Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

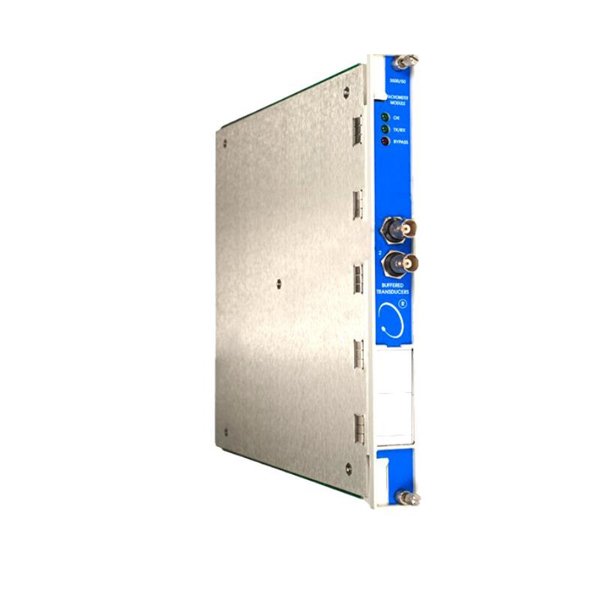

Bently Nevada 3500/50 134938-01 Speed Sensor Module

Manufacturer:Bently Nevada

Product Number:3500/50 134938-01

Product Type:Speed Sensor Module

Origin:USA

Dimensions:241.3 x 24.4 x 241.8mm

Weight:0.82kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/50 134938-01 Speed Sensor Module is a key component in the 3500 Series machinery protection and condition monitoring systems. Designed for precision and reliability, this module is primarily used to measure and monitor the rotational speed of critical rotating equipment in industrial environments. By providing real-time data on the speed of machinery, the module helps detect issues such as imbalance, wear, or potential failure before they lead to catastrophic breakdowns.

The 3500/50 Speed Sensor Module is widely used in industries such as power generation, oil and gas, and manufacturing, where accurate monitoring of rotating equipment is crucial for ensuring continuous operations and minimizing downtime. The module is designed for use in hazardous environments, where robust performance and reliability are essential. It is fully integrated into the Bently Nevada 3500 System, providing seamless communication and data transmission to the control system.

Product Parameters

The table below provides the key specifications of the Bently Nevada 3500/50 134938-01 Speed Sensor Module:

| Parameter | Value |

|---|---|

| Model | 3500/50 134938-01 |

| Dimensions (L x W x H) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.82 kg |

| Power Supply | 24 V DC |

| Signal Input | Tachometer Signal Input |

| Operating Temperature | -40°C to 85°C |

| Mounting Type | Rack Mount |

| Communication Interface | Bently Nevada 3500 System Integration |

| Data Update Rate | 500 ms |

| Signal Compatibility | Compatible with rotating machinery, sensors |

| Speed Measurement Range | 0 to 10,000 RPM |

| Maximum Input Voltage | 30 V DC |

Product Applications

The 3500/50 Speed Sensor Module is specifically designed for applications in industries that require continuous monitoring of rotating equipment. Key applications include:

-

Power Generation: Used in power plants to monitor the speed of turbines, generators, and other critical rotating machinery to prevent failure and ensure optimal performance.

-

Oil and Gas: In oil rigs and refineries, the module monitors the speed of compressors, pumps, and motors, alerting operators to potential issues that could affect production or safety.

-

Mining and Manufacturing: Critical in industries where machinery, such as crushers and conveyor belts, need constant speed monitoring to avoid breakdowns and maintain productivity.

-

Water Treatment: The module can be employed in water treatment plants for monitoring pumps and motors, ensuring smooth and uninterrupted operation.

-

Marine and Offshore Applications: In marine vessels and offshore platforms, it tracks the rotational speed of engines and other essential equipment.

-

Heavy Industry: For large-scale industrial operations, including steel production and cement manufacturing, where heavy-duty machinery is crucial to the overall process flow.

-

Predictive Maintenance: The module plays a critical role in predictive maintenance systems by providing valuable speed data that helps predict when a part might fail or require maintenance.

Product Advantages

The 3500/50 Speed Sensor Module offers numerous advantages that make it an essential tool for any industrial system where rotating equipment is involved:

-

Real-Time Data: Provides real-time speed data, allowing operators to monitor equipment and take proactive measures to prevent potential failures.

-

Wide Speed Range: With a measurement range of 0 to 10,000 RPM, the module is versatile and can be used for a wide variety of machinery.

-

High Data Accuracy: Ensures high accuracy in speed measurement, which is critical for detecting early signs of equipment wear or malfunction.

-

Durability in Harsh Environments: Designed for tough industrial environments, the module operates effectively in temperatures ranging from -40°C to 85°C, making it suitable for use in extreme conditions.

-

Predictive Maintenance Capabilities: By continually monitoring speed, the module helps identify issues before they lead to costly failures, supporting a predictive maintenance strategy.

-

Ease of Integration: Seamlessly integrates with the Bently Nevada 3500 monitoring system, ensuring that the data is readily available for analysis and decision-making.

-

Long-Lasting Reliability: Known for its robust design, the module offers reliable performance over a long lifespan, reducing the need for frequent replacements.

-

Compact and Lightweight: With dimensions of 241.3 x 24.4 x 241.8 mm and a weight of 0.82 kg, it is compact enough for easy installation in limited spaces within control panels or systems.

-

Enhanced Signal Processing: The module features advanced signal processing technology that ensures stable performance even in environments with electromagnetic interference.

-

Cost-Effective Solution: By preventing unexpected equipment failures and downtime, the 3500/50 Speed Sensor Module helps reduce long-term operational costs.

Frequently Asked Questions (FAQ)

-

What is the function of the Bently Nevada 3500/50 Speed Sensor Module?

-

The module is designed to measure and monitor the rotational speed of critical machinery, ensuring optimal performance and preventing equipment failures.

-

-

What is the speed measurement range of the 3500/50 module?

-

The module has a speed measurement range from 0 to 10,000 RPM.

-

-

What is the operating temperature range for this module?

-

The module operates within a temperature range of -40°C to 85°C.

-

-

Can the 3500/50 module be used in hazardous environments?

-

Yes, the module is designed for industrial environments, including those with harsh conditions and extreme temperatures.

-

-

How does the module integrate with the Bently Nevada system?

-

The 3500/50 seamlessly integrates with the Bently Nevada 3500 monitoring system, allowing easy communication and data sharing.

-

-

What is the power supply requirement for the 3500/50?

-

The module requires a 24 V DC power supply.

-

-

How does the 3500/50 help with predictive maintenance?

-

The module continuously monitors the speed of machinery, allowing early detection of issues that may lead to equipment failure, thus enabling predictive maintenance strategies.

-

-

What types of equipment can the 3500/50 monitor?

-

The module can monitor any rotating machinery, such as turbines, motors, compressors, and pumps.

-

-

What is the weight of the Bently Nevada 3500/50 module?

-

The module weighs 0.82 kg.

-

-

What industries benefit from using the 3500/50 module?

-

Industries such as power generation, oil and gas, manufacturing, water treatment, and heavy industry benefit from using the module for machinery monitoring.

-

Bently Nevada 3500/50 134938-01 Speed Sensor Module

Manufacturer:Bently Nevada

Product Number:3500/50 134938-01

Product Type:Speed Sensor Module

Origin:USA

Dimensions:241.3 x 24.4 x 241.8mm

Weight:0.82kg

Views:39

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/50 134938-01 Speed Sensor Module is a key component in the 3500 Series machinery protection and condition monitoring systems. Designed for precision and reliability, this module is primarily used to measure and monitor the rotational speed of critical rotating equipment in industrial environments. By providing real-time data on the speed of machinery, the module helps detect issues such as imbalance, wear, or potential failure before they lead to catastrophic breakdowns.

The 3500/50 Speed Sensor Module is widely used in industries such as power generation, oil and gas, and manufacturing, where accurate monitoring of rotating equipment is crucial for ensuring continuous operations and minimizing downtime. The module is designed for use in hazardous environments, where robust performance and reliability are essential. It is fully integrated into the Bently Nevada 3500 System, providing seamless communication and data transmission to the control system.

Product Parameters

The table below provides the key specifications of the Bently Nevada 3500/50 134938-01 Speed Sensor Module:

| Parameter | Value |

|---|---|

| Model | 3500/50 134938-01 |

| Dimensions (L x W x H) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.82 kg |

| Power Supply | 24 V DC |

| Signal Input | Tachometer Signal Input |

| Operating Temperature | -40°C to 85°C |

| Mounting Type | Rack Mount |

| Communication Interface | Bently Nevada 3500 System Integration |

| Data Update Rate | 500 ms |

| Signal Compatibility | Compatible with rotating machinery, sensors |

| Speed Measurement Range | 0 to 10,000 RPM |

| Maximum Input Voltage | 30 V DC |

Product Applications

The 3500/50 Speed Sensor Module is specifically designed for applications in industries that require continuous monitoring of rotating equipment. Key applications include:

-

Power Generation: Used in power plants to monitor the speed of turbines, generators, and other critical rotating machinery to prevent failure and ensure optimal performance.

-

Oil and Gas: In oil rigs and refineries, the module monitors the speed of compressors, pumps, and motors, alerting operators to potential issues that could affect production or safety.

-

Mining and Manufacturing: Critical in industries where machinery, such as crushers and conveyor belts, need constant speed monitoring to avoid breakdowns and maintain productivity.

-

Water Treatment: The module can be employed in water treatment plants for monitoring pumps and motors, ensuring smooth and uninterrupted operation.

-

Marine and Offshore Applications: In marine vessels and offshore platforms, it tracks the rotational speed of engines and other essential equipment.

-

Heavy Industry: For large-scale industrial operations, including steel production and cement manufacturing, where heavy-duty machinery is crucial to the overall process flow.

-

Predictive Maintenance: The module plays a critical role in predictive maintenance systems by providing valuable speed data that helps predict when a part might fail or require maintenance.

Product Advantages

The 3500/50 Speed Sensor Module offers numerous advantages that make it an essential tool for any industrial system where rotating equipment is involved:

-

Real-Time Data: Provides real-time speed data, allowing operators to monitor equipment and take proactive measures to prevent potential failures.

-

Wide Speed Range: With a measurement range of 0 to 10,000 RPM, the module is versatile and can be used for a wide variety of machinery.

-

High Data Accuracy: Ensures high accuracy in speed measurement, which is critical for detecting early signs of equipment wear or malfunction.

-

Durability in Harsh Environments: Designed for tough industrial environments, the module operates effectively in temperatures ranging from -40°C to 85°C, making it suitable for use in extreme conditions.

-

Predictive Maintenance Capabilities: By continually monitoring speed, the module helps identify issues before they lead to costly failures, supporting a predictive maintenance strategy.

-

Ease of Integration: Seamlessly integrates with the Bently Nevada 3500 monitoring system, ensuring that the data is readily available for analysis and decision-making.

-

Long-Lasting Reliability: Known for its robust design, the module offers reliable performance over a long lifespan, reducing the need for frequent replacements.

-

Compact and Lightweight: With dimensions of 241.3 x 24.4 x 241.8 mm and a weight of 0.82 kg, it is compact enough for easy installation in limited spaces within control panels or systems.

-

Enhanced Signal Processing: The module features advanced signal processing technology that ensures stable performance even in environments with electromagnetic interference.

-

Cost-Effective Solution: By preventing unexpected equipment failures and downtime, the 3500/50 Speed Sensor Module helps reduce long-term operational costs.

Frequently Asked Questions (FAQ)

-

What is the function of the Bently Nevada 3500/50 Speed Sensor Module?

-

The module is designed to measure and monitor the rotational speed of critical machinery, ensuring optimal performance and preventing equipment failures.

-

-

What is the speed measurement range of the 3500/50 module?

-

The module has a speed measurement range from 0 to 10,000 RPM.

-

-

What is the operating temperature range for this module?

-

The module operates within a temperature range of -40°C to 85°C.

-

-

Can the 3500/50 module be used in hazardous environments?

-

Yes, the module is designed for industrial environments, including those with harsh conditions and extreme temperatures.

-

-

How does the module integrate with the Bently Nevada system?

-

The 3500/50 seamlessly integrates with the Bently Nevada 3500 monitoring system, allowing easy communication and data sharing.

-

-

What is the power supply requirement for the 3500/50?

-

The module requires a 24 V DC power supply.

-

-

How does the 3500/50 help with predictive maintenance?

-

The module continuously monitors the speed of machinery, allowing early detection of issues that may lead to equipment failure, thus enabling predictive maintenance strategies.

-

-

What types of equipment can the 3500/50 monitor?

-

The module can monitor any rotating machinery, such as turbines, motors, compressors, and pumps.

-

-

What is the weight of the Bently Nevada 3500/50 module?

-

The module weighs 0.82 kg.

-

-

What industries benefit from using the 3500/50 module?

-

Industries such as power generation, oil and gas, manufacturing, water treatment, and heavy industry benefit from using the module for machinery monitoring.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...