Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

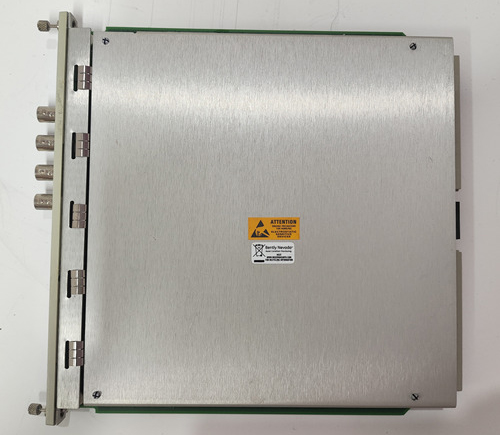

Bently Nevada 3500/25-01-03-00 135473-01 Transient Data Interface Module

Manufacturer:Bently Nevada

Product Number:3500/25-01-03-00 135473-01

Product Type:Transient Data Interface Module

Origin:USA

Dimensions:241.3 x 24.4 x 103.1 mm

Weight:0.46 kg

Views:98

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/25-01-03-00 (Part Number: 135473-01) is a high-performance Transient Data Interface (TDI) Module, designed to operate as the central processor of the 3500 Machinery Protection System. It combines the functionality of a system controller with the capability to interface with GE’s System 1® software for condition monitoring and diagnostics.

This module is an essential component in the Bently Nevada 3500 Series, enabling comprehensive machinery protection and real-time data acquisition. It gathers and relays critical data to support predictive maintenance strategies and ensure the reliability of rotating machinery, including turbines, compressors, pumps, and generators in industrial applications.

Product Specifications

| Parameter | Details |

| Model | 3500/25-01-03-00 |

| Part Number | 135473-01 |

| Function | Transient Data Interface Module (TDI) |

| Communication Interface | System 1® Software via Ethernet (Static and Transient Data Support) |

| Power Consumption | 7.5 Watts (typical) |

| Input Voltage Range | Supplied via the 3500 rack (24 VDC nominal) |

| LED Indicators | OK, TX/RX, CONFIG, BUFFERED OUT, TX/RX SYNC |

| Ethernet Protocol Support | Modbus TCP/IP, Configurable for System 1® |

| Mounting Type | Front-slot plug-in for 3500 Series Rack |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 0% to 95% non-condensing |

| Dimensions | 241.3 x 24.4 x 103.1 mm |

| Weight | 0.46 kg |

| Certification | CE, CSA, ATEX, GOST, IECEx |

| Firmware Compatibility | Compatible with all 3500 Series rack modules and System 1 software |

Applications

-

Turbomachinery Monitoring: Steam turbines, gas turbines, compressors, and expanders.

-

Critical Machinery Protection: Applied in oil refineries, petrochemical plants, power generation facilities, and industrial manufacturing.

-

Condition Monitoring Gateway: Acts as a bridge between the 3500 system and System 1® software for diagnostics and predictive maintenance.

-

Real-Time Data Collection: Enables time-synchronized collection of static and transient data for in-depth machinery analysis.

-

Fault Investigation: Captures high-speed data streams during machinery trips and faults for detailed root-cause analysis.

Advantages

-

Integrated Functionality: Combines system controller and communication gateway in a single module.

-

Advanced Diagnostics: Enables in-depth diagnostics via System 1® for proactive maintenance.

-

High Compatibility: Fully compatible with all 3500 series modules and System 1® platform.

-

Simplified Setup: Automatically recognizes module configurations and supports hot-swapping.

-

Redundant Capability: Supports dual TDI installation for high-availability systems.

-

Global Certification: Certified for use in hazardous environments and across international industries.

-

Modbus Support: Facilitates communication with third-party systems via Modbus TCP/IP.

-

Time-Synchronized Data: Ensures consistent and reliable data capture across multiple channels.

Frequently Asked Questions (FAQ)

-

What is the primary function of the 3500/25 TDI module?

The TDI acts as the system controller and data interface for System 1® software in the Bently Nevada 3500 system.

-

Is the 3500/25 module compatible with other 3500 rack modules?

Yes, it is fully compatible with all 3500 series monitoring modules.

-

Does this module support transient data recording?

Yes, it supports both static and transient data for comprehensive condition monitoring.

-

Can it be used in redundant configurations?

Absolutely. The module supports dual TDI configurations for redundancy and reliability.

-

What is the communication protocol used by the TDI?

It communicates via Ethernet using Modbus TCP/IP and interfaces with System 1® software.

-

What kind of data can System 1® access through the TDI?

System 1® can access static data, transient data, alarms, and configuration settings.

-

Is the 3500/25 suitable for use in hazardous locations?

Yes, the module is certified for use in hazardous areas with ATEX, CSA, and IECEx approvals.

-

What firmware versions are supported by the 3500/25 TDI?

The TDI supports the latest firmware releases compatible with the 3500 system.

-

How is power supplied to the TDI module?

The module receives power through the 3500 rack’s power distribution system.

-

What happens if the TDI module fails?

In redundant configurations, the secondary TDI takes over seamlessly; in single setups, the system will alarm, but protection continues independently.

Bently Nevada 3500/25-01-03-00 135473-01 Transient Data Interface Module

Manufacturer:Bently Nevada

Product Number:3500/25-01-03-00 135473-01

Product Type:Transient Data Interface Module

Origin:USA

Dimensions:241.3 x 24.4 x 103.1 mm

Weight:0.46 kg

Views:98

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/25-01-03-00 (Part Number: 135473-01) is a high-performance Transient Data Interface (TDI) Module, designed to operate as the central processor of the 3500 Machinery Protection System. It combines the functionality of a system controller with the capability to interface with GE’s System 1® software for condition monitoring and diagnostics.

This module is an essential component in the Bently Nevada 3500 Series, enabling comprehensive machinery protection and real-time data acquisition. It gathers and relays critical data to support predictive maintenance strategies and ensure the reliability of rotating machinery, including turbines, compressors, pumps, and generators in industrial applications.

Product Specifications

| Parameter | Details |

| Model | 3500/25-01-03-00 |

| Part Number | 135473-01 |

| Function | Transient Data Interface Module (TDI) |

| Communication Interface | System 1® Software via Ethernet (Static and Transient Data Support) |

| Power Consumption | 7.5 Watts (typical) |

| Input Voltage Range | Supplied via the 3500 rack (24 VDC nominal) |

| LED Indicators | OK, TX/RX, CONFIG, BUFFERED OUT, TX/RX SYNC |

| Ethernet Protocol Support | Modbus TCP/IP, Configurable for System 1® |

| Mounting Type | Front-slot plug-in for 3500 Series Rack |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 0% to 95% non-condensing |

| Dimensions | 241.3 x 24.4 x 103.1 mm |

| Weight | 0.46 kg |

| Certification | CE, CSA, ATEX, GOST, IECEx |

| Firmware Compatibility | Compatible with all 3500 Series rack modules and System 1 software |

Applications

-

Turbomachinery Monitoring: Steam turbines, gas turbines, compressors, and expanders.

-

Critical Machinery Protection: Applied in oil refineries, petrochemical plants, power generation facilities, and industrial manufacturing.

-

Condition Monitoring Gateway: Acts as a bridge between the 3500 system and System 1® software for diagnostics and predictive maintenance.

-

Real-Time Data Collection: Enables time-synchronized collection of static and transient data for in-depth machinery analysis.

-

Fault Investigation: Captures high-speed data streams during machinery trips and faults for detailed root-cause analysis.

Advantages

-

Integrated Functionality: Combines system controller and communication gateway in a single module.

-

Advanced Diagnostics: Enables in-depth diagnostics via System 1® for proactive maintenance.

-

High Compatibility: Fully compatible with all 3500 series modules and System 1® platform.

-

Simplified Setup: Automatically recognizes module configurations and supports hot-swapping.

-

Redundant Capability: Supports dual TDI installation for high-availability systems.

-

Global Certification: Certified for use in hazardous environments and across international industries.

-

Modbus Support: Facilitates communication with third-party systems via Modbus TCP/IP.

-

Time-Synchronized Data: Ensures consistent and reliable data capture across multiple channels.

Frequently Asked Questions (FAQ)

-

What is the primary function of the 3500/25 TDI module?

The TDI acts as the system controller and data interface for System 1® software in the Bently Nevada 3500 system.

-

Is the 3500/25 module compatible with other 3500 rack modules?

Yes, it is fully compatible with all 3500 series monitoring modules.

-

Does this module support transient data recording?

Yes, it supports both static and transient data for comprehensive condition monitoring.

-

Can it be used in redundant configurations?

Absolutely. The module supports dual TDI configurations for redundancy and reliability.

-

What is the communication protocol used by the TDI?

It communicates via Ethernet using Modbus TCP/IP and interfaces with System 1® software.

-

What kind of data can System 1® access through the TDI?

System 1® can access static data, transient data, alarms, and configuration settings.

-

Is the 3500/25 suitable for use in hazardous locations?

Yes, the module is certified for use in hazardous areas with ATEX, CSA, and IECEx approvals.

-

What firmware versions are supported by the 3500/25 TDI?

The TDI supports the latest firmware releases compatible with the 3500 system.

-

How is power supplied to the TDI module?

The module receives power through the 3500 rack’s power distribution system.

-

What happens if the TDI module fails?

In redundant configurations, the secondary TDI takes over seamlessly; in single setups, the system will alarm, but protection continues independently.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...