Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

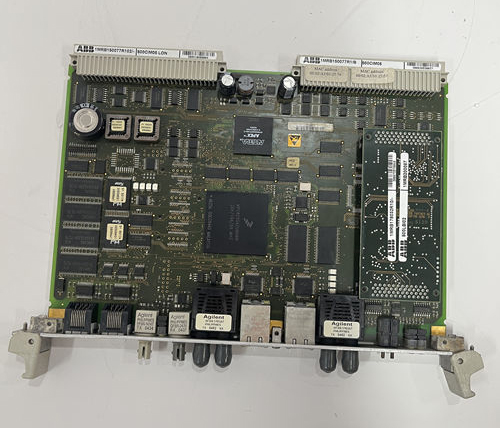

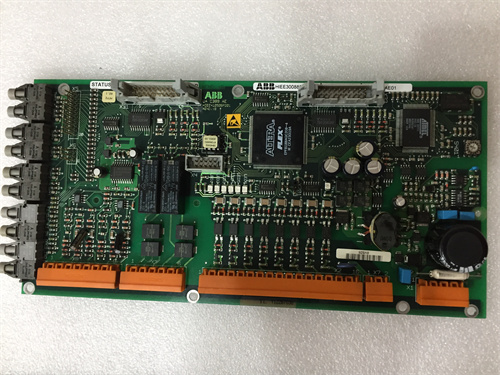

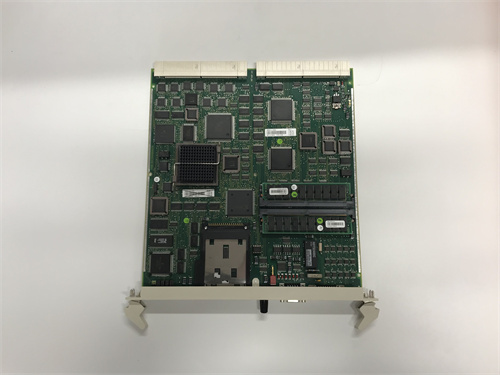

ABB PM151 3BSE003642R1 CPU Board Card

Manufacturer:ABB

Product Number:PM151 3BSE003642R1

Product Type:CPU Board Card

Origin:Sweden

Dimensions:24 × 125 × 120 mm

Weight:0.35 kg

Views:29

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PM151 3BSE003642R1 is a compact and powerful CPU board module used within ABB’s proven automation platforms. Engineered for use in ABB’s Advant Controller 31 systems, this CPU card serves as the central processing unit, handling all control logic, communication with field devices, and internal signal processing. Designed for performance, stability, and long lifecycle support, the PM151 is an integral part of distributed control systems used in demanding industrial environments.

With robust support for I/O modules, high-speed processing, and multiple communication interfaces, the PM151 ensures accurate execution of control tasks, efficient data handling, and integration with supervisory control systems. This unit is widely trusted in process automation, utilities, and manufacturing sectors.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | PM151 |

| Part Number | 3BSE003642R1 |

| Product Type | CPU Board / Processor Module |

| System Platform | Advant Controller 31 |

| Processor Type | Embedded 32-bit processor |

| Internal Memory | 512 KB RAM, 256 KB Flash |

| Program Execution Speed | Real-time processing (cyclic, interrupt) |

| Communication Interfaces | RS232, RS485, Advant Fieldbus 100 |

| Supported Protocols | MODBUS, ABB Advant Protocols |

| Mounting Type | Rack/DIN-rail mounting (via base unit) |

| Power Supply Requirement | 5V DC |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95% non-condensing |

| Dimensions (L × W × H) | 24 × 125 × 120 mm |

| Weight | 0.35 kg |

Applications

The PM151 CPU board is primarily used in industrial automation systems and distributed control systems (DCS). Key application areas include:

-

Power Generation Facilities – Turbine control, excitation, and auxiliary system management

-

Water and Wastewater Treatment Plants – Real-time pump and valve control

-

Oil and Gas Production – Process control in refineries and off-shore platforms

-

Chemical and Pharmaceutical Industries – Batch process regulation and monitoring

-

Food and Beverage Manufacturing – Sequential control and process consistency

-

Paper and Pulp Mills – Drive and process line automation

-

Metal Processing – Furnace, rolling mill, and treatment line automation

Product Advantages

-

Reliable Real-time Control – The PM151 is designed for deterministic, real-time processing, ensuring stable and accurate execution of critical industrial processes.

-

Integrated Communication Options – Built-in interfaces allow seamless data exchange with remote I/O and SCADA systems using industrial protocols.

-

Modular Compatibility – Fully compatible with Advant Controller 31 series modules and expansions, offering flexible system upgrades.

-

Long Operational Life – Built to withstand continuous operation under harsh conditions, with high resistance to vibration and temperature changes.

-

Low Power Consumption – Efficient design reduces power requirements and minimizes heat generation.

-

ABB Software Ecosystem Support – Easily configurable via ABB’s engineering tools like Composer or Advant Control Builder.

-

Ease of Maintenance – Diagnostic LEDs and modular layout facilitate rapid troubleshooting and replacement.

-

Conformal Coating Protection – PCB is protected against moisture and contaminants for field longevity.

-

Compact Form Factor – Ideal for use in dense or limited-space panel installations.

-

Global Support & Spare Availability – Backed by ABB’s worldwide support and supply chain infrastructure.

Frequently Asked Questions (FAQ)

-

Can PM151 be directly replaced with PM152 or PM153 without software changes?

No. Each CPU version may have different memory capacities and instruction handling. Software adjustments or validations are required during migration.

-

Is PM151 suitable for new system installations or just for legacy systems?

While mainly used for legacy Advant Controller 31 platforms, it is still deployed in systems requiring proven reliability and backward compatibility.

-

How do I connect PM151 to a supervisory SCADA system?

Use the RS232 or RS485 interface along with MODBUS protocol. Ensure proper addressing and baud rate settings.

-

Does PM151 support redundancy configurations?

Redundancy is not native to PM151 but can be achieved at the system level using dual-controller architecture and ABB’s redundancy modules.

-

How is the firmware updated on this CPU card?

Firmware updates are done via serial connection using ABB’s proprietary configuration software.

-

What is the difference between PM151 and PM154?

PM154 typically has higher processing capabilities, more memory, and advanced diagnostics, while PM151 is the standard entry-level CPU board.

-

Is there protection against static discharge during installation?

Yes, but installers should always use ESD protection such as wrist straps to avoid board damage.

-

What happens if the PM151 overheats or operates above 60°C?

Prolonged exposure can degrade performance or cause failure. Install in a ventilated cabinet or use cooling elements for thermal management.

-

How is the system diagnosed if the CPU does not respond?

LED indicators provide quick diagnostics. ABB’s service tools can also retrieve fault logs if communication is partially available.

-

Can I use third-party modules with PM151?

Only ABB-certified modules are recommended. Third-party components may cause incompatibility issues or violate safety certifications.

ABB PM151 3BSE003642R1 CPU Board Card

Manufacturer:ABB

Product Number:PM151 3BSE003642R1

Product Type:CPU Board Card

Origin:Sweden

Dimensions:24 × 125 × 120 mm

Weight:0.35 kg

Views:29

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The ABB PM151 3BSE003642R1 is a compact and powerful CPU board module used within ABB’s proven automation platforms. Engineered for use in ABB’s Advant Controller 31 systems, this CPU card serves as the central processing unit, handling all control logic, communication with field devices, and internal signal processing. Designed for performance, stability, and long lifecycle support, the PM151 is an integral part of distributed control systems used in demanding industrial environments.

With robust support for I/O modules, high-speed processing, and multiple communication interfaces, the PM151 ensures accurate execution of control tasks, efficient data handling, and integration with supervisory control systems. This unit is widely trusted in process automation, utilities, and manufacturing sectors.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | PM151 |

| Part Number | 3BSE003642R1 |

| Product Type | CPU Board / Processor Module |

| System Platform | Advant Controller 31 |

| Processor Type | Embedded 32-bit processor |

| Internal Memory | 512 KB RAM, 256 KB Flash |

| Program Execution Speed | Real-time processing (cyclic, interrupt) |

| Communication Interfaces | RS232, RS485, Advant Fieldbus 100 |

| Supported Protocols | MODBUS, ABB Advant Protocols |

| Mounting Type | Rack/DIN-rail mounting (via base unit) |

| Power Supply Requirement | 5V DC |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5%–95% non-condensing |

| Dimensions (L × W × H) | 24 × 125 × 120 mm |

| Weight | 0.35 kg |

Applications

The PM151 CPU board is primarily used in industrial automation systems and distributed control systems (DCS). Key application areas include:

-

Power Generation Facilities – Turbine control, excitation, and auxiliary system management

-

Water and Wastewater Treatment Plants – Real-time pump and valve control

-

Oil and Gas Production – Process control in refineries and off-shore platforms

-

Chemical and Pharmaceutical Industries – Batch process regulation and monitoring

-

Food and Beverage Manufacturing – Sequential control and process consistency

-

Paper and Pulp Mills – Drive and process line automation

-

Metal Processing – Furnace, rolling mill, and treatment line automation

Product Advantages

-

Reliable Real-time Control – The PM151 is designed for deterministic, real-time processing, ensuring stable and accurate execution of critical industrial processes.

-

Integrated Communication Options – Built-in interfaces allow seamless data exchange with remote I/O and SCADA systems using industrial protocols.

-

Modular Compatibility – Fully compatible with Advant Controller 31 series modules and expansions, offering flexible system upgrades.

-

Long Operational Life – Built to withstand continuous operation under harsh conditions, with high resistance to vibration and temperature changes.

-

Low Power Consumption – Efficient design reduces power requirements and minimizes heat generation.

-

ABB Software Ecosystem Support – Easily configurable via ABB’s engineering tools like Composer or Advant Control Builder.

-

Ease of Maintenance – Diagnostic LEDs and modular layout facilitate rapid troubleshooting and replacement.

-

Conformal Coating Protection – PCB is protected against moisture and contaminants for field longevity.

-

Compact Form Factor – Ideal for use in dense or limited-space panel installations.

-

Global Support & Spare Availability – Backed by ABB’s worldwide support and supply chain infrastructure.

Frequently Asked Questions (FAQ)

-

Can PM151 be directly replaced with PM152 or PM153 without software changes?

No. Each CPU version may have different memory capacities and instruction handling. Software adjustments or validations are required during migration.

-

Is PM151 suitable for new system installations or just for legacy systems?

While mainly used for legacy Advant Controller 31 platforms, it is still deployed in systems requiring proven reliability and backward compatibility.

-

How do I connect PM151 to a supervisory SCADA system?

Use the RS232 or RS485 interface along with MODBUS protocol. Ensure proper addressing and baud rate settings.

-

Does PM151 support redundancy configurations?

Redundancy is not native to PM151 but can be achieved at the system level using dual-controller architecture and ABB’s redundancy modules.

-

How is the firmware updated on this CPU card?

Firmware updates are done via serial connection using ABB’s proprietary configuration software.

-

What is the difference between PM151 and PM154?

PM154 typically has higher processing capabilities, more memory, and advanced diagnostics, while PM151 is the standard entry-level CPU board.

-

Is there protection against static discharge during installation?

Yes, but installers should always use ESD protection such as wrist straps to avoid board damage.

-

What happens if the PM151 overheats or operates above 60°C?

Prolonged exposure can degrade performance or cause failure. Install in a ventilated cabinet or use cooling elements for thermal management.

-

How is the system diagnosed if the CPU does not respond?

LED indicators provide quick diagnostics. ABB’s service tools can also retrieve fault logs if communication is partially available.

-

Can I use third-party modules with PM151?

Only ABB-certified modules are recommended. Third-party components may cause incompatibility issues or violate safety certifications.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...