery, enabling early fault detection and preventing unexpected downtime.

Q2: Can this probe be used for both radial and axial measurements?

A2: Yes, the probe is designed to measure radial displacement effectively. For axial measurements, a different probe may be required.

Q3: What industries typically use this product?

A3: Industries like power generation, petrochemical, and heavy manufacturing use this probe for machinery health monitoring.

Q4: How is the data from this probe used in maintenance strategies?

A4: The data is integrated into predictive maintenance systems, helping to identify issues before they lead to failure, thus reducing maintenance costs and improving reliability.

Q5: What is the maximum measurement range of this proximity probe?

A5: The maximum measurement range of the 330901-00-96-10-02-05 is 25 mm.

Q6: What is the temperature range that this probe can operate in?

A6: The probe operates effectively within a temperature range of -40°C to +100°C.

Q7: Is this probe compatible with older Bently Nevada systems?

A7: Yes, the 330901-00-96-10-02-05 is designed to be compatible with the 3300 XL series, which integrates well with older systems as well.

Q8: What material is the Bently Nevada 330901-00-96-10-02-05 probe made from?

A8: The probe is made from stainless steel, which enhances its durability and resistance to wear.

Q9: Can this probe detect misalignment or imbalance in machinery?

A9: Yes, the 330901-00-96-10-02-05 can detect issues like misalignment and imbalance by measuring displacement and vibration.

Q10: How do I install the Bently Nevada 330901-00-96-10-02-05 probe?

A10: Installation requires mounting the probe onto the machinery at the appropriate measurement point. The system should be calibrated according to the manufacturer’s guidelines to ensure accurate readings.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...