Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

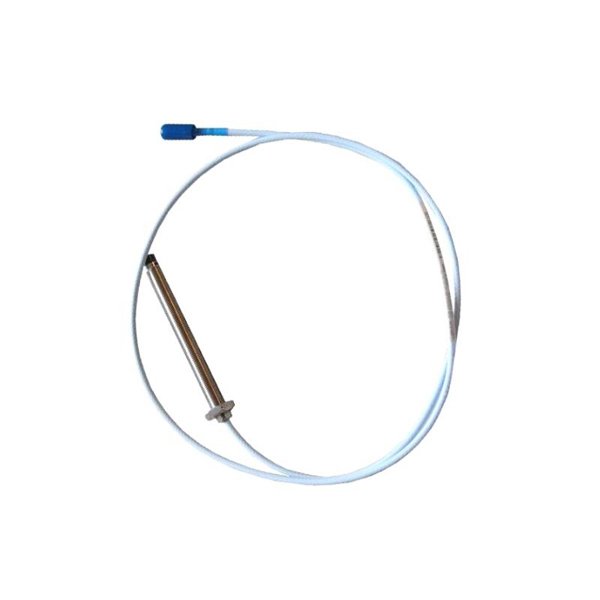

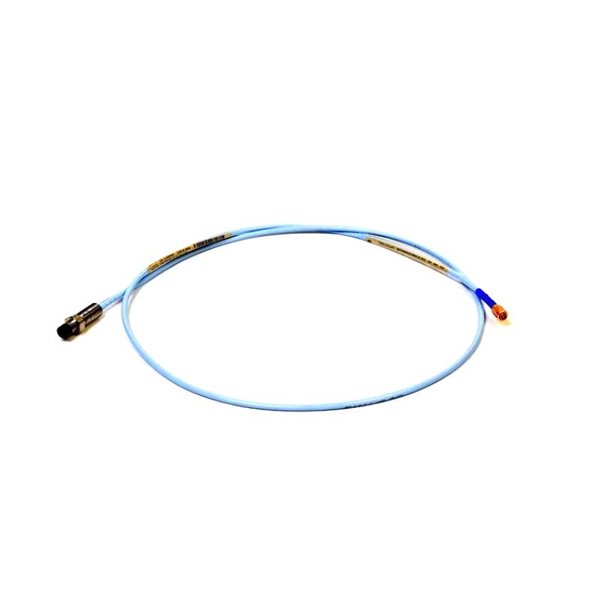

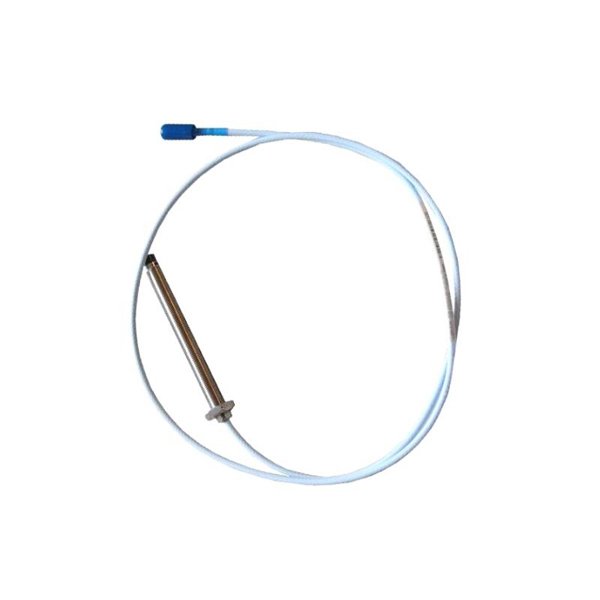

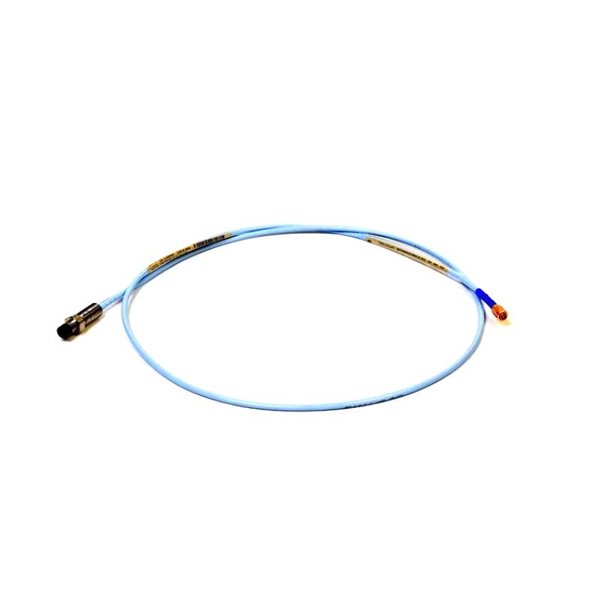

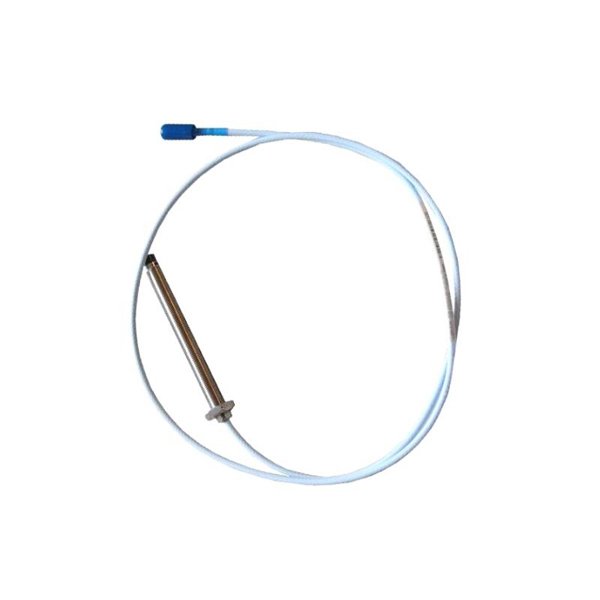

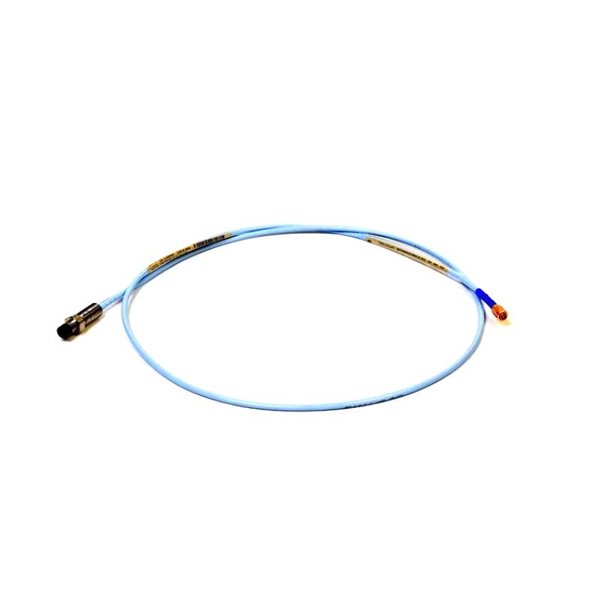

Bently Nevada 330104-00-08-10-01-00 3300 XL 8 mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330104-00-08-10-01-00

Product Type:3300 XL 8 mm Proximity Probes

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300 XL 8 mm Proximity Probe, part number 330104-00-08-10-01-00, is a high-precision sensor designed for non-contact measurement of shaft position and vibration in industrial machinery. It is an integral component of the 3300 XL Proximity Transducer System, renowned for its reliability and accuracy in monitoring rotating equipment. This probe is engineered to withstand harsh industrial environments, providing consistent performance in critical applications.

Key Features

Non-Contact Measurement: Enables accurate monitoring of shaft position and vibration without physical contact, reducing wear and maintenance.

High Precision: Delivers precise measurements essential for assessing machinery health and performance.

Robust Construction: Built to endure extreme temperatures and environmental conditions, ensuring long-term reliability.

Interchangeability: Fully interchangeable with other 3300 series components, facilitating easy system upgrades and replacements.

Compliance with Standards: Meets API 670 standards for mechanical configuration, linear range, accuracy, and temperature stability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Part Number | 330104-00-08-10-01-00 |

| Probe Tip Diameter | 8 mm |

| Measurement Range | 0 to 2 mm |

| Linear Range | 0.25 to 2.25 mm |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Frequency Response | 0 to 10 kHz |

| Operating Temperature Range | -51°C to +177°C (-60°F to +350°F) |

| Probe Pressure Rating | Up to 500 psi |

| Probe Case Material | AISI 303 Stainless Steel |

| Probe Tip Material | Polyphenylene Sulfide (PPS) |

| Total Length | 1 meters |

| Dimensions | Probe Length: 50 mm; Cable Diameter: 5 mm |

| Weight | 0.323 kg |

Applications

The 3300 XL 8 mm Proximity Probe is widely used in various industries for monitoring and protecting critical machinery, including:

Power Generation: Monitoring turbines, generators, and other rotating equipment to ensure operational efficiency and prevent failures.

Oil and Gas: Assessing the condition of compressors, pumps, and drilling equipment to maintain safety and performance.

Manufacturing: Overseeing the health of motors, conveyors, and production machinery to minimize downtime and maintenance costs.

Chemical Processing: Ensuring the reliability of mixers, centrifuges, and other process equipment critical to production quality.

Advantages

Enhanced Machinery Protection: Provides early detection of potential issues, allowing for proactive maintenance and reducing the risk of unexpected failures.

Durable Design: Capable of withstanding harsh environmental conditions, including high temperatures and pressures, ensuring consistent performance.

Ease of Integration: Designed for compatibility with existing Bently Nevada monitoring systems, simplifying installation and system expansion.

Cost-Effective Maintenance: Non-contact measurement reduces mechanical wear, extending the lifespan of both the probe and the monitored equipment.

Frequently Asked Questions (FAQs)

What is the primary function of the 3300 XL 8 mm Proximity Probe?

-

It measures the position and vibration of rotating machinery shafts without physical contact, aiding in condition monitoring and diagnostics.

-

Is the probe compatible with other Bently Nevada systems?

-

Yes, it is fully compatible and interchangeable with other 3300 series components, facilitating seamless integration.

-

What environmental conditions can the probe withstand?

-

It operates effectively in temperatures ranging from -51°C to +177°C and can endure pressures up to 500 psi.

-

How does the probe contribute to machinery protection?

-

By providing accurate measurements of shaft position and vibration, it enables early detection of potential issues, allowing for timely maintenance and preventing unexpected failures.

-

What materials are used in the construction of the probe?

-

The probe case is made of AISI 303 Stainless Steel, and the probe tip is constructed from Polyphenylene Sulfide (PPS), ensuring durability and resistance to harsh conditions.

-

Can the probe be used in high-pressure environments?

-

Yes, it is rated to withstand pressures up to 500 psi, making it suitable for various industrial applications.

-

What is the measurement range of the probe?

-

It has a measurement range of 0 to 2 mm, with a linear range from 0.25 to 2.25 mm.

-

Does the probe require physical contact with the machinery?

-

No, it utilizes non-contact measurement techniques, reducing wear and maintenance requirements.

-

Is the probe compliant with industry standards?

-

Yes, it meets API 670 standards for mechanical configuration, linear range, accuracy, and temperature stability.

-

What is the sensitivity of the probe?

-

The probe has a sensitivity of 7.87 mV/μm (200 mV/mil), providing precise measurement capabilities.

-

Bently Nevada 330104-00-08-10-01-00 3300 XL 8 mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330104-00-08-10-01-00

Product Type:3300 XL 8 mm Proximity Probes

Origin:USA

Total Length:1 m

Weight:0.323 kg

Views:47

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300 XL 8 mm Proximity Probe, part number 330104-00-08-10-01-00, is a high-precision sensor designed for non-contact measurement of shaft position and vibration in industrial machinery. It is an integral component of the 3300 XL Proximity Transducer System, renowned for its reliability and accuracy in monitoring rotating equipment. This probe is engineered to withstand harsh industrial environments, providing consistent performance in critical applications.

Key Features

Non-Contact Measurement: Enables accurate monitoring of shaft position and vibration without physical contact, reducing wear and maintenance.

High Precision: Delivers precise measurements essential for assessing machinery health and performance.

Robust Construction: Built to endure extreme temperatures and environmental conditions, ensuring long-term reliability.

Interchangeability: Fully interchangeable with other 3300 series components, facilitating easy system upgrades and replacements.

Compliance with Standards: Meets API 670 standards for mechanical configuration, linear range, accuracy, and temperature stability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Part Number | 330104-00-08-10-01-00 |

| Probe Tip Diameter | 8 mm |

| Measurement Range | 0 to 2 mm |

| Linear Range | 0.25 to 2.25 mm |

| Sensitivity | 7.87 mV/μm (200 mV/mil) |

| Frequency Response | 0 to 10 kHz |

| Operating Temperature Range | -51°C to +177°C (-60°F to +350°F) |

| Probe Pressure Rating | Up to 500 psi |

| Probe Case Material | AISI 303 Stainless Steel |

| Probe Tip Material | Polyphenylene Sulfide (PPS) |

| Total Length | 1 meters |

| Dimensions | Probe Length: 50 mm; Cable Diameter: 5 mm |

| Weight | 0.323 kg |

Applications

The 3300 XL 8 mm Proximity Probe is widely used in various industries for monitoring and protecting critical machinery, including:

Power Generation: Monitoring turbines, generators, and other rotating equipment to ensure operational efficiency and prevent failures.

Oil and Gas: Assessing the condition of compressors, pumps, and drilling equipment to maintain safety and performance.

Manufacturing: Overseeing the health of motors, conveyors, and production machinery to minimize downtime and maintenance costs.

Chemical Processing: Ensuring the reliability of mixers, centrifuges, and other process equipment critical to production quality.

Advantages

Enhanced Machinery Protection: Provides early detection of potential issues, allowing for proactive maintenance and reducing the risk of unexpected failures.

Durable Design: Capable of withstanding harsh environmental conditions, including high temperatures and pressures, ensuring consistent performance.

Ease of Integration: Designed for compatibility with existing Bently Nevada monitoring systems, simplifying installation and system expansion.

Cost-Effective Maintenance: Non-contact measurement reduces mechanical wear, extending the lifespan of both the probe and the monitored equipment.

Frequently Asked Questions (FAQs)

What is the primary function of the 3300 XL 8 mm Proximity Probe?

-

It measures the position and vibration of rotating machinery shafts without physical contact, aiding in condition monitoring and diagnostics.

-

Is the probe compatible with other Bently Nevada systems?

-

Yes, it is fully compatible and interchangeable with other 3300 series components, facilitating seamless integration.

-

What environmental conditions can the probe withstand?

-

It operates effectively in temperatures ranging from -51°C to +177°C and can endure pressures up to 500 psi.

-

How does the probe contribute to machinery protection?

-

By providing accurate measurements of shaft position and vibration, it enables early detection of potential issues, allowing for timely maintenance and preventing unexpected failures.

-

What materials are used in the construction of the probe?

-

The probe case is made of AISI 303 Stainless Steel, and the probe tip is constructed from Polyphenylene Sulfide (PPS), ensuring durability and resistance to harsh conditions.

-

Can the probe be used in high-pressure environments?

-

Yes, it is rated to withstand pressures up to 500 psi, making it suitable for various industrial applications.

-

What is the measurement range of the probe?

-

It has a measurement range of 0 to 2 mm, with a linear range from 0.25 to 2.25 mm.

-

Does the probe require physical contact with the machinery?

-

No, it utilizes non-contact measurement techniques, reducing wear and maintenance requirements.

-

Is the probe compliant with industry standards?

-

Yes, it meets API 670 standards for mechanical configuration, linear range, accuracy, and temperature stability.

-

What is the sensitivity of the probe?

-

The probe has a sensitivity of 7.87 mV/μm (200 mV/mil), providing precise measurement capabilities.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...