Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

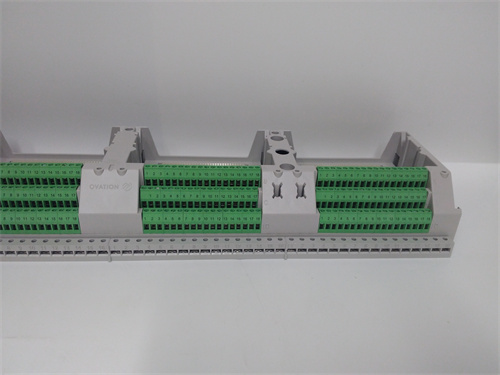

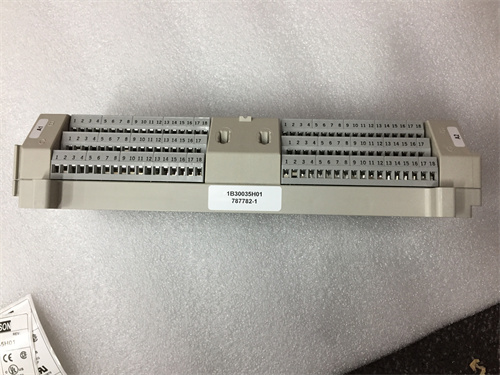

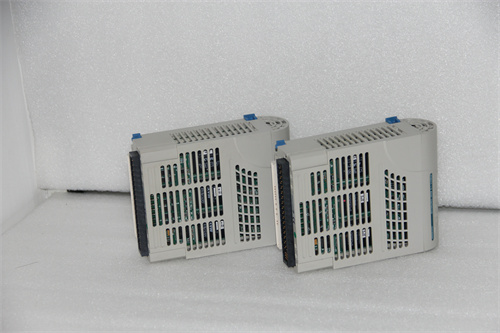

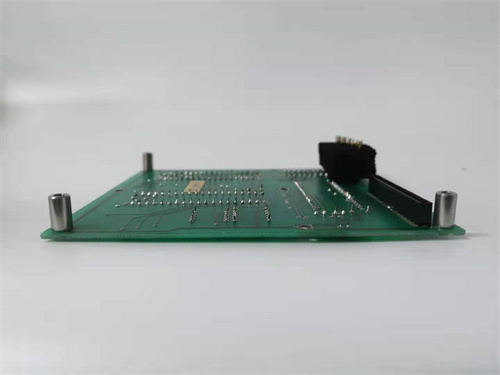

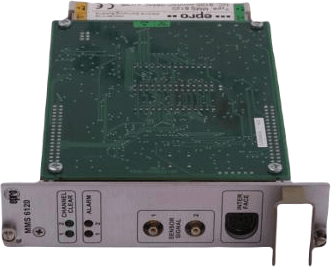

Emerson KJ2002X1-BA1 Controller Module

Manufacturer:Emerson

Product Number:KJ2002X1-BA1

Product Type:Controller Module

Origin:USA

Dimensions:250 x 200 x 100 mm

Weight:2.5 kg

Views:99

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Emerson KJ2002X1-BA1 is a high-performance controller module designed for the DeltaV™ Distributed Control System (DCS) platform. As the central processing unit of a DeltaV node, this controller orchestrates the communication between I/O modules, field devices, and the system network, enabling real-time control, diagnostics, and data acquisition for complex industrial automation processes.

Built for reliability, scalability, and system integration, the KJ2002X1-BA1 features redundant capability, secure communication protocols, and high-speed processing, allowing it to handle demanding control strategies. This controller is typically used in mission-critical process industries such as oil & gas, chemicals, pharmaceuticals, and power generation.

With native support for DeltaV’s plug-and-play architecture, the controller is easily configured through intuitive software tools, minimizing system complexity and commissioning time. Its rugged construction ensures long-term durability even in the harshest industrial environments.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Model | KJ2002X1-BA1 |

| Manufacturer | Emerson Process Management |

| Product Type | DeltaV Controller Module |

| System Compatibility | DeltaV DCS |

| Processor | 32-bit embedded processor |

| Memory | 64 MB SDRAM; 64 MB Flash |

| Scan Time | 100 ms typical (configurable) |

| Max Control Modules | Up to 250 |

| Max IO Channels Supported | 30,000+ with extended architecture |

| Communication Ports | 2 × Ethernet (10/100 Mbps), 1 × RS-232 |

| Supported Protocols | DeltaV, OPC, Modbus, HART pass-through |

| Redundancy Support | Yes – Controller and network redundancy supported |

| Real-Time Clock | Yes – Battery-backed RTC |

| Hot-Swappable | Yes |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95%, non-condensing |

| Certifications | CE, UL, CSA, FM, ATEX (Zone 2), RoHS |

| Shock & Vibration | IEC 60068-2-6 compliant |

| Mounting Type | Controller carrier or backplane mount |

| Dimensions (H × W × D) | 250 x 200 x 100 mm |

| Weight | 2.5 kg |

Product Applications

Process Control in Distributed Systems

Core component in DeltaV architectures, managing control logic and I/O processing.

Oil & Gas Facilities

Used to automate upstream and downstream operations with reliability and high throughput.

Power Generation

Provides central logic control and monitoring in both fossil and renewable energy plants.

Chemical and Petrochemical Plants

Executes advanced process control (APC) algorithms for safety and performance.

Pharmaceutical Manufacturing

Supports validated control strategies aligned with GMP requirements.

Water and Wastewater Treatment

Facilitates automated operations and remote monitoring for utility networks.

Product Advantages

DeltaV Native Integration

Seamlessly connects with DeltaV I/O, field devices, and engineering tools with minimal configuration.

High-Speed Processing

Handles complex logic and extensive I/O points with low-latency execution.

Redundancy Built-In

Supports controller and network redundancy to ensure operational continuity.

Plug-and-Play Deployment

Auto-recognition and configuration with DeltaV hardware and software tools reduce setup time.

Secure and Reliable Communication

Ethernet interfaces with integrated security and deterministic control performance.

Future-Proof Design

Scalable memory and I/O handling capability accommodate future expansions.

Long-Life Industrial Build

Designed to withstand industrial-grade temperature, vibration, and EMI environments.

Hot-Swappable Module

Enables field replacement without system shutdown, minimizing downtime.

Standards Compliance

Certified for use in hazardous locations and compliant with global industrial safety standards.

Low Maintenance

Passive cooling, robust enclosure, and long component life reduce upkeep costs.

Frequently Asked Questions (FAQ)

Q: What is the primary function of the KJ2002X1-BA1 controller?

A: It serves as the central processing unit for a DeltaV system, managing all control logic and communication.

Q: Can this controller be used in redundant configurations?

A: Yes, the KJ2002X1-BA1 fully supports controller and communication redundancy.

Q: How many I/O channels can this controller manage?

A: It can support over 30,000 I/O channels depending on system configuration and expansion.

Q: Is the controller hot-swappable?

A: Yes, it can be replaced without powering down the system when installed on compatible carriers.

Q: What communication interfaces are available?

A: Two Ethernet ports and one RS-232 port are provided for system and device communication.

Q: What are its certifications for hazardous areas?

A: It is ATEX Zone 2 certified and also holds CE, UL, CSA, and FM approvals.

Q: Does the controller have internal memory?

A: Yes, it comes with 64 MB of SDRAM and 64 MB of flash memory.

Q: What protocols does it support?

A: It supports DeltaV native protocols, OPC, Modbus, and HART pass-through.

Q: What operating temperature range can it tolerate?

A: The controller is rated for -40°C to +70°C operation.

Q: How is it configured and maintained?

A: Configuration is done via the DeltaV Explorer and Control Studio tools, with status LEDs for diagnostics.

Emerson KJ2002X1-BA1 Controller Module

Manufacturer:Emerson

Product Number:KJ2002X1-BA1

Product Type:Controller Module

Origin:USA

Dimensions:250 x 200 x 100 mm

Weight:2.5 kg

Views:99

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Emerson KJ2002X1-BA1 is a high-performance controller module designed for the DeltaV™ Distributed Control System (DCS) platform. As the central processing unit of a DeltaV node, this controller orchestrates the communication between I/O modules, field devices, and the system network, enabling real-time control, diagnostics, and data acquisition for complex industrial automation processes.

Built for reliability, scalability, and system integration, the KJ2002X1-BA1 features redundant capability, secure communication protocols, and high-speed processing, allowing it to handle demanding control strategies. This controller is typically used in mission-critical process industries such as oil & gas, chemicals, pharmaceuticals, and power generation.

With native support for DeltaV’s plug-and-play architecture, the controller is easily configured through intuitive software tools, minimizing system complexity and commissioning time. Its rugged construction ensures long-term durability even in the harshest industrial environments.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Model | KJ2002X1-BA1 |

| Manufacturer | Emerson Process Management |

| Product Type | DeltaV Controller Module |

| System Compatibility | DeltaV DCS |

| Processor | 32-bit embedded processor |

| Memory | 64 MB SDRAM; 64 MB Flash |

| Scan Time | 100 ms typical (configurable) |

| Max Control Modules | Up to 250 |

| Max IO Channels Supported | 30,000+ with extended architecture |

| Communication Ports | 2 × Ethernet (10/100 Mbps), 1 × RS-232 |

| Supported Protocols | DeltaV, OPC, Modbus, HART pass-through |

| Redundancy Support | Yes – Controller and network redundancy supported |

| Real-Time Clock | Yes – Battery-backed RTC |

| Hot-Swappable | Yes |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95%, non-condensing |

| Certifications | CE, UL, CSA, FM, ATEX (Zone 2), RoHS |

| Shock & Vibration | IEC 60068-2-6 compliant |

| Mounting Type | Controller carrier or backplane mount |

| Dimensions (H × W × D) | 250 x 200 x 100 mm |

| Weight | 2.5 kg |

Product Applications

Process Control in Distributed Systems

Core component in DeltaV architectures, managing control logic and I/O processing.

Oil & Gas Facilities

Used to automate upstream and downstream operations with reliability and high throughput.

Power Generation

Provides central logic control and monitoring in both fossil and renewable energy plants.

Chemical and Petrochemical Plants

Executes advanced process control (APC) algorithms for safety and performance.

Pharmaceutical Manufacturing

Supports validated control strategies aligned with GMP requirements.

Water and Wastewater Treatment

Facilitates automated operations and remote monitoring for utility networks.

Product Advantages

DeltaV Native Integration

Seamlessly connects with DeltaV I/O, field devices, and engineering tools with minimal configuration.

High-Speed Processing

Handles complex logic and extensive I/O points with low-latency execution.

Redundancy Built-In

Supports controller and network redundancy to ensure operational continuity.

Plug-and-Play Deployment

Auto-recognition and configuration with DeltaV hardware and software tools reduce setup time.

Secure and Reliable Communication

Ethernet interfaces with integrated security and deterministic control performance.

Future-Proof Design

Scalable memory and I/O handling capability accommodate future expansions.

Long-Life Industrial Build

Designed to withstand industrial-grade temperature, vibration, and EMI environments.

Hot-Swappable Module

Enables field replacement without system shutdown, minimizing downtime.

Standards Compliance

Certified for use in hazardous locations and compliant with global industrial safety standards.

Low Maintenance

Passive cooling, robust enclosure, and long component life reduce upkeep costs.

Frequently Asked Questions (FAQ)

Q: What is the primary function of the KJ2002X1-BA1 controller?

A: It serves as the central processing unit for a DeltaV system, managing all control logic and communication.

Q: Can this controller be used in redundant configurations?

A: Yes, the KJ2002X1-BA1 fully supports controller and communication redundancy.

Q: How many I/O channels can this controller manage?

A: It can support over 30,000 I/O channels depending on system configuration and expansion.

Q: Is the controller hot-swappable?

A: Yes, it can be replaced without powering down the system when installed on compatible carriers.

Q: What communication interfaces are available?

A: Two Ethernet ports and one RS-232 port are provided for system and device communication.

Q: What are its certifications for hazardous areas?

A: It is ATEX Zone 2 certified and also holds CE, UL, CSA, and FM approvals.

Q: Does the controller have internal memory?

A: Yes, it comes with 64 MB of SDRAM and 64 MB of flash memory.

Q: What protocols does it support?

A: It supports DeltaV native protocols, OPC, Modbus, and HART pass-through.

Q: What operating temperature range can it tolerate?

A: The controller is rated for -40°C to +70°C operation.

Q: How is it configured and maintained?

A: Configuration is done via the DeltaV Explorer and Control Studio tools, with status LEDs for diagnostics.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...