Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

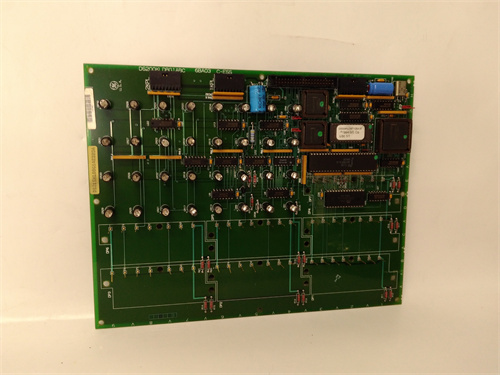

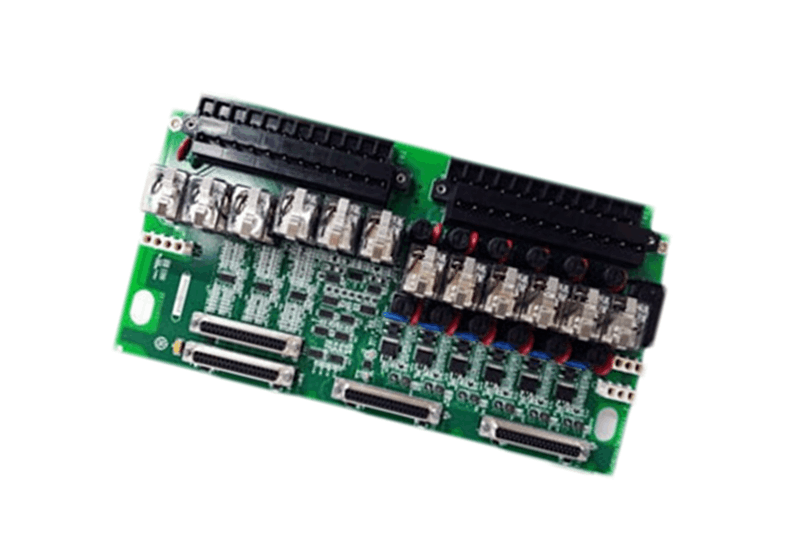

GE Fanuc IC693MDL730 Module

Number of channels: 8

Voltage ranges: bipolar (-10 to +10 volts), unipolar (0 to +10 volts)

Current ranges: 0 to 20 milliamps, 4 to 20 milliamps

Digital-analog conversion: 15 to 16 bits

Update rate: 8 milliseconds per channel

Open wire fault reporting: Yes

Known last state on power loss: Yes

External power supply: 24 VDC

Output channels: single-ended

Factory adjusted to .625 μA

Product Description

The GE Fanuc IC693MDL730 module is a brand-new input module that is capable of handling 16 input points. It has a long service life and is highly reliable, making it perfect for a range of industrial applications. This module is compatible with a wide range of GE Fanuc PLC systems and is easy to install and configure. Additionally, it is designed to operate in harsh environments, making it ideal for use in demanding industrial settings.

Introduction

The GE Fanuc IC693MDL730 is a 12/24VDC 2A 16-point positive/negative logic input module that is part of the GE Fanuc 90-30 Series PLC system. It is designed to monitor the status of digital input devices and provide high-density digital input capabilities for industrial automation applications.

Features

The GE Fanuc IC693MDL730 module has several features, including:

- 16 input points

- 12/24VDC input voltage

- 2A input current per point

- Positive/negative logic selectable per point

- High-density module with low power consumption

- LED indicators for status and diagnosis

- User-configurable fault detection and alarm features

Applications

The GE Fanuc IC693MDL730 module can be used in a variety of industrial automation applications, such as:

- Machine control

- Process control

- Material handling

- Packaging

- Robotics

- Test and measurement

- And more.

Installation

To install the GE Fanuc IC693MDL730 module, follow these steps:

- Turn off power to the PLC system.

- Select an available slot in the I/O rack.

- Remove the protective cover from the slot.

- Slide the module into the slot until it clicks into place.

- Use the screws provided to secure the module to the rack.

- Reattach the protective cover.

Configuration

The GE Fanuc IC693MDL730 module can be configured using the GE Fanuc programming software. The configuration process involves assigning an address to the module, setting input modes, and enabling fault detection and alarm features.

FAQs

Q: Can the GE Fanuc IC693MDL730 module work with both positive and negative logic signals?

A: Yes, the GE Fanuc IC693MDL730 module can work with both positive and negative logic signals. Each point can be configured for either positive or negative logic.

Q: What is the input voltage range of the GE Fanuc IC693MDL730 module?

A: The GE Fanuc IC693MDL730 module has an input voltage range of 12/24VDC.

Q: How many input points does the GE Fanuc IC693MDL730 module have?

A: The GE Fanuc IC693MDL730 module has 16 input points.

Q: What is the input current per point of the GE Fanuc IC693MDL730 module?

A: The GE Fanuc IC693MDL730 module has an input current of 2A per point.

Q: What are the LED indicators on the GE Fanuc IC693MDL730 module for?

A: The LED indicators on the GE Fanuc IC693MDL730 module are used to display the status of each input point and diagnose faults.

Q: What types of applications can the GE Fanuc IC693MDL730 module be used in?

A: The GE Fanuc IC693MDL730 module can be used in a variety of industrial automation applications, such as machine control, process control, material handling, and more.

GE Fanuc IC693MDL730 Module

Number of channels: 8

Voltage ranges: bipolar (-10 to +10 volts), unipolar (0 to +10 volts)

Current ranges: 0 to 20 milliamps, 4 to 20 milliamps

Digital-analog conversion: 15 to 16 bits

Update rate: 8 milliseconds per channel

Open wire fault reporting: Yes

Known last state on power loss: Yes

External power supply: 24 VDC

Output channels: single-ended

Factory adjusted to .625 μA

Product Description

The GE Fanuc IC693MDL730 module is a brand-new input module that is capable of handling 16 input points. It has a long service life and is highly reliable, making it perfect for a range of industrial applications. This module is compatible with a wide range of GE Fanuc PLC systems and is easy to install and configure. Additionally, it is designed to operate in harsh environments, making it ideal for use in demanding industrial settings.

Introduction

The GE Fanuc IC693MDL730 is a 12/24VDC 2A 16-point positive/negative logic input module that is part of the GE Fanuc 90-30 Series PLC system. It is designed to monitor the status of digital input devices and provide high-density digital input capabilities for industrial automation applications.

Features

The GE Fanuc IC693MDL730 module has several features, including:

- 16 input points

- 12/24VDC input voltage

- 2A input current per point

- Positive/negative logic selectable per point

- High-density module with low power consumption

- LED indicators for status and diagnosis

- User-configurable fault detection and alarm features

Applications

The GE Fanuc IC693MDL730 module can be used in a variety of industrial automation applications, such as:

- Machine control

- Process control

- Material handling

- Packaging

- Robotics

- Test and measurement

- And more.

Installation

To install the GE Fanuc IC693MDL730 module, follow these steps:

- Turn off power to the PLC system.

- Select an available slot in the I/O rack.

- Remove the protective cover from the slot.

- Slide the module into the slot until it clicks into place.

- Use the screws provided to secure the module to the rack.

- Reattach the protective cover.

Configuration

The GE Fanuc IC693MDL730 module can be configured using the GE Fanuc programming software. The configuration process involves assigning an address to the module, setting input modes, and enabling fault detection and alarm features.

FAQs

Q: Can the GE Fanuc IC693MDL730 module work with both positive and negative logic signals?

A: Yes, the GE Fanuc IC693MDL730 module can work with both positive and negative logic signals. Each point can be configured for either positive or negative logic.

Q: What is the input voltage range of the GE Fanuc IC693MDL730 module?

A: The GE Fanuc IC693MDL730 module has an input voltage range of 12/24VDC.

Q: How many input points does the GE Fanuc IC693MDL730 module have?

A: The GE Fanuc IC693MDL730 module has 16 input points.

Q: What is the input current per point of the GE Fanuc IC693MDL730 module?

A: The GE Fanuc IC693MDL730 module has an input current of 2A per point.

Q: What are the LED indicators on the GE Fanuc IC693MDL730 module for?

A: The LED indicators on the GE Fanuc IC693MDL730 module are used to display the status of each input point and diagnose faults.

Q: What types of applications can the GE Fanuc IC693MDL730 module be used in?

A: The GE Fanuc IC693MDL730 module can be used in a variety of industrial automation applications, such as machine control, process control, material handling, and more.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...