Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

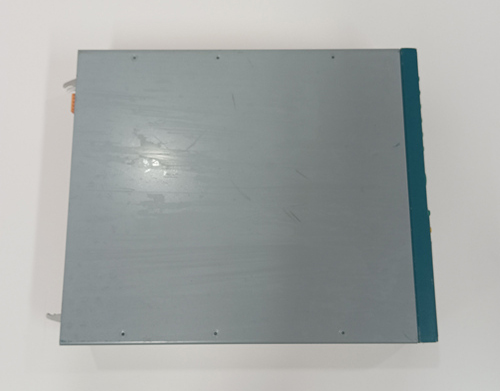

Bently Nevada 3300/47-XX-03-01-00 Differential Expansion Monitor

Brand:Bently Nevada

Model Number:3300/47-XX-03-01-00

Type:Differential Expansion Monitor

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:5.1 cm x 20.3 cm x 33.0 cm

Weight:1.4 kg

Price:USD59

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/47-XX-03-01-00 Differential Expansion Monitor measures and monitors the expansion or contraction of rotating machinery components. It is crucial for precise control of differential expansion in turbines, pumps, and compressors.

Key Features

- Measures Differential Expansion: Accurately gauges the difference in expansion between two points on a rotating machine.

- Wide Measurement Range: Accommodates various expansion ranges based on the model.

- High Accuracy: Delivers precise measurements with minimal error.

- Rugged Construction: Withstands harsh industrial environments.

- Easy Installation: Integrates seamlessly into existing monitoring systems.

Applications

- Turbines: Monitors differential expansion of turbine casings and rotors, preventing thermal stress and vibrations.

- Pumps: Measures the expansion of pump shafts and impellers, ensuring proper alignment and performance.

- Compressors: Tracks expansion of compressor cylinders and pistons, preventing overheating and mechanical failure.

- Other Rotating Machinery: Suitable for any application where differential expansion is a critical factor.

Benefits

- Improved Reliability: Detects excessive expansion early, preventing equipment failures and downtime.

- Enhanced Efficiency: Optimizes control of differential expansion, boosting overall machinery efficiency.

- Reduced Maintenance Costs: Regular monitoring identifies potential issues early, minimizing costly repairs.

Bently Nevada 3300/47-XX-03-01-00 Differential Expansion Monitor

Brand:Bently Nevada

Model Number:3300/47-XX-03-01-00

Type:Differential Expansion Monitor

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:5.1 cm x 20.3 cm x 33.0 cm

Weight:1.4 kg

Price:USD59

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/47-XX-03-01-00 Differential Expansion Monitor measures and monitors the expansion or contraction of rotating machinery components. It is crucial for precise control of differential expansion in turbines, pumps, and compressors.

Key Features

- Measures Differential Expansion: Accurately gauges the difference in expansion between two points on a rotating machine.

- Wide Measurement Range: Accommodates various expansion ranges based on the model.

- High Accuracy: Delivers precise measurements with minimal error.

- Rugged Construction: Withstands harsh industrial environments.

- Easy Installation: Integrates seamlessly into existing monitoring systems.

Applications

- Turbines: Monitors differential expansion of turbine casings and rotors, preventing thermal stress and vibrations.

- Pumps: Measures the expansion of pump shafts and impellers, ensuring proper alignment and performance.

- Compressors: Tracks expansion of compressor cylinders and pistons, preventing overheating and mechanical failure.

- Other Rotating Machinery: Suitable for any application where differential expansion is a critical factor.

Benefits

- Improved Reliability: Detects excessive expansion early, preventing equipment failures and downtime.

- Enhanced Efficiency: Optimizes control of differential expansion, boosting overall machinery efficiency.

- Reduced Maintenance Costs: Regular monitoring identifies potential issues early, minimizing costly repairs.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...