Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

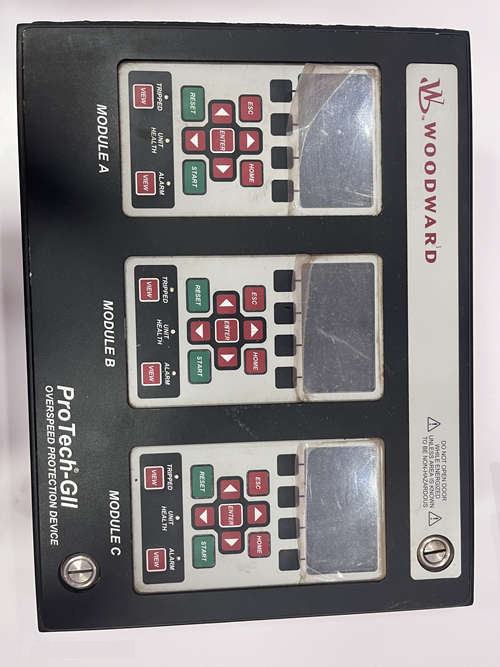

Woodward 8446-1048 Remote Control And Annunciation Panel

Manufacturer:Woodward

Product Number:8446-1048

Product Type:Remote Control And Annunciation Panel

Origin:USA

Dimensions:282 x 217 x 67 mm

Weight:1.3 kg

Views:4

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 8446-1048 Remote Control and Annunciation Panel is an advanced operator interface designed to provide remote monitoring, control, and annunciation functions for engine, turbine, and generator management systems. It allows operators to access real-time system data, respond to alarms, and issue commands without being physically present at the primary controller.

This panel is built with rugged industrial-grade components to ensure durability in harsh environments such as power generation facilities, marine applications, oil and gas plants, and industrial automation systems. By combining remote control capability with detailed annunciation, it improves operational efficiency, enhances safety, and provides operators with situational awareness at all times.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 8446-1048 |

| Product Type | Remote Control and Annunciation Panel |

| Display | High-resolution LCD with status indicators |

| Control Features | Start/stop commands, mode switching, alarm acknowledgement |

| Annunciation Functions | Visual and audible alarm indication |

| Communication Ports | RS-232, RS-485, Ethernet |

| Supported Protocols | Modbus TCP/IP, Modbus RTU, CANbus |

| Input Methods | Keypad and function buttons |

| Processor | Industrial-grade embedded controller |

| Memory | Non-volatile storage for configuration and event logs |

| Power Supply | 24 VDC nominal |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Certifications | CE, UL, CSA, marine approvals |

| Dimensions | 282 x 217 x 67 mm |

| Weight | 1.3 kg |

| Mounting | Panel-mounted |

| Diagnostics | Built-in self-test, error codes, alarm history |

Applications

The 8446-1048 Remote Control and Annunciation Panel is suitable for a wide range of applications where remote access and monitoring are essential:

-

Power Generation Plants – Allows operators to control and monitor generators and auxiliary equipment.

-

Oil & Gas Facilities – Provides safe and efficient monitoring of critical process equipment.

-

Marine Applications – Supports remote operation and alarm annunciation in propulsion and auxiliary systems.

-

Industrial Manufacturing – Integrates with plant automation systems for machine and process monitoring.

-

Hospitals and Data Centers – Offers remote annunciation and control of backup power systems.

-

Renewable Energy Plants – Provides monitoring and annunciation for wind, hydro, and biomass installations.

Advantages

The Woodward 8446-1048 offers several key advantages for industrial and commercial operations:

-

Remote Accessibility – Provides operators with control and monitoring capabilities from a remote location.

-

Comprehensive Annunciation – Visual and audible alarms improve response times and system safety.

-

Robust Communication Options – Multiple ports and protocols ensure seamless integration with control systems.

-

Event Logging – Stores alarms and operational events for troubleshooting and performance analysis.

-

Rugged Design – Built to withstand industrial and marine environments.

-

User-Friendly Operation – Simple keypad and clear display reduce operator training requirements.

-

Safety-Oriented – Alarm acknowledgement features improve operational discipline.

-

Flexible Integration – Compatible with a wide range of Woodward controllers and third-party systems.

Frequently Asked Questions (FAQ)

-

Which communication protocols are supported by the 8446-1048?

It supports Modbus TCP/IP, Modbus RTU, and CANbus.

-

Can the panel issue remote start and stop commands?

Yes, it provides full remote control for start/stop and mode switching.

-

How are alarms annunciated on the panel?

Through both visual indicators on the display and audible signals.

-

What is the nominal power supply requirement?

The panel operates on a 24 VDC nominal input.

-

Does the panel support alarm acknowledgement?

Yes, operators can acknowledge and reset alarms directly from the panel.

-

Can it store historical event data?

Yes, it has non-volatile memory for alarm and event logging.

-

Is it compatible with marine-certified systems?

Yes, it carries marine approvals for shipboard applications.

-

What diagnostic features are available?

Built-in self-tests, error codes, and system health reporting.

-

Can it integrate into redundant control systems?

Yes, it supports integration into redundant architectures.

-

How is operator input managed?

Through a keypad and dedicated function buttons on the front panel.

Woodward 8446-1048 Remote Control And Annunciation Panel

Manufacturer:Woodward

Product Number:8446-1048

Product Type:Remote Control And Annunciation Panel

Origin:USA

Dimensions:282 x 217 x 67 mm

Weight:1.3 kg

Views:4

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Woodward 8446-1048 Remote Control and Annunciation Panel is an advanced operator interface designed to provide remote monitoring, control, and annunciation functions for engine, turbine, and generator management systems. It allows operators to access real-time system data, respond to alarms, and issue commands without being physically present at the primary controller.

This panel is built with rugged industrial-grade components to ensure durability in harsh environments such as power generation facilities, marine applications, oil and gas plants, and industrial automation systems. By combining remote control capability with detailed annunciation, it improves operational efficiency, enhances safety, and provides operators with situational awareness at all times.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 8446-1048 |

| Product Type | Remote Control and Annunciation Panel |

| Display | High-resolution LCD with status indicators |

| Control Features | Start/stop commands, mode switching, alarm acknowledgement |

| Annunciation Functions | Visual and audible alarm indication |

| Communication Ports | RS-232, RS-485, Ethernet |

| Supported Protocols | Modbus TCP/IP, Modbus RTU, CANbus |

| Input Methods | Keypad and function buttons |

| Processor | Industrial-grade embedded controller |

| Memory | Non-volatile storage for configuration and event logs |

| Power Supply | 24 VDC nominal |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Certifications | CE, UL, CSA, marine approvals |

| Dimensions | 282 x 217 x 67 mm |

| Weight | 1.3 kg |

| Mounting | Panel-mounted |

| Diagnostics | Built-in self-test, error codes, alarm history |

Applications

The 8446-1048 Remote Control and Annunciation Panel is suitable for a wide range of applications where remote access and monitoring are essential:

-

Power Generation Plants – Allows operators to control and monitor generators and auxiliary equipment.

-

Oil & Gas Facilities – Provides safe and efficient monitoring of critical process equipment.

-

Marine Applications – Supports remote operation and alarm annunciation in propulsion and auxiliary systems.

-

Industrial Manufacturing – Integrates with plant automation systems for machine and process monitoring.

-

Hospitals and Data Centers – Offers remote annunciation and control of backup power systems.

-

Renewable Energy Plants – Provides monitoring and annunciation for wind, hydro, and biomass installations.

Advantages

The Woodward 8446-1048 offers several key advantages for industrial and commercial operations:

-

Remote Accessibility – Provides operators with control and monitoring capabilities from a remote location.

-

Comprehensive Annunciation – Visual and audible alarms improve response times and system safety.

-

Robust Communication Options – Multiple ports and protocols ensure seamless integration with control systems.

-

Event Logging – Stores alarms and operational events for troubleshooting and performance analysis.

-

Rugged Design – Built to withstand industrial and marine environments.

-

User-Friendly Operation – Simple keypad and clear display reduce operator training requirements.

-

Safety-Oriented – Alarm acknowledgement features improve operational discipline.

-

Flexible Integration – Compatible with a wide range of Woodward controllers and third-party systems.

Frequently Asked Questions (FAQ)

-

Which communication protocols are supported by the 8446-1048?

It supports Modbus TCP/IP, Modbus RTU, and CANbus.

-

Can the panel issue remote start and stop commands?

Yes, it provides full remote control for start/stop and mode switching.

-

How are alarms annunciated on the panel?

Through both visual indicators on the display and audible signals.

-

What is the nominal power supply requirement?

The panel operates on a 24 VDC nominal input.

-

Does the panel support alarm acknowledgement?

Yes, operators can acknowledge and reset alarms directly from the panel.

-

Can it store historical event data?

Yes, it has non-volatile memory for alarm and event logging.

-

Is it compatible with marine-certified systems?

Yes, it carries marine approvals for shipboard applications.

-

What diagnostic features are available?

Built-in self-tests, error codes, and system health reporting.

-

Can it integrate into redundant control systems?

Yes, it supports integration into redundant architectures.

-

How is operator input managed?

Through a keypad and dedicated function buttons on the front panel.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...