Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

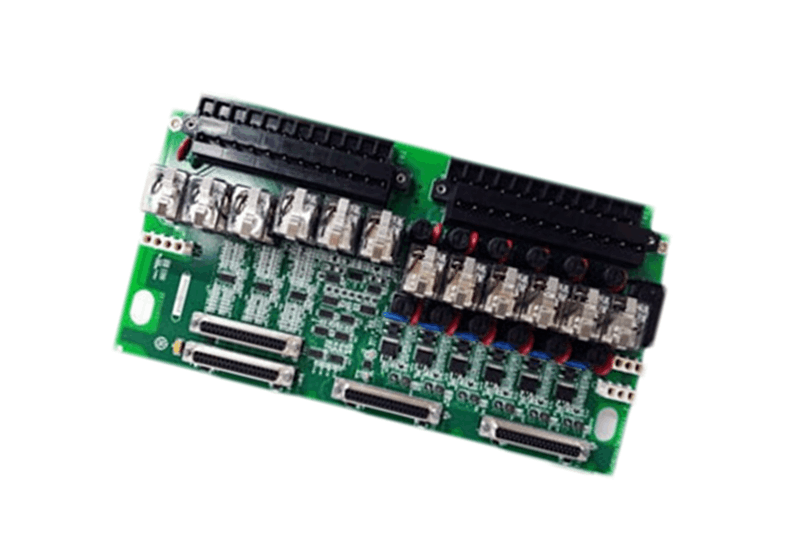

General Electric IS200VSPAH1A Monitoring Assembly Module

Manufacturer:GE

Product Number:IS200VSPAH1A

Product Type:Monitoring Assembly Module

Origin:USA

Dimensions:178 x 330.2 x 43 mm

Weight:0.25 kg

Views:15

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200VSPAH1A Monitoring Assembly Module is a critical component of the GE Mark VIe distributed control system, designed to provide high-performance monitoring and signal processing for complex industrial operations. This module is engineered to collect, filter, and condition a variety of analog and digital signals from field devices, delivering precise real-time data to the turbine control system. With a rugged PCB design and advanced diagnostic capability, the IS200VSPAH1A ensures dependable operation in demanding environments such as power generation plants, petrochemical facilities, and heavy industrial automation.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS200VSPAH1A |

| Series | GE Mark VIe Control System |

| Primary Function | High-speed monitoring and signal conditioning |

| Power Supply | 24 V DC nominal (operating range: 18–30 V DC) |

| Input Types | Analog voltage, analog current, and discrete digital signals |

| Output Interfaces | Ethernet, RS-485, Mark VIe proprietary backplane bus |

| Signal Conditioning | Integrated filtering and galvanic isolation |

| Operating Temperature | –40 °C to +70 °C |

| Humidity | 0–95 % non-condensing |

| Vibration Resistance | Up to 5 g, 10–2000 Hz |

| Shock Resistance | 30 g, 11 ms half-sine |

| Diagnostic Features | Built-in self-test, continuous health monitoring |

| Firmware Support | Mark VIe standard firmware with advanced diagnostics |

| Dimensions (W×H×D) | 178 x 330.2 x 43 mm |

| Weight | 0.25 kg |

| Mounting | Rack-mounted or panel-mounted |

| Board Material | FR4 PCB with conformal protective coating |

Applications

The IS200VSPAH1A module is versatile and suitable for a broad range of industrial applications, including:

Gas and Steam Turbines: Continuous monitoring of critical operating parameters to support stable turbine performance.

Power Generation Plants: Integration into distributed control systems for precise process control and protection.

Petrochemical Plants: Real-time acquisition and analysis of complex process signals for safety and efficiency.

Heavy Industrial Automation: High-speed feedback for process optimization and predictive maintenance.

Redundant System Architectures: Reliable data delivery in triple modular redundancy (TMR) environments.

Advantages

High-Resolution Monitoring: Accurate acquisition of analog and digital signals with minimal noise.

Advanced Isolation: Galvanic isolation safeguards sensitive control electronics from field-level disturbances.

Robust Communication: Supports Ethernet and RS-485, along with native Mark VIe backplane connectivity for seamless integration.

Industrial Durability: Built to endure extreme temperatures, vibration, and electrical interference.

Built-in Diagnostics: Continuous self-checking with automated fault detection reduces downtime.

Scalable Design: Compatible with expansion modules for additional I/O and custom configurations.

Frequently Asked Questions (FAQ)

What signal filtering techniques are implemented on the IS200VSPAH1A?

It employs multi-stage analog filtering combined with digital noise rejection to ensure clean signal acquisition.

How does the module manage galvanic isolation for multiple channels?

Each input and output channel is individually isolated to prevent ground loops and cross-channel interference.

Is real-time data buffering available in case of communication delays?

Yes, the board incorporates a high-speed buffer to temporarily store data during network interruptions.

How does the module synchronize data with the Mark VIe controller?

It uses a time-stamped protocol synchronized via the system’s master clock for deterministic operation.

Does the board support Modbus communication with third-party devices?

Yes, Modbus/TCP or RS-485 Modbus RTU can be configured through Mark VIe engineering tools.

What protection is provided against transient voltage spikes?

Surge suppressors and transient voltage suppressor (TVS) diodes are integrated on all external I/O.

How is firmware updated or patched in the field?

Firmware updates can be performed through the Mark VIe maintenance utility over the backplane or Ethernet.

Can the module participate in a triple modular redundancy setup?

Yes, it is fully compatible with TMR configurations for high availability.

How does the module indicate internal faults or diagnostics?

LED status indicators and system alarm messages are provided for rapid fault identification.

What is the typical scan rate achievable under full input load?

Less than 5 ms per cycle, ensuring real-time monitoring even with maximum I/O connections.

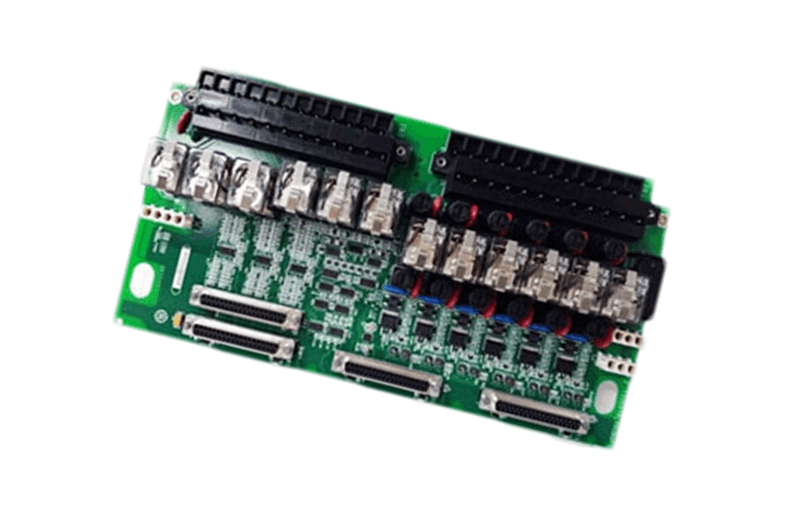

General Electric IS200VSPAH1A Monitoring Assembly Module

Manufacturer:GE

Product Number:IS200VSPAH1A

Product Type:Monitoring Assembly Module

Origin:USA

Dimensions:178 x 330.2 x 43 mm

Weight:0.25 kg

Views:15

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200VSPAH1A Monitoring Assembly Module is a critical component of the GE Mark VIe distributed control system, designed to provide high-performance monitoring and signal processing for complex industrial operations. This module is engineered to collect, filter, and condition a variety of analog and digital signals from field devices, delivering precise real-time data to the turbine control system. With a rugged PCB design and advanced diagnostic capability, the IS200VSPAH1A ensures dependable operation in demanding environments such as power generation plants, petrochemical facilities, and heavy industrial automation.

Product Specifications

| Parameter | Description |

|---|---|

| Model Number | IS200VSPAH1A |

| Series | GE Mark VIe Control System |

| Primary Function | High-speed monitoring and signal conditioning |

| Power Supply | 24 V DC nominal (operating range: 18–30 V DC) |

| Input Types | Analog voltage, analog current, and discrete digital signals |

| Output Interfaces | Ethernet, RS-485, Mark VIe proprietary backplane bus |

| Signal Conditioning | Integrated filtering and galvanic isolation |

| Operating Temperature | –40 °C to +70 °C |

| Humidity | 0–95 % non-condensing |

| Vibration Resistance | Up to 5 g, 10–2000 Hz |

| Shock Resistance | 30 g, 11 ms half-sine |

| Diagnostic Features | Built-in self-test, continuous health monitoring |

| Firmware Support | Mark VIe standard firmware with advanced diagnostics |

| Dimensions (W×H×D) | 178 x 330.2 x 43 mm |

| Weight | 0.25 kg |

| Mounting | Rack-mounted or panel-mounted |

| Board Material | FR4 PCB with conformal protective coating |

Applications

The IS200VSPAH1A module is versatile and suitable for a broad range of industrial applications, including:

Gas and Steam Turbines: Continuous monitoring of critical operating parameters to support stable turbine performance.

Power Generation Plants: Integration into distributed control systems for precise process control and protection.

Petrochemical Plants: Real-time acquisition and analysis of complex process signals for safety and efficiency.

Heavy Industrial Automation: High-speed feedback for process optimization and predictive maintenance.

Redundant System Architectures: Reliable data delivery in triple modular redundancy (TMR) environments.

Advantages

High-Resolution Monitoring: Accurate acquisition of analog and digital signals with minimal noise.

Advanced Isolation: Galvanic isolation safeguards sensitive control electronics from field-level disturbances.

Robust Communication: Supports Ethernet and RS-485, along with native Mark VIe backplane connectivity for seamless integration.

Industrial Durability: Built to endure extreme temperatures, vibration, and electrical interference.

Built-in Diagnostics: Continuous self-checking with automated fault detection reduces downtime.

Scalable Design: Compatible with expansion modules for additional I/O and custom configurations.

Frequently Asked Questions (FAQ)

What signal filtering techniques are implemented on the IS200VSPAH1A?

It employs multi-stage analog filtering combined with digital noise rejection to ensure clean signal acquisition.

How does the module manage galvanic isolation for multiple channels?

Each input and output channel is individually isolated to prevent ground loops and cross-channel interference.

Is real-time data buffering available in case of communication delays?

Yes, the board incorporates a high-speed buffer to temporarily store data during network interruptions.

How does the module synchronize data with the Mark VIe controller?

It uses a time-stamped protocol synchronized via the system’s master clock for deterministic operation.

Does the board support Modbus communication with third-party devices?

Yes, Modbus/TCP or RS-485 Modbus RTU can be configured through Mark VIe engineering tools.

What protection is provided against transient voltage spikes?

Surge suppressors and transient voltage suppressor (TVS) diodes are integrated on all external I/O.

How is firmware updated or patched in the field?

Firmware updates can be performed through the Mark VIe maintenance utility over the backplane or Ethernet.

Can the module participate in a triple modular redundancy setup?

Yes, it is fully compatible with TMR configurations for high availability.

How does the module indicate internal faults or diagnostics?

LED status indicators and system alarm messages are provided for rapid fault identification.

What is the typical scan rate achievable under full input load?

Less than 5 ms per cycle, ensuring real-time monitoring even with maximum I/O connections.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...