Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

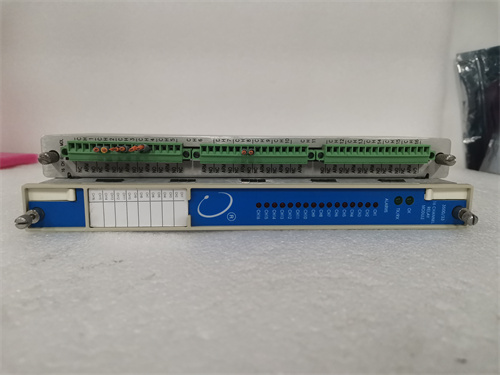

Bently Nevada 330103-02-04-30-01-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-02-04-30-01-00

Condition:3300 XL 8 mm Proximity Probe

Origin:USA

Cable length:3 m

Weight:0.969 kg

Views:24

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-02-04-30-01-00 is a vibration monitoring system designed for use in a wide range of industrial applications, such as turbines, compressors, and other rotating machinery. It is an integral part of the Bently Nevada 3300 Series, known for its high reliability, precise data collection, and real-time monitoring capabilities. The system continuously tracks machine conditions and alerts operators to potential issues, ensuring enhanced operational safety and performance. With a robust design and an extensive history in predictive maintenance, the 330103 model is highly regarded for its accuracy and longevity.

Product Specifications

Below is a table summarizing the key specifications of the Bently Nevada 330103-02-04-30-01-00:

| Specification | Value |

|---|---|

| Model | Bently Nevada 330103-02-04-30-01-00 |

| Cable length | 3 m |

| Weight | 0.969 kg |

| Voltage | 24 VDC (Nominal) |

| Current | 4-20 mA Output |

| Temperature Range | -20°C to 60°C (-4°F to 140°F) |

| Signal Output | Analog or Digital |

| Mounting Type | Panel-Mount |

| Compliance | CE, UL, RoHS |

Product Applications

The Bently Nevada 330103-02-04-30-01-00 vibration monitoring system is widely used across industries where machinery health monitoring is critical. Some common applications include:

Turbines – Monitoring vibration levels in steam, gas, and hydraulic turbines.

Compressors – Detecting faults such as imbalances or misalignments.

Motors and Generators – Ensuring early detection of mechanical failures.

Pumps – Detecting wear or degradation in pump components.

Fans – Monitoring the stability of industrial fans used in various processes.

Gearboxes – Preventing costly downtime by monitoring gear and bearing conditions.

Industrial HVAC Systems – Used for predictive maintenance of large-scale HVAC systems.

Product Advantages

Real-Time Monitoring: Provides continuous monitoring of machine vibration, allowing operators to quickly detect potential faults before they result in failure.

High Accuracy: Delivers precise data, helping to ensure optimal machine performance and preventing costly downtime.

Versatile Compatibility: Compatible with a wide variety of rotating machinery, making it suitable for diverse industries.

Cost-Effective: Reduces maintenance costs by detecting issues early, preventing catastrophic failures.

Reliable: With a proven track record in harsh industrial environments, the system is built to last and deliver reliable performance.

Ease of Integration: Can be integrated easily with existing control and monitoring systems.

FAQ(Frequently Asked Questions)

What type of machinery can the Bently Nevada 330103-02-04-30-01-00 be used for?

It is designed for monitoring the vibration of rotating machinery such as turbines, compressors, motors, and pumps.

What is the voltage requirement for this unit?

It operates on a 24 VDC nominal voltage.

Can this system be used in harsh environments?

Yes, it is designed to operate in harsh industrial environments, with a temperature range of -20°C to 60°C.

Is the system easy to install?

Yes, it is a panel-mount unit and is relatively simple to integrate with existing systems.

What is the typical output of this system?

The system provides an analog or digital output signal, which can be used to monitor vibration levels in real time.

Does the system have any certifications?

Yes, it is CE certified, UL listed, and RoHS compliant, ensuring it meets international safety and environmental standards.

What kind of maintenance is required for the system?

The system requires minimal maintenance; however, periodic checks should be conducted to ensure accurate data collection.

Can the system detect imbalance or misalignment?

Yes, the system can detect faults such as imbalances, misalignments, and other mechanical failures in rotating machinery.

Is there a warranty for the product?

Yes, Bently Nevada offers a warranty on their products; details of the warranty can be obtained from the supplier.

What industries use this product?

It is used in industries such as oil and gas, power generation, mining, and manufacturing.

Bently Nevada 330103-02-04-30-01-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-02-04-30-01-00

Condition:3300 XL 8 mm Proximity Probe

Origin:USA

Cable length:3 m

Weight:0.969 kg

Views:24

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-02-04-30-01-00 is a vibration monitoring system designed for use in a wide range of industrial applications, such as turbines, compressors, and other rotating machinery. It is an integral part of the Bently Nevada 3300 Series, known for its high reliability, precise data collection, and real-time monitoring capabilities. The system continuously tracks machine conditions and alerts operators to potential issues, ensuring enhanced operational safety and performance. With a robust design and an extensive history in predictive maintenance, the 330103 model is highly regarded for its accuracy and longevity.

Product Specifications

Below is a table summarizing the key specifications of the Bently Nevada 330103-02-04-30-01-00:

| Specification | Value |

|---|---|

| Model | Bently Nevada 330103-02-04-30-01-00 |

| Cable length | 3 m |

| Weight | 0.969 kg |

| Voltage | 24 VDC (Nominal) |

| Current | 4-20 mA Output |

| Temperature Range | -20°C to 60°C (-4°F to 140°F) |

| Signal Output | Analog or Digital |

| Mounting Type | Panel-Mount |

| Compliance | CE, UL, RoHS |

Product Applications

The Bently Nevada 330103-02-04-30-01-00 vibration monitoring system is widely used across industries where machinery health monitoring is critical. Some common applications include:

Turbines – Monitoring vibration levels in steam, gas, and hydraulic turbines.

Compressors – Detecting faults such as imbalances or misalignments.

Motors and Generators – Ensuring early detection of mechanical failures.

Pumps – Detecting wear or degradation in pump components.

Fans – Monitoring the stability of industrial fans used in various processes.

Gearboxes – Preventing costly downtime by monitoring gear and bearing conditions.

Industrial HVAC Systems – Used for predictive maintenance of large-scale HVAC systems.

Product Advantages

Real-Time Monitoring: Provides continuous monitoring of machine vibration, allowing operators to quickly detect potential faults before they result in failure.

High Accuracy: Delivers precise data, helping to ensure optimal machine performance and preventing costly downtime.

Versatile Compatibility: Compatible with a wide variety of rotating machinery, making it suitable for diverse industries.

Cost-Effective: Reduces maintenance costs by detecting issues early, preventing catastrophic failures.

Reliable: With a proven track record in harsh industrial environments, the system is built to last and deliver reliable performance.

Ease of Integration: Can be integrated easily with existing control and monitoring systems.

FAQ(Frequently Asked Questions)

What type of machinery can the Bently Nevada 330103-02-04-30-01-00 be used for?

It is designed for monitoring the vibration of rotating machinery such as turbines, compressors, motors, and pumps.

What is the voltage requirement for this unit?

It operates on a 24 VDC nominal voltage.

Can this system be used in harsh environments?

Yes, it is designed to operate in harsh industrial environments, with a temperature range of -20°C to 60°C.

Is the system easy to install?

Yes, it is a panel-mount unit and is relatively simple to integrate with existing systems.

What is the typical output of this system?

The system provides an analog or digital output signal, which can be used to monitor vibration levels in real time.

Does the system have any certifications?

Yes, it is CE certified, UL listed, and RoHS compliant, ensuring it meets international safety and environmental standards.

What kind of maintenance is required for the system?

The system requires minimal maintenance; however, periodic checks should be conducted to ensure accurate data collection.

Can the system detect imbalance or misalignment?

Yes, the system can detect faults such as imbalances, misalignments, and other mechanical failures in rotating machinery.

Is there a warranty for the product?

Yes, Bently Nevada offers a warranty on their products; details of the warranty can be obtained from the supplier.

What industries use this product?

It is used in industries such as oil and gas, power generation, mining, and manufacturing.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...