Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

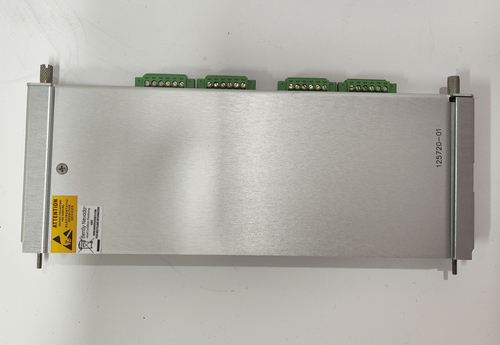

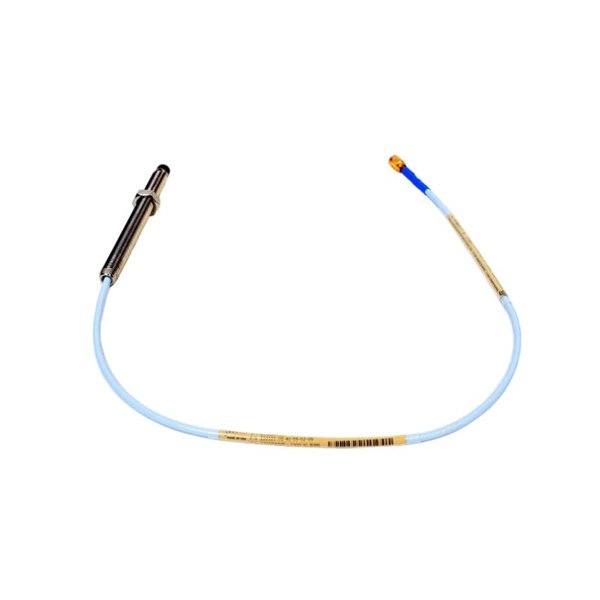

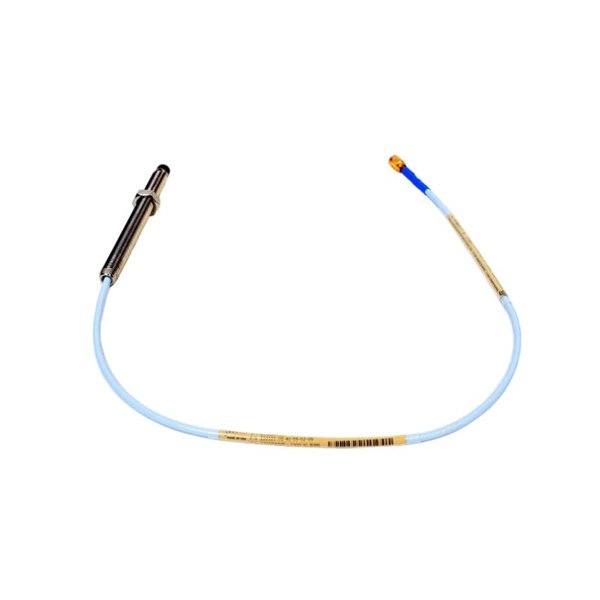

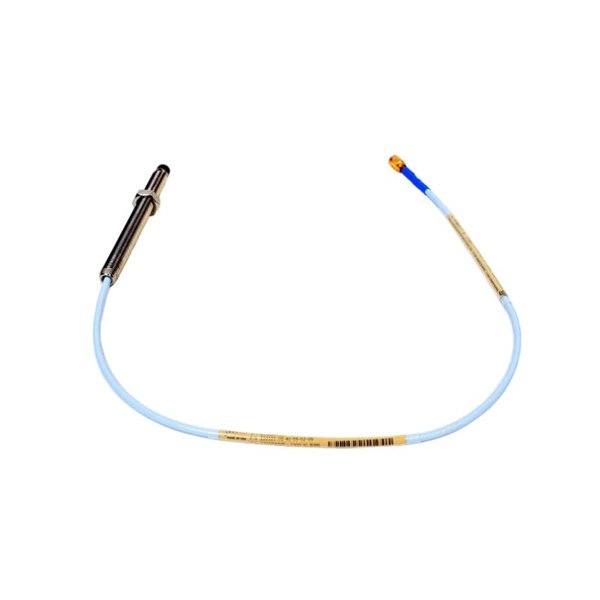

Bently Nevada 330103-00-03-10-02-R0 3300 XL 8 mm proximity probe

Manufacturer:Bently Nevada

Product Number:330103-00-03-10-02-R0

Product Type:3300 XL 8 mm proximity probe

Origin:USA

Total Length:1.0 meter

Weight:0.323kg

Views:20

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-03-10-02-R0 is an advanced 8 mm proximity probe from the 3300 XL series, designed for high-precision vibration and position monitoring in rotating machinery. It offers exceptional accuracy, durability, and ease of integration, making it ideal for critical applications in industries such as power generation, oil & gas, and manufacturing.

Product Specifications

| Parameter | Description |

|---|---|

| Model | 330103-00-03-10-02-R0 |

| Thread Type | M10 x 1 |

| Measurement Range | 8 mm |

| Overall Case Length | 30 mm |

| Total Length | 1.0 meter (3.3 feet) |

| Connector Type | Miniature coaxial ClickLoc connector |

| Cable Type | Standard cable |

| Sensitivity | 0.5 V/mm |

| Frequency Response | 0–10 kHz |

| Probe Case Material | AISI 303 or 304 stainless steel |

| Weight | 0.323 kg |

Applications

Vibration Monitoring: Detects radial and axial vibrations in rotating machinery to prevent failures.

Shaft Position Measurement: Measures the position of shafts to ensure proper alignment and operation.

Keyphasor® and Speed Measurement: Provides accurate timing signals for synchronization and control systems.

API 670 Compliance: Meets the standards set by the American Petroleum Institute for machinery protection systems.

Product Advantages

High Accuracy: Provides precise measurements for critical machinery monitoring.

Interchangeability: Components are interchangeable without the need for individual calibration.

API 670 Compliance: Fully compliant with industry standards for machinery protection.

Robust Design: Built to withstand harsh industrial environments.

Easy Integration: Compatible with existing Bently Nevada systems and accessories.

FAQ

Q1: How do I properly install the 330103-00-03-10-02-R0 probe to ensure accurate measurements?

A1: Ensure the probe is securely mounted perpendicular to the shaft, maintaining the recommended gap. Avoid placing the probe near sources of electromagnetic interference.

Q2: Can this probe be used with other 3300 XL series monitoring systems?

A2: Yes, it is fully compatible with all standard 3300 XL series modules and monitoring systems.

Q3: What are the best practices for cable routing to minimize signal noise?

A3: Keep probe cables away from high-voltage lines and rotating machinery. Use shielded cable and maintain tight connectors.

Q4: How can I verify the probe is functioning correctly after installation?

A4: Use the system’s built-in self-test and check for proper Keyphasor® pulse output and vibration signal readings.

Q5: Is this probe suitable for high-speed rotating machinery?

A5: Yes, it is designed for high-speed applications up to the rated shaft RPM specified by the 3300 XL series.

Q6: How do I handle alignment issues between probe and shaft?

A6: Adjust the probe to ensure the sensing tip is centered and parallel to the shaft. Use the recommended feeler gauges for initial setup.

Q7: Can the probe operate in environments with moderate dust or moisture?

A7: Yes, the probe has a robust industrial design but avoid submerging it or exposing it to corrosive chemicals.

Q8: How do I detect a failing probe before it impacts machinery monitoring?

A8: Monitor signal consistency and Keyphasor® pulses. Anomalies like signal dropouts or excessive noise indicate potential probe issues.

Q9: Can this probe be replaced without recalibrating the monitoring system?

A9: Yes, as part of the 3300 XL series, it is interchangeable without individual recalibration.

Q10: What troubleshooting steps are recommended if vibration readings seem inaccurate?

A10: Check the gap between probe and shaft, ensure cables are correctly connected, verify system settings, and rule out electrical interference.

Bently Nevada 330103-00-03-10-02-R0 3300 XL 8 mm proximity probe

Manufacturer:Bently Nevada

Product Number:330103-00-03-10-02-R0

Product Type:3300 XL 8 mm proximity probe

Origin:USA

Total Length:1.0 meter

Weight:0.323kg

Views:20

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-03-10-02-R0 is an advanced 8 mm proximity probe from the 3300 XL series, designed for high-precision vibration and position monitoring in rotating machinery. It offers exceptional accuracy, durability, and ease of integration, making it ideal for critical applications in industries such as power generation, oil & gas, and manufacturing.

Product Specifications

| Parameter | Description |

|---|---|

| Model | 330103-00-03-10-02-R0 |

| Thread Type | M10 x 1 |

| Measurement Range | 8 mm |

| Overall Case Length | 30 mm |

| Total Length | 1.0 meter (3.3 feet) |

| Connector Type | Miniature coaxial ClickLoc connector |

| Cable Type | Standard cable |

| Sensitivity | 0.5 V/mm |

| Frequency Response | 0–10 kHz |

| Probe Case Material | AISI 303 or 304 stainless steel |

| Weight | 0.323 kg |

Applications

Vibration Monitoring: Detects radial and axial vibrations in rotating machinery to prevent failures.

Shaft Position Measurement: Measures the position of shafts to ensure proper alignment and operation.

Keyphasor® and Speed Measurement: Provides accurate timing signals for synchronization and control systems.

API 670 Compliance: Meets the standards set by the American Petroleum Institute for machinery protection systems.

Product Advantages

High Accuracy: Provides precise measurements for critical machinery monitoring.

Interchangeability: Components are interchangeable without the need for individual calibration.

API 670 Compliance: Fully compliant with industry standards for machinery protection.

Robust Design: Built to withstand harsh industrial environments.

Easy Integration: Compatible with existing Bently Nevada systems and accessories.

FAQ

Q1: How do I properly install the 330103-00-03-10-02-R0 probe to ensure accurate measurements?

A1: Ensure the probe is securely mounted perpendicular to the shaft, maintaining the recommended gap. Avoid placing the probe near sources of electromagnetic interference.

Q2: Can this probe be used with other 3300 XL series monitoring systems?

A2: Yes, it is fully compatible with all standard 3300 XL series modules and monitoring systems.

Q3: What are the best practices for cable routing to minimize signal noise?

A3: Keep probe cables away from high-voltage lines and rotating machinery. Use shielded cable and maintain tight connectors.

Q4: How can I verify the probe is functioning correctly after installation?

A4: Use the system’s built-in self-test and check for proper Keyphasor® pulse output and vibration signal readings.

Q5: Is this probe suitable for high-speed rotating machinery?

A5: Yes, it is designed for high-speed applications up to the rated shaft RPM specified by the 3300 XL series.

Q6: How do I handle alignment issues between probe and shaft?

A6: Adjust the probe to ensure the sensing tip is centered and parallel to the shaft. Use the recommended feeler gauges for initial setup.

Q7: Can the probe operate in environments with moderate dust or moisture?

A7: Yes, the probe has a robust industrial design but avoid submerging it or exposing it to corrosive chemicals.

Q8: How do I detect a failing probe before it impacts machinery monitoring?

A8: Monitor signal consistency and Keyphasor® pulses. Anomalies like signal dropouts or excessive noise indicate potential probe issues.

Q9: Can this probe be replaced without recalibrating the monitoring system?

A9: Yes, as part of the 3300 XL series, it is interchangeable without individual recalibration.

Q10: What troubleshooting steps are recommended if vibration readings seem inaccurate?

A10: Check the gap between probe and shaft, ensure cables are correctly connected, verify system settings, and rule out electrical interference.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...