Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

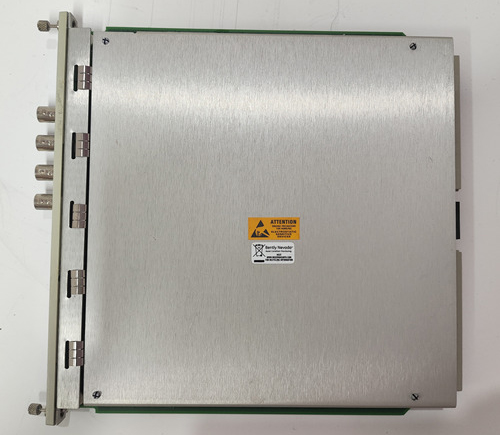

Bently Nevada 1900/27-02-00 Vibration Monitor

Manufacturer:Bently Nevada

Product Number:1900/27-02-00

Product Type:Vibration Monitor

Origin:USA

Dimensions:132 x 132 x 71.1 mm

Weight:0.4 kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 1900/27-02-00 Vibration Monitor is an industrial-grade instrument designed for continuous monitoring of machinery vibration to protect rotating equipment and optimize maintenance strategies. This model is part of Bently Nevada’s 1900 series, known for high reliability and accurate vibration measurement.

The 1900/27-02-00 provides precise real-time monitoring for turbines, compressors, pumps, and other critical rotating machinery. It can detect early-stage mechanical problems such as imbalance, misalignment, bearing wear, and looseness, preventing unplanned downtime and costly equipment failures. The monitor supports integration with various sensors, including proximity probes and accelerometers, and features configurable alarm outputs and signal processing capabilities.

Engineered for harsh industrial environments, this vibration monitor is robust against shock, vibration, oil, and moisture exposure. Its analog outputs and relay interfaces enable seamless integration with control systems and machinery protection programs, making it a reliable choice for predictive maintenance and machine condition monitoring.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 1900/27-02-00 Vibration Monitor |

| Monitor Type | Machinery vibration monitoring |

| Sensor Input | Proximity probes, accelerometers |

| Measurement Range | 0–50 mm/s velocity or 0–100 mil displacement (model dependent) |

| Frequency Response | 5 Hz – 15 kHz |

| Power Supply | 115/230 V AC, 50/60 Hz |

| Power Consumption | 12 W maximum |

| Operating Temperature Range | 0°C to 55°C |

| Storage Temperature Range | -20°C to 70°C |

| Humidity Tolerance | 5% to 95% RH, non-condensing |

| Alarm Outputs | SPDT relay outputs for high vibration, alert, and trip signals |

| Display | Analog meter with LED indicators |

| Dimensions (H × W × D) | 132 x 132 x 71.1 mm |

| Weight | 0.4 kg |

| Certifications | CE, UL, IEC standards |

| Environmental Resistance | Shock, vibration, oil, and moisture resistant |

| Connectivity | Relay outputs and analog output for DCS or PLC integration |

| Configuration | Adjustable alarm thresholds and frequency filters |

Product Applications

The 1900/27-02-00 Vibration Monitor is suitable for a wide range of industrial and critical applications:

-

Continuous vibration monitoring of turbines, compressors, generators, and pumps

-

Detection of imbalance, misalignment, bearing wear, and looseness in rotating machinery

-

Integration with DCS or PLC systems for machinery protection

-

Early warning and trip signaling to prevent catastrophic machinery failures

-

Condition monitoring during commissioning, routine inspections, and predictive maintenance

-

Retrofitting legacy machines for advanced vibration monitoring

-

Real-time monitoring in power plants, petrochemical, oil & gas, and manufacturing facilities

Product Advantages

High Accuracy: Provides precise measurement of vibration amplitude, velocity, and frequency.

Robust Construction: Resistant to shock, vibration, oil, and moisture for industrial reliability.

Sensor Flexibility: Compatible with proximity probes and accelerometers for versatile monitoring.

Configurable Alarms: Adjustable thresholds for alert, high vibration, and trip outputs.

Predictive Maintenance: Supports early detection of machinery faults to reduce downtime.

Easy Integration: Analog and relay outputs allow connection to DCS or PLC systems.

User-Friendly Interface: Analog meter and LED indicators provide clear visual feedback.

Extended Frequency Response: Supports detection of high-frequency vibrations for accurate diagnostics.

Frequently Asked Questions (FAQ)

What sensors are compatible with the 1900/27-02-00 monitor?

It supports proximity probes and accelerometers.

What is the measurement range of this monitor?

0–50 mm/s velocity or 0–100 mil displacement depending on configuration.

Can the alarm outputs be configured for multiple thresholds?

Yes, it supports adjustable thresholds for alert, high vibration, and trip signals.

What is the frequency response of this monitor?

5 Hz – 15 kHz.

Is the monitor suitable for high-humidity environments?

Yes, it operates reliably in 5% to 95% RH non-condensing conditions.

How does it communicate with DCS systems?

Through relay outputs and analog outputs compatible with standard DCS or PLC input modules.

Can it be used for both rotating and reciprocating machinery?

Yes, it is capable of monitoring vibration across various types of rotating equipment.

What temperature ranges are supported for operation?

0°C to 55°C operational, -20°C to 70°C storage.

Does the monitor provide visual indication of vibration status?

Yes, via analog meter and LED indicators.

Can this monitor be used for retrofitting existing machines?

Yes, it is ideal for retrofitting legacy machinery with advanced vibration monitoring capabilities.

Bently Nevada 1900/27-02-00 Vibration Monitor

Manufacturer:Bently Nevada

Product Number:1900/27-02-00

Product Type:Vibration Monitor

Origin:USA

Dimensions:132 x 132 x 71.1 mm

Weight:0.4 kg

Views:35

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 1900/27-02-00 Vibration Monitor is an industrial-grade instrument designed for continuous monitoring of machinery vibration to protect rotating equipment and optimize maintenance strategies. This model is part of Bently Nevada’s 1900 series, known for high reliability and accurate vibration measurement.

The 1900/27-02-00 provides precise real-time monitoring for turbines, compressors, pumps, and other critical rotating machinery. It can detect early-stage mechanical problems such as imbalance, misalignment, bearing wear, and looseness, preventing unplanned downtime and costly equipment failures. The monitor supports integration with various sensors, including proximity probes and accelerometers, and features configurable alarm outputs and signal processing capabilities.

Engineered for harsh industrial environments, this vibration monitor is robust against shock, vibration, oil, and moisture exposure. Its analog outputs and relay interfaces enable seamless integration with control systems and machinery protection programs, making it a reliable choice for predictive maintenance and machine condition monitoring.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 1900/27-02-00 Vibration Monitor |

| Monitor Type | Machinery vibration monitoring |

| Sensor Input | Proximity probes, accelerometers |

| Measurement Range | 0–50 mm/s velocity or 0–100 mil displacement (model dependent) |

| Frequency Response | 5 Hz – 15 kHz |

| Power Supply | 115/230 V AC, 50/60 Hz |

| Power Consumption | 12 W maximum |

| Operating Temperature Range | 0°C to 55°C |

| Storage Temperature Range | -20°C to 70°C |

| Humidity Tolerance | 5% to 95% RH, non-condensing |

| Alarm Outputs | SPDT relay outputs for high vibration, alert, and trip signals |

| Display | Analog meter with LED indicators |

| Dimensions (H × W × D) | 132 x 132 x 71.1 mm |

| Weight | 0.4 kg |

| Certifications | CE, UL, IEC standards |

| Environmental Resistance | Shock, vibration, oil, and moisture resistant |

| Connectivity | Relay outputs and analog output for DCS or PLC integration |

| Configuration | Adjustable alarm thresholds and frequency filters |

Product Applications

The 1900/27-02-00 Vibration Monitor is suitable for a wide range of industrial and critical applications:

-

Continuous vibration monitoring of turbines, compressors, generators, and pumps

-

Detection of imbalance, misalignment, bearing wear, and looseness in rotating machinery

-

Integration with DCS or PLC systems for machinery protection

-

Early warning and trip signaling to prevent catastrophic machinery failures

-

Condition monitoring during commissioning, routine inspections, and predictive maintenance

-

Retrofitting legacy machines for advanced vibration monitoring

-

Real-time monitoring in power plants, petrochemical, oil & gas, and manufacturing facilities

Product Advantages

High Accuracy: Provides precise measurement of vibration amplitude, velocity, and frequency.

Robust Construction: Resistant to shock, vibration, oil, and moisture for industrial reliability.

Sensor Flexibility: Compatible with proximity probes and accelerometers for versatile monitoring.

Configurable Alarms: Adjustable thresholds for alert, high vibration, and trip outputs.

Predictive Maintenance: Supports early detection of machinery faults to reduce downtime.

Easy Integration: Analog and relay outputs allow connection to DCS or PLC systems.

User-Friendly Interface: Analog meter and LED indicators provide clear visual feedback.

Extended Frequency Response: Supports detection of high-frequency vibrations for accurate diagnostics.

Frequently Asked Questions (FAQ)

What sensors are compatible with the 1900/27-02-00 monitor?

It supports proximity probes and accelerometers.

What is the measurement range of this monitor?

0–50 mm/s velocity or 0–100 mil displacement depending on configuration.

Can the alarm outputs be configured for multiple thresholds?

Yes, it supports adjustable thresholds for alert, high vibration, and trip signals.

What is the frequency response of this monitor?

5 Hz – 15 kHz.

Is the monitor suitable for high-humidity environments?

Yes, it operates reliably in 5% to 95% RH non-condensing conditions.

How does it communicate with DCS systems?

Through relay outputs and analog outputs compatible with standard DCS or PLC input modules.

Can it be used for both rotating and reciprocating machinery?

Yes, it is capable of monitoring vibration across various types of rotating equipment.

What temperature ranges are supported for operation?

0°C to 55°C operational, -20°C to 70°C storage.

Does the monitor provide visual indication of vibration status?

Yes, via analog meter and LED indicators.

Can this monitor be used for retrofitting existing machines?

Yes, it is ideal for retrofitting legacy machinery with advanced vibration monitoring capabilities.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...