Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

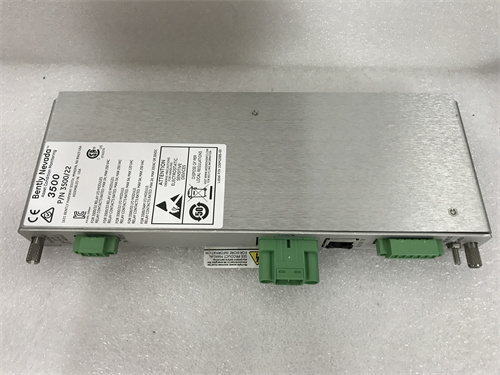

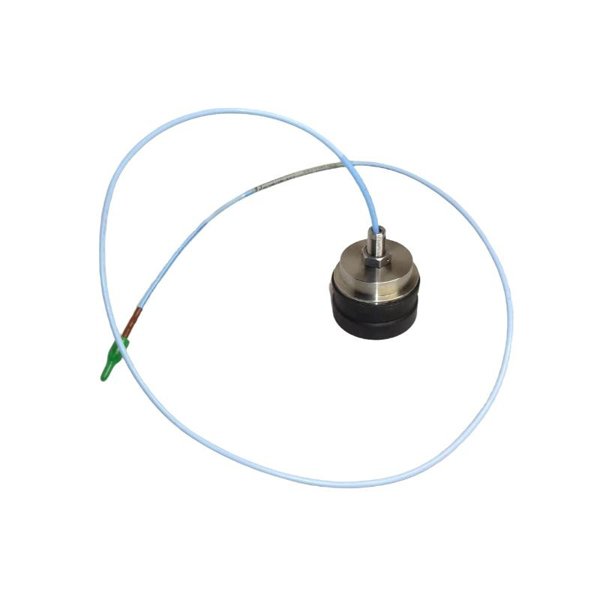

Bently Nevada 330876-03-10-01-00 3300 XL 50 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330876-03-10-01-00

Product Type:3300 XL 50 mm Proximity Probe

Origin:USA

Total Length:1 meter

Shipping Weight:3 kg

Views:9

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330876-03-10-01-00 3300 XL 50 mm Proximity Probe is a high-precision, non-contact sensor designed for monitoring shaft displacement and vibration in critical industrial machinery. Part of the 3300 XL series, this probe delivers accurate, high-fidelity measurements essential for condition monitoring and machinery protection systems. With a 50 mm probe tip, it is optimized for larger machinery applications such as turbines, compressors, and generators. The probe converts mechanical displacement into an electrical signal compatible with Bently Nevada Proximitor® sensors and monitoring systems, providing reliable early detection of misalignment, imbalance, or mechanical degradation.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 330876-03-10-01-00 |

| Probe Type | 3300 XL 50 mm Proximity Probe |

| Linear Range | 5–50 mm (depending on installation) |

| Sensitivity | 7.87 mV/µm nominal |

| Frequency Response | 0 Hz – 10 kHz (±3 dB) |

| Operating Temperature | –35 °C to +177 °C |

| Storage Temperature | –40 °C to +177 °C |

| Pressure Rating | Up to 2000 psi (137 bar) |

| Insulation Resistance | >10 MΩ @ 500 VDC |

| Cable Type | Factory-integrated, armored |

| Total Cable Length | 1.0 meter |

| Shipping Weight | 3 kg |

Applications

Large Turbines – Shaft displacement and vibration monitoring for steam, gas, and hydro turbines.

Compressors – Continuous monitoring of high-speed compressors to prevent bearing damage or misalignment.

Electric Generators – Rotor position tracking for generator protection and performance optimization.

Industrial Pumps – Shaft vibration monitoring in critical process applications.

Petrochemical Plants – Condition monitoring in high-pressure, high-temperature process equipment.

Heavy Industrial Equipment – Detects imbalance, rubs, or misalignment in large rotating machinery.

Advantages

High Accuracy – Provides precise linear measurement over a wide range with minimal thermal drift.

API 670 Compliance – Meets international standards for machinery protection and vibration monitoring.

Robust Design – Stainless steel construction and armored cable ensure durability in harsh industrial environments.

Wide Operating Range – Operates reliably under extreme temperatures, pressure, and vibration conditions.

Seamless System Integration – Fully compatible with 3300 XL Proximitor® sensors and monitoring systems.

Non-Contact Measurement – Reduces wear and maintenance while providing reliable continuous monitoring.

Easy Installation – Designed for rapid deployment in large machinery applications.

FAQ

What target material provides the most accurate measurement?

AISI 4140 or similar carbon steel is recommended for calibration and best accuracy.

How is electromagnetic interference minimized?

The probe uses a coaxial design with grounded shielding to reduce external electrical noise.

Can the probe operate in high-vibration environments?

Yes, it is designed to maintain stable measurements even under severe vibration.

What is the typical output impedance of the probe system?

Approximately 50 Ω when connected to the specified Proximitor sensor.

How does the probe compensate for temperature changes?

Internal materials and factory calibration minimize thermal drift across the operating temperature range.

Is this probe compatible with older Bently Nevada drivers?

It is recommended to use with 3300 XL or 3500 series Proximitor drivers for full performance.

What is the recommended gap voltage for optimal linearity?

Typically around –10 VDC at mid-gap position.

How does cable length affect signal quality?

The probe is calibrated for a total system length; any modification requires recalibration.

What protection does the probe provide against moisture ingress?

The assembly meets IP67 sealing when installed with proper hardware.

What is the maximum static pressure rating at the probe tip?

The probe tip can withstand pressures up to 2000 psi (137 bar).

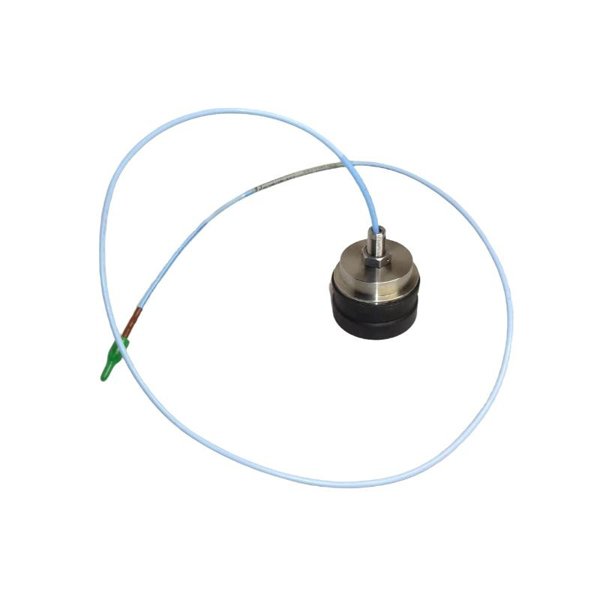

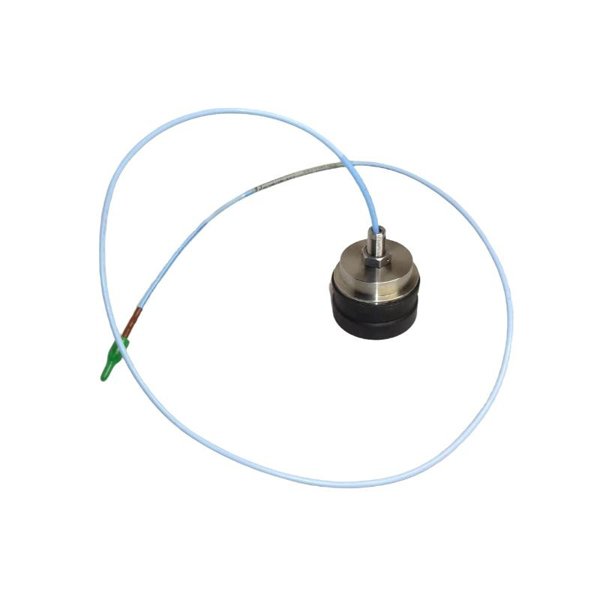

Bently Nevada 330876-03-10-01-00 3300 XL 50 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330876-03-10-01-00

Product Type:3300 XL 50 mm Proximity Probe

Origin:USA

Total Length:1 meter

Shipping Weight:3 kg

Views:9

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330876-03-10-01-00 3300 XL 50 mm Proximity Probe is a high-precision, non-contact sensor designed for monitoring shaft displacement and vibration in critical industrial machinery. Part of the 3300 XL series, this probe delivers accurate, high-fidelity measurements essential for condition monitoring and machinery protection systems. With a 50 mm probe tip, it is optimized for larger machinery applications such as turbines, compressors, and generators. The probe converts mechanical displacement into an electrical signal compatible with Bently Nevada Proximitor® sensors and monitoring systems, providing reliable early detection of misalignment, imbalance, or mechanical degradation.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 330876-03-10-01-00 |

| Probe Type | 3300 XL 50 mm Proximity Probe |

| Linear Range | 5–50 mm (depending on installation) |

| Sensitivity | 7.87 mV/µm nominal |

| Frequency Response | 0 Hz – 10 kHz (±3 dB) |

| Operating Temperature | –35 °C to +177 °C |

| Storage Temperature | –40 °C to +177 °C |

| Pressure Rating | Up to 2000 psi (137 bar) |

| Insulation Resistance | >10 MΩ @ 500 VDC |

| Cable Type | Factory-integrated, armored |

| Total Cable Length | 1.0 meter |

| Shipping Weight | 3 kg |

Applications

Large Turbines – Shaft displacement and vibration monitoring for steam, gas, and hydro turbines.

Compressors – Continuous monitoring of high-speed compressors to prevent bearing damage or misalignment.

Electric Generators – Rotor position tracking for generator protection and performance optimization.

Industrial Pumps – Shaft vibration monitoring in critical process applications.

Petrochemical Plants – Condition monitoring in high-pressure, high-temperature process equipment.

Heavy Industrial Equipment – Detects imbalance, rubs, or misalignment in large rotating machinery.

Advantages

High Accuracy – Provides precise linear measurement over a wide range with minimal thermal drift.

API 670 Compliance – Meets international standards for machinery protection and vibration monitoring.

Robust Design – Stainless steel construction and armored cable ensure durability in harsh industrial environments.

Wide Operating Range – Operates reliably under extreme temperatures, pressure, and vibration conditions.

Seamless System Integration – Fully compatible with 3300 XL Proximitor® sensors and monitoring systems.

Non-Contact Measurement – Reduces wear and maintenance while providing reliable continuous monitoring.

Easy Installation – Designed for rapid deployment in large machinery applications.

FAQ

What target material provides the most accurate measurement?

AISI 4140 or similar carbon steel is recommended for calibration and best accuracy.

How is electromagnetic interference minimized?

The probe uses a coaxial design with grounded shielding to reduce external electrical noise.

Can the probe operate in high-vibration environments?

Yes, it is designed to maintain stable measurements even under severe vibration.

What is the typical output impedance of the probe system?

Approximately 50 Ω when connected to the specified Proximitor sensor.

How does the probe compensate for temperature changes?

Internal materials and factory calibration minimize thermal drift across the operating temperature range.

Is this probe compatible with older Bently Nevada drivers?

It is recommended to use with 3300 XL or 3500 series Proximitor drivers for full performance.

What is the recommended gap voltage for optimal linearity?

Typically around –10 VDC at mid-gap position.

How does cable length affect signal quality?

The probe is calibrated for a total system length; any modification requires recalibration.

What protection does the probe provide against moisture ingress?

The assembly meets IP67 sealing when installed with proper hardware.

What is the maximum static pressure rating at the probe tip?

The probe tip can withstand pressures up to 2000 psi (137 bar).

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...