Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

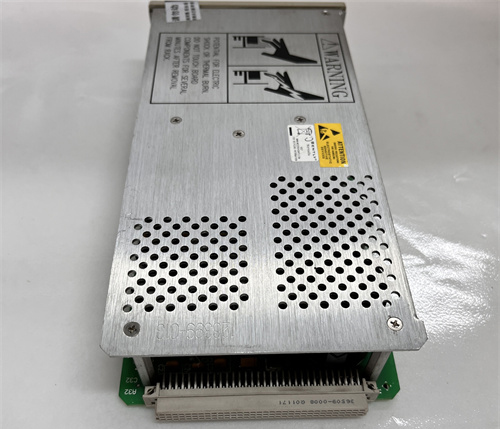

Bently Nevada 3500/42-09-00 140734-02+140471-01 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-09-00 140734-02+140471-01

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:44

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-09-00 Proximitor Seismic Monitor with associated part numbers 140734-02 and 140471-01 is a high-precision module used in the 3500 Series Machinery Protection System. Designed by Bently Nevada, a global leader in machinery condition monitoring, this seismic monitor module accurately detects and processes vibration and seismic signals from proximity transducers and seismic sensors.

This model is specifically engineered to provide continuous monitoring of rotating machinery and structural systems. It transforms raw sensor data into actionable output, enabling predictive maintenance, minimizing unexpected failures, and optimizing asset protection. It is often employed in high-stakes industrial environments such as power plants, oil and gas facilities, and chemical refineries where early detection of anomalies can prevent catastrophic equipment damage.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/42-09-00 |

| Part Numbers | 140734-02 + 140471-01 |

| Product Type | Proximitor Seismic Monitor Module |

| Manufacturer | Bently Nevada (GE Measurement & Control) |

| Monitoring Channels | Dual-channel (for vibration/seismic inputs) |

| Input Signal | Proximitor (proximity probe) or seismic sensor signals |

| Output Type | Buffered output, 4–20 mA current loop, relay (via 3500 Rack) |

| Display Type | None (signal output module-based) |

| Power Supply | Supplied via 3500 Rack – nominal 24 V DC |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 95% RH non-condensing |

| Dimensions (HxWxD) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Mounting | DIN-mounted within the 3500 Series Rack (19” rack system) |

| Compliance | CE, UL, CSA, RoHS |

Product Applications

The 3500/42-09-00 module plays a vital role in applications that require uninterrupted condition monitoring and protection of mechanical assets. Typical industries and applications include:

Power Generation: Monitoring vibration on turbines, generators, and critical auxiliaries.

Oil & Gas Refineries: Used for centrifugal compressors, gearboxes, and motor-driven pumps.

Petrochemical Plants: Providing real-time vibration and seismic feedback for rotating machinery.

Offshore Platforms: Monitoring structures and machinery exposed to harsh environmental conditions.

Steel and Mining Industry: Used in large-scale rotating equipment like crushers and mills.

Critical Infrastructure Monitoring: Structural monitoring in seismic-prone areas such as bridges or dams.

This module provides highly accurate feedback, which allows operators to take proactive maintenance steps, preventing failure and extending equipment life.

Product Advantages

High Sensitivity and Accuracy: Converts sensor data into precise digital output for fault detection and analysis.

Dual-Channel Capability: Simultaneous monitoring of two separate inputs increases flexibility and cost-efficiency.

Robust Industrial Design: Built to operate reliably under extreme industrial conditions and temperature fluctuations.

Continuous Online Monitoring: Ensures 24/7 data collection without downtime or manual intervention.

System Integration Ready: Seamlessly integrates with the Bently Nevada 3500 platform and plant-wide monitoring networks.

Reduced Downtime Risk: Enables early identification of mechanical issues, allowing timely corrective action.

Ease of Installation and Maintenance: Modular design supports plug-and-play installation within existing 3500 Racks.

Broad Sensor Compatibility: Works with proximity probes, velocity sensors, and seismic detectors.

Certified Compliance: Meets global standards for electrical safety and performance.

Frequently Asked Questions (FAQ)

What types of sensors can I use with the 3500/42-09-00 module?

This module supports Bently Nevada proximity probes and seismic sensors specifically designed for vibration and displacement monitoring.

Can it be installed as a standalone device?

No, it is designed to be used within a Bently Nevada 3500 rack system for full functionality.

How many channels does this module monitor?

It supports dual-channel monitoring, allowing two vibration/seismic inputs per module.

What type of output does it provide?

The module provides buffered output, 4–20 mA analog signals, and digital data for relays and alarms via the rack interface.

Is this model suitable for high-temperature environments?

It operates reliably in environments from -20°C to +70°C, suitable for most industrial installations.

Does it have any display or interface?

No local display is included; data visualization is handled via the 3500 rack system or connected monitoring software.

How is it powered?

It receives power from the 3500 Rack’s internal power supply (nominal 24V DC).

What certifications does it carry?

It complies with CE, UL, CSA, and RoHS standards, making it acceptable for global installations.

How often should this module be calibrated?

Calibration intervals vary by environment, but annual testing and calibration are generally recommended.

Can this module help with predictive maintenance?

Yes, it supports predictive maintenance strategies by delivering continuous, reliable monitoring data for analysis.

Bently Nevada 3500/42-09-00 140734-02+140471-01 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42-09-00 140734-02+140471-01

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:44

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42-09-00 Proximitor Seismic Monitor with associated part numbers 140734-02 and 140471-01 is a high-precision module used in the 3500 Series Machinery Protection System. Designed by Bently Nevada, a global leader in machinery condition monitoring, this seismic monitor module accurately detects and processes vibration and seismic signals from proximity transducers and seismic sensors.

This model is specifically engineered to provide continuous monitoring of rotating machinery and structural systems. It transforms raw sensor data into actionable output, enabling predictive maintenance, minimizing unexpected failures, and optimizing asset protection. It is often employed in high-stakes industrial environments such as power plants, oil and gas facilities, and chemical refineries where early detection of anomalies can prevent catastrophic equipment damage.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/42-09-00 |

| Part Numbers | 140734-02 + 140471-01 |

| Product Type | Proximitor Seismic Monitor Module |

| Manufacturer | Bently Nevada (GE Measurement & Control) |

| Monitoring Channels | Dual-channel (for vibration/seismic inputs) |

| Input Signal | Proximitor (proximity probe) or seismic sensor signals |

| Output Type | Buffered output, 4–20 mA current loop, relay (via 3500 Rack) |

| Display Type | None (signal output module-based) |

| Power Supply | Supplied via 3500 Rack – nominal 24 V DC |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 95% RH non-condensing |

| Dimensions (HxWxD) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Mounting | DIN-mounted within the 3500 Series Rack (19” rack system) |

| Compliance | CE, UL, CSA, RoHS |

Product Applications

The 3500/42-09-00 module plays a vital role in applications that require uninterrupted condition monitoring and protection of mechanical assets. Typical industries and applications include:

Power Generation: Monitoring vibration on turbines, generators, and critical auxiliaries.

Oil & Gas Refineries: Used for centrifugal compressors, gearboxes, and motor-driven pumps.

Petrochemical Plants: Providing real-time vibration and seismic feedback for rotating machinery.

Offshore Platforms: Monitoring structures and machinery exposed to harsh environmental conditions.

Steel and Mining Industry: Used in large-scale rotating equipment like crushers and mills.

Critical Infrastructure Monitoring: Structural monitoring in seismic-prone areas such as bridges or dams.

This module provides highly accurate feedback, which allows operators to take proactive maintenance steps, preventing failure and extending equipment life.

Product Advantages

High Sensitivity and Accuracy: Converts sensor data into precise digital output for fault detection and analysis.

Dual-Channel Capability: Simultaneous monitoring of two separate inputs increases flexibility and cost-efficiency.

Robust Industrial Design: Built to operate reliably under extreme industrial conditions and temperature fluctuations.

Continuous Online Monitoring: Ensures 24/7 data collection without downtime or manual intervention.

System Integration Ready: Seamlessly integrates with the Bently Nevada 3500 platform and plant-wide monitoring networks.

Reduced Downtime Risk: Enables early identification of mechanical issues, allowing timely corrective action.

Ease of Installation and Maintenance: Modular design supports plug-and-play installation within existing 3500 Racks.

Broad Sensor Compatibility: Works with proximity probes, velocity sensors, and seismic detectors.

Certified Compliance: Meets global standards for electrical safety and performance.

Frequently Asked Questions (FAQ)

What types of sensors can I use with the 3500/42-09-00 module?

This module supports Bently Nevada proximity probes and seismic sensors specifically designed for vibration and displacement monitoring.

Can it be installed as a standalone device?

No, it is designed to be used within a Bently Nevada 3500 rack system for full functionality.

How many channels does this module monitor?

It supports dual-channel monitoring, allowing two vibration/seismic inputs per module.

What type of output does it provide?

The module provides buffered output, 4–20 mA analog signals, and digital data for relays and alarms via the rack interface.

Is this model suitable for high-temperature environments?

It operates reliably in environments from -20°C to +70°C, suitable for most industrial installations.

Does it have any display or interface?

No local display is included; data visualization is handled via the 3500 rack system or connected monitoring software.

How is it powered?

It receives power from the 3500 Rack’s internal power supply (nominal 24V DC).

What certifications does it carry?

It complies with CE, UL, CSA, and RoHS standards, making it acceptable for global installations.

How often should this module be calibrated?

Calibration intervals vary by environment, but annual testing and calibration are generally recommended.

Can this module help with predictive maintenance?

Yes, it supports predictive maintenance strategies by delivering continuous, reliable monitoring data for analysis.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...