Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

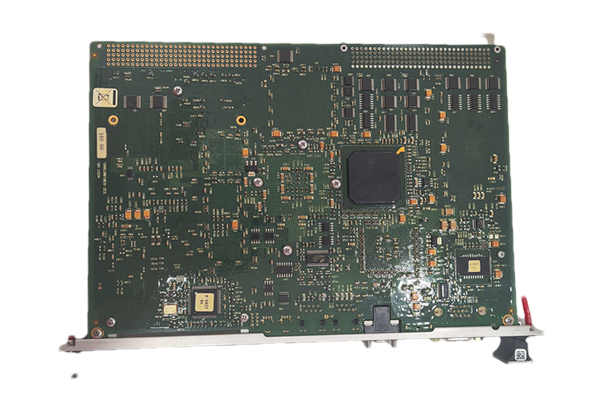

General Electric IS200VTURH1BMK6 VME Turbine Protection Board

Manufacturer:GE

Product Number:IS200VTURH1BMK6

Product Type:VME Turbine Protection Board

Origin:USA

Dimensions:340 x 220 x 25 mm

Weight:0.295 kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200VTURH1BMK6 VME Turbine Protection Board is an advanced module engineered for high-performance turbine protection within GE Mark VI and Mark VIe control systems. Designed with a rugged VME architecture, this board integrates real-time monitoring, sensor interfacing, and rapid protection logic to ensure the safety and operational integrity of gas and steam turbines in demanding industrial environments.

The IS200VTURH1BMK6 is specifically optimized to handle critical functions such as overspeed trip protection, vibration monitoring, and temperature detection. Its modular design allows seamless integration into existing control systems, while its diagnostic capabilities enable quick fault detection and maintenance. This makes it a crucial component for ensuring turbine reliability in power generation, oil & gas, and process automation industries.

Product Specifications

| Parameter | Details |

|---|---|

| Model | GE IS200VTURH1BMK6 |

| Type | VME Turbine Protection Board |

| System Compatibility | GE Mark VI / Mark VIe Control Systems |

| Communication Bus | VME backplane |

| Inputs | Multiple sensor inputs (vibration, speed, temperature) |

| Processing | Real-time digital signal processing |

| Protection Functions | Overspeed trip, vibration shutdown, temperature alarms |

| Redundancy | Supports dual and triple modular redundancy (TMR) |

| Diagnostics | Built-in self-test and fault detection |

| Power Supply | 28 VDC nominal |

| Operating Temperature | 0°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Compliance | CE, UL, IEC, RoHS |

| Dimensions (L x W x H) | 340 x 220 x 25 mm |

| Weight | 0.295 kg |

Product Applications

Turbine Protection: Provides critical overspeed and vibration protection for steam and gas turbines.

Power Generation Plants: Integral for turbine safety in thermal and combined-cycle power stations.

Oil & Gas Facilities: Protects turbine-driven compressors and pumps in upstream and downstream operations.

Industrial Turbomachinery: Used in rotating equipment requiring precise monitoring and rapid trip execution.

Process Automation Systems: Interfaces with GE Mark VI/VIe DCS for comprehensive turbine control.

Redundant Architectures: Ideal for fault-tolerant systems where high availability is critical.

Product Advantages

High-Speed Response: Millisecond-level protection for overspeed and vibration events.

Advanced Sensor Integration: Connects to multiple speed pickups, vibration probes, and temperature sensors.

Designed for Harsh Environments: Rugged industrial construction ensures reliable performance in demanding conditions.

TMR Support: Compatible with dual and triple modular redundancy for continuous operation.

Built-In Diagnostics: Real-time fault detection and self-test capabilities reduce downtime.

Optimized for Mark VI/VIe Systems: Seamless integration with GE turbine control platforms.

FAQ

What control systems is the IS200VTURH1BMK6 compatible with?

It is fully compatible with GE Mark VI and Mark VIe turbine control systems.

Does the board support redundant configurations?

Yes, it supports both dual and triple modular redundancy for mission-critical applications.

Can the IS200VTURH1BMK6 handle multiple sensor inputs?

It supports multiple channels for vibration, speed, and temperature sensors simultaneously.

What type of communication interface does it use?

The board uses a VME backplane for high-speed data exchange with the control system.

Is overspeed protection a built-in function of this board?

Yes, the board is specifically designed to provide real-time overspeed trip protection.

How does the board perform fault diagnostics?

It features built-in self-test capabilities and real-time fault monitoring functions.

Can this board integrate with turbine shutdown protocols?

Yes, it supports rapid trip execution and shutdown sequences during abnormal events.

What types of turbines can the IS200VTURH1BMK6 be used with?

It is suitable for both gas and steam turbines, as well as industrial rotating machinery.

Does it support temperature monitoring in addition to vibration and speed?

Yes, it can interface with RTDs and thermocouples for precise temperature monitoring.

What power supply does the IS200VTURH1BMK6 require?

The board operates on a nominal 28 VDC power supply for stable performance.

General Electric IS200VTURH1BMK6 VME Turbine Protection Board

Manufacturer:GE

Product Number:IS200VTURH1BMK6

Product Type:VME Turbine Protection Board

Origin:USA

Dimensions:340 x 220 x 25 mm

Weight:0.295 kg

Views:40

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200VTURH1BMK6 VME Turbine Protection Board is an advanced module engineered for high-performance turbine protection within GE Mark VI and Mark VIe control systems. Designed with a rugged VME architecture, this board integrates real-time monitoring, sensor interfacing, and rapid protection logic to ensure the safety and operational integrity of gas and steam turbines in demanding industrial environments.

The IS200VTURH1BMK6 is specifically optimized to handle critical functions such as overspeed trip protection, vibration monitoring, and temperature detection. Its modular design allows seamless integration into existing control systems, while its diagnostic capabilities enable quick fault detection and maintenance. This makes it a crucial component for ensuring turbine reliability in power generation, oil & gas, and process automation industries.

Product Specifications

| Parameter | Details |

|---|---|

| Model | GE IS200VTURH1BMK6 |

| Type | VME Turbine Protection Board |

| System Compatibility | GE Mark VI / Mark VIe Control Systems |

| Communication Bus | VME backplane |

| Inputs | Multiple sensor inputs (vibration, speed, temperature) |

| Processing | Real-time digital signal processing |

| Protection Functions | Overspeed trip, vibration shutdown, temperature alarms |

| Redundancy | Supports dual and triple modular redundancy (TMR) |

| Diagnostics | Built-in self-test and fault detection |

| Power Supply | 28 VDC nominal |

| Operating Temperature | 0°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Compliance | CE, UL, IEC, RoHS |

| Dimensions (L x W x H) | 340 x 220 x 25 mm |

| Weight | 0.295 kg |

Product Applications

Turbine Protection: Provides critical overspeed and vibration protection for steam and gas turbines.

Power Generation Plants: Integral for turbine safety in thermal and combined-cycle power stations.

Oil & Gas Facilities: Protects turbine-driven compressors and pumps in upstream and downstream operations.

Industrial Turbomachinery: Used in rotating equipment requiring precise monitoring and rapid trip execution.

Process Automation Systems: Interfaces with GE Mark VI/VIe DCS for comprehensive turbine control.

Redundant Architectures: Ideal for fault-tolerant systems where high availability is critical.

Product Advantages

High-Speed Response: Millisecond-level protection for overspeed and vibration events.

Advanced Sensor Integration: Connects to multiple speed pickups, vibration probes, and temperature sensors.

Designed for Harsh Environments: Rugged industrial construction ensures reliable performance in demanding conditions.

TMR Support: Compatible with dual and triple modular redundancy for continuous operation.

Built-In Diagnostics: Real-time fault detection and self-test capabilities reduce downtime.

Optimized for Mark VI/VIe Systems: Seamless integration with GE turbine control platforms.

FAQ

What control systems is the IS200VTURH1BMK6 compatible with?

It is fully compatible with GE Mark VI and Mark VIe turbine control systems.

Does the board support redundant configurations?

Yes, it supports both dual and triple modular redundancy for mission-critical applications.

Can the IS200VTURH1BMK6 handle multiple sensor inputs?

It supports multiple channels for vibration, speed, and temperature sensors simultaneously.

What type of communication interface does it use?

The board uses a VME backplane for high-speed data exchange with the control system.

Is overspeed protection a built-in function of this board?

Yes, the board is specifically designed to provide real-time overspeed trip protection.

How does the board perform fault diagnostics?

It features built-in self-test capabilities and real-time fault monitoring functions.

Can this board integrate with turbine shutdown protocols?

Yes, it supports rapid trip execution and shutdown sequences during abnormal events.

What types of turbines can the IS200VTURH1BMK6 be used with?

It is suitable for both gas and steam turbines, as well as industrial rotating machinery.

Does it support temperature monitoring in addition to vibration and speed?

Yes, it can interface with RTDs and thermocouples for precise temperature monitoring.

What power supply does the IS200VTURH1BMK6 require?

The board operates on a nominal 28 VDC power supply for stable performance.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...