Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

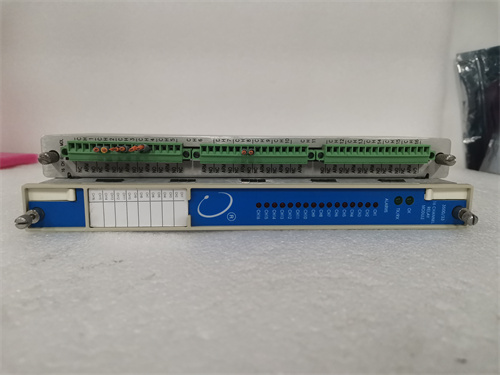

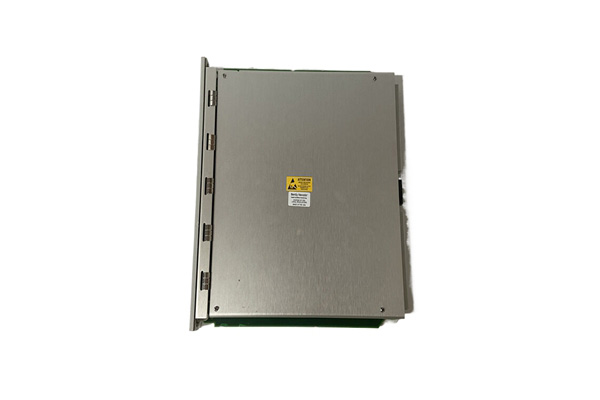

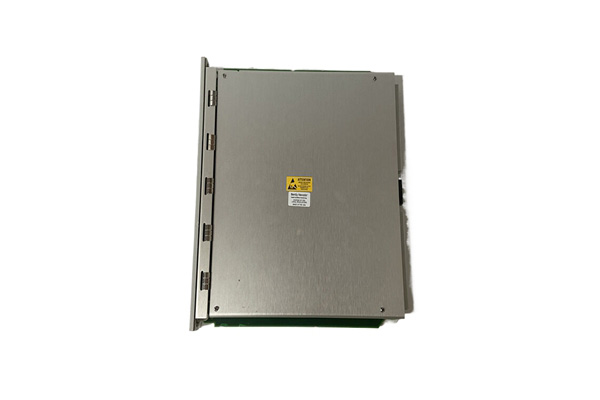

Bently Nevada 3500/42M 176449-02 high-precision Monitoring Module

Module Number:3500/42M 176449-02

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The BENTLY 3500/42M 176449-02 module is a high-performance and high-precision monitoring module widely used in industrial automation systems, especially in equipment operation and maintenance in industries such as energy, oil and natural gas, and chemical engineering. The following is a detailed introduction to this module.

Module Overview

The BENTLY 3500/42M 176449-02 module is designed specifically for monitoring the vibration and displacement of mechanical equipment. It can monitor the vibration level and displacement changes of rotating mechanical equipment in real time, help evaluate the operating status of the equipment, detect abnormal situations in a timely manner, and make adjustments to ensure the reliability and safety of the equipment.

Main features

High precision measurement:

This module provides up to 24 bit resolution and low noise levels, enabling accurate analog signal measurement.

Has excellent linearity and low drift performance, ensuring accurate measurement results over a wide dynamic range.

Multi channel monitoring:

As a configurable 4-channel monitoring module, it can simultaneously monitor multiple parameters such as radial vibration, axial displacement, eccentricity, REBAM, and differential expansion, improving the efficiency of testing and measurement.

Flexible input range:

Support multiple adjustable input ranges to adapt to the amplitude requirements of different signal sources, enhancing measurement flexibility and accuracy.

Built in calibration function:

Equipped with built-in automatic calibration function, it can calibrate each channel during the measurement process, improving measurement accuracy and reliability.

In addition, it also supports standard calibration procedures to further ensure the consistency and accuracy of measurement results.

High speed data transmission:

Adopting PXIE bus interface, it has high-speed data transmission capability and can quickly transmit collected data to the computer for processing and analysis.

Powerful software support:

Tightly integrated with NI’s LabVIEW and other software tools, it provides rich functionality and easy-to-use programming interfaces, making it convenient for users to perform data collection, real-time monitoring, automated testing, and remote control operations.

Application field

The BENTLY 3500/42M 176449-02 module plays an important role in multiple industrial fields, including but not limited to:

Energy industry: used in power plants, power plants, and other energy facilities to monitor the bearing status and vibration levels of rotating equipment such as generators, turbines, and wind turbines.

The oil and gas industry: used to monitor the vibration levels of rotating equipment such as pumps and compressors in oil drilling, refineries, and natural gas processing facilities.

Chemical industry: used to monitor the vibration and displacement of rotating equipment such as mixers, centrifuges, and pumps in the chemical production process.

Summary

The BENTLY 3500/42M 176449-02 module plays a crucial role in industrial automation systems due to its high performance, precision, and flexibility. It not only improves the efficiency of testing and measurement, but also ensures the accuracy and reliability of monitoring data, providing strong support for the operation and maintenance of equipment in enterprises.

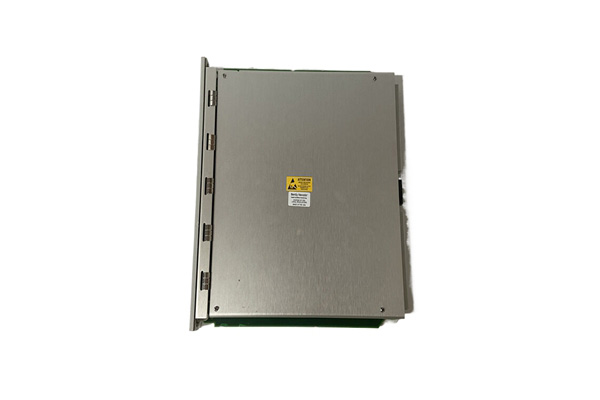

Bently Nevada 3500/42M 176449-02 high-precision Monitoring Module

Module Number:3500/42M 176449-02

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The BENTLY 3500/42M 176449-02 module is a high-performance and high-precision monitoring module widely used in industrial automation systems, especially in equipment operation and maintenance in industries such as energy, oil and natural gas, and chemical engineering. The following is a detailed introduction to this module.

Module Overview

The BENTLY 3500/42M 176449-02 module is designed specifically for monitoring the vibration and displacement of mechanical equipment. It can monitor the vibration level and displacement changes of rotating mechanical equipment in real time, help evaluate the operating status of the equipment, detect abnormal situations in a timely manner, and make adjustments to ensure the reliability and safety of the equipment.

Main features

High precision measurement:

This module provides up to 24 bit resolution and low noise levels, enabling accurate analog signal measurement.

Has excellent linearity and low drift performance, ensuring accurate measurement results over a wide dynamic range.

Multi channel monitoring:

As a configurable 4-channel monitoring module, it can simultaneously monitor multiple parameters such as radial vibration, axial displacement, eccentricity, REBAM, and differential expansion, improving the efficiency of testing and measurement.

Flexible input range:

Support multiple adjustable input ranges to adapt to the amplitude requirements of different signal sources, enhancing measurement flexibility and accuracy.

Built in calibration function:

Equipped with built-in automatic calibration function, it can calibrate each channel during the measurement process, improving measurement accuracy and reliability.

In addition, it also supports standard calibration procedures to further ensure the consistency and accuracy of measurement results.

High speed data transmission:

Adopting PXIE bus interface, it has high-speed data transmission capability and can quickly transmit collected data to the computer for processing and analysis.

Powerful software support:

Tightly integrated with NI’s LabVIEW and other software tools, it provides rich functionality and easy-to-use programming interfaces, making it convenient for users to perform data collection, real-time monitoring, automated testing, and remote control operations.

Application field

The BENTLY 3500/42M 176449-02 module plays an important role in multiple industrial fields, including but not limited to:

Energy industry: used in power plants, power plants, and other energy facilities to monitor the bearing status and vibration levels of rotating equipment such as generators, turbines, and wind turbines.

The oil and gas industry: used to monitor the vibration levels of rotating equipment such as pumps and compressors in oil drilling, refineries, and natural gas processing facilities.

Chemical industry: used to monitor the vibration and displacement of rotating equipment such as mixers, centrifuges, and pumps in the chemical production process.

Summary

The BENTLY 3500/42M 176449-02 module plays a crucial role in industrial automation systems due to its high performance, precision, and flexibility. It not only improves the efficiency of testing and measurement, but also ensures the accuracy and reliability of monitoring data, providing strong support for the operation and maintenance of equipment in enterprises.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...