Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

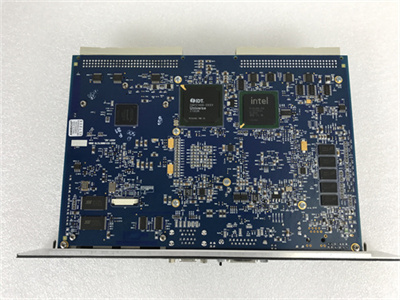

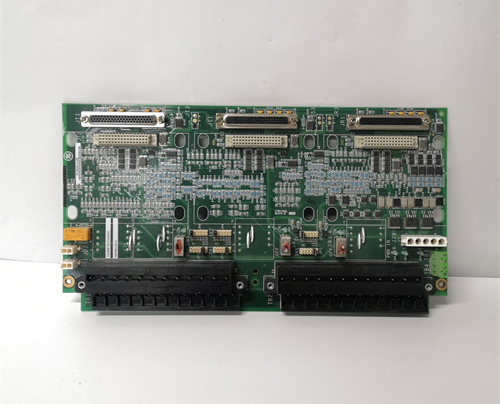

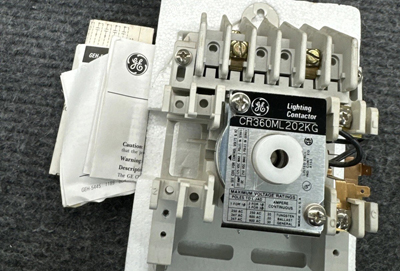

General Electric IS215VPWRH2AC Turbine Protection Plate

Manufacturer:GE

Product Number:IS215VPWRH2AC

Product Type:Turbine Protection Plate

Origin:USA

Dimensions:200 x 100 x 40 mm

Weight:0.75 kg

Views:20

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS215VPWRH2AC Turbine Protection Plate is a vital component in General Electric’s Mark VIe and related turbine control systems. It functions as a critical power interface and distribution module, providing secure and stable power connections to various system boards and field devices involved in turbine protection and control.

Designed with high-reliability architecture, the IS215VPWRH2AC ensures uninterrupted and conditioned power delivery to critical circuits, including safety relays, sensors, trip solenoids, and emergency shutdown components. The module’s robust construction and field-proven design make it indispensable for both new builds and retrofit applications in gas turbines, steam turbines, and industrial generator systems.

Whether for combined-cycle, peaking, or base-load generation plants, this protection plate contributes to high plant availability and system integrity under all operating conditions.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | GE IS215VPWRH2AC Turbine Protection Plate |

| Model Number | IS215VPWRH2AC |

| Series | GE Mark VIe / Mark VI Series |

| Function | Turbine Protection Power Distribution Plate |

| Input Voltage | 125 VDC nominal |

| Output Voltage | Multiple outputs (24 VDC, 28 VDC, 125 VDC pass-through) |

| Current Capacity | 5 A per output channel (varies by output) |

| Input Power | Up to 300 W |

| Protections | Overcurrent, Overvoltage, Reverse Polarity |

| Control Interface | Pluggable terminal block, fast disconnects |

| Monitoring Features | Fused protection with LED status indicators |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity Range | 5% to 95%, non-condensing |

| Shock / Vibration Resistance | IEC 60068 compliant |

| Mounting Type | Panel-mounted |

| Dimensions (H x W x D) | 200 x 100 x 40 mm |

| Weight | 0.75 kg |

| Certifications | CE, UL, CSA, ISO9001 |

Product Applications

The GE IS215VPWRH2AC is used in power plants and industrial facilities worldwide, offering enhanced power reliability and system protection in the following applications:

-

Provides stable DC power to sensors, trip solenoids, and turbine protection relays in both aero-derivative and frame-type gas turbines.

Steam Turbine Protection

Ensures the integrity of steam turbine trip and overspeed protection circuits.

Combined Cycle Plants

Supplies reliable DC distribution to multi-shaft turbine trains and auxiliary systems.

Generator Control Panels

Interfaces with generator circuit breaker controls, protective relays, and emergency stop systems.

Industrial Process Turbines

Protects mechanical drive turbines used in refineries, chemical plants, and pipeline compression.

Retrofitted Turbine Upgrades

Used in modernization projects to replace older relay-based power plates with advanced, fused, and monitored units.

Product Advantages

High-Reliability Architecture

Proven field performance in harsh turbine environments.

Integrated Protection Features

Built-in fusing, LED diagnostics, and current monitoring simplify maintenance and enhance protection.

Modular and Scalable

Can be easily integrated with existing Mark VIe and legacy systems.

Universal DC Input

Compatible with standard 125 VDC plant auxiliary systems.

Compact Form Factor

Saves panel space while providing high power density.

Wide Environmental Tolerance

Operates across wide temperature and humidity ranges, ensuring suitability for global installations.

Certified for Global Use

CE, UL, CSA, and ISO-certified design.

Field-Serviceable Design

Terminal blocks and fuse carriers designed for quick replacement and easy field service.

Frequently Asked Questions (FAQ)

What is the primary role of the GE IS215VPWRH2AC?

It distributes stable DC power to critical turbine protection circuits and control boards.

Is it compatible with the Mark VIe system?

Yes, it is fully compatible with GE Mark VIe and earlier Mark VI systems.

What input voltage does it require?

It operates from a nominal 125 VDC input.

What outputs does the module provide?

Provides 24 VDC, 28 VDC, and 125 VDC outputs with fused protection.

What is the rated current for each output?

Each channel can supply up to 5 A, depending on the configuration.

Does the plate include status indicators?

Yes, integrated LED indicators show fuse status and circuit health.

Can the module operate in high-humidity environments?

Yes, it is rated for 5% to 95% non-condensing humidity.

What certifications does this unit carry?

CE, UL, CSA, and ISO9001 certifications.

Is this module hot-swappable?

No, output channels are fused but require de-energization for replacement.

What types of turbines is this product used with?

It is used with gas turbines, steam turbines, combined cycle units, and industrial mechanical drive turbines.

General Electric IS215VPWRH2AC Turbine Protection Plate

Manufacturer:GE

Product Number:IS215VPWRH2AC

Product Type:Turbine Protection Plate

Origin:USA

Dimensions:200 x 100 x 40 mm

Weight:0.75 kg

Views:20

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS215VPWRH2AC Turbine Protection Plate is a vital component in General Electric’s Mark VIe and related turbine control systems. It functions as a critical power interface and distribution module, providing secure and stable power connections to various system boards and field devices involved in turbine protection and control.

Designed with high-reliability architecture, the IS215VPWRH2AC ensures uninterrupted and conditioned power delivery to critical circuits, including safety relays, sensors, trip solenoids, and emergency shutdown components. The module’s robust construction and field-proven design make it indispensable for both new builds and retrofit applications in gas turbines, steam turbines, and industrial generator systems.

Whether for combined-cycle, peaking, or base-load generation plants, this protection plate contributes to high plant availability and system integrity under all operating conditions.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | GE IS215VPWRH2AC Turbine Protection Plate |

| Model Number | IS215VPWRH2AC |

| Series | GE Mark VIe / Mark VI Series |

| Function | Turbine Protection Power Distribution Plate |

| Input Voltage | 125 VDC nominal |

| Output Voltage | Multiple outputs (24 VDC, 28 VDC, 125 VDC pass-through) |

| Current Capacity | 5 A per output channel (varies by output) |

| Input Power | Up to 300 W |

| Protections | Overcurrent, Overvoltage, Reverse Polarity |

| Control Interface | Pluggable terminal block, fast disconnects |

| Monitoring Features | Fused protection with LED status indicators |

| Operating Temperature Range | 0°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity Range | 5% to 95%, non-condensing |

| Shock / Vibration Resistance | IEC 60068 compliant |

| Mounting Type | Panel-mounted |

| Dimensions (H x W x D) | 200 x 100 x 40 mm |

| Weight | 0.75 kg |

| Certifications | CE, UL, CSA, ISO9001 |

Product Applications

The GE IS215VPWRH2AC is used in power plants and industrial facilities worldwide, offering enhanced power reliability and system protection in the following applications:

-

Provides stable DC power to sensors, trip solenoids, and turbine protection relays in both aero-derivative and frame-type gas turbines.

Steam Turbine Protection

Ensures the integrity of steam turbine trip and overspeed protection circuits.

Combined Cycle Plants

Supplies reliable DC distribution to multi-shaft turbine trains and auxiliary systems.

Generator Control Panels

Interfaces with generator circuit breaker controls, protective relays, and emergency stop systems.

Industrial Process Turbines

Protects mechanical drive turbines used in refineries, chemical plants, and pipeline compression.

Retrofitted Turbine Upgrades

Used in modernization projects to replace older relay-based power plates with advanced, fused, and monitored units.

Product Advantages

High-Reliability Architecture

Proven field performance in harsh turbine environments.

Integrated Protection Features

Built-in fusing, LED diagnostics, and current monitoring simplify maintenance and enhance protection.

Modular and Scalable

Can be easily integrated with existing Mark VIe and legacy systems.

Universal DC Input

Compatible with standard 125 VDC plant auxiliary systems.

Compact Form Factor

Saves panel space while providing high power density.

Wide Environmental Tolerance

Operates across wide temperature and humidity ranges, ensuring suitability for global installations.

Certified for Global Use

CE, UL, CSA, and ISO-certified design.

Field-Serviceable Design

Terminal blocks and fuse carriers designed for quick replacement and easy field service.

Frequently Asked Questions (FAQ)

What is the primary role of the GE IS215VPWRH2AC?

It distributes stable DC power to critical turbine protection circuits and control boards.

Is it compatible with the Mark VIe system?

Yes, it is fully compatible with GE Mark VIe and earlier Mark VI systems.

What input voltage does it require?

It operates from a nominal 125 VDC input.

What outputs does the module provide?

Provides 24 VDC, 28 VDC, and 125 VDC outputs with fused protection.

What is the rated current for each output?

Each channel can supply up to 5 A, depending on the configuration.

Does the plate include status indicators?

Yes, integrated LED indicators show fuse status and circuit health.

Can the module operate in high-humidity environments?

Yes, it is rated for 5% to 95% non-condensing humidity.

What certifications does this unit carry?

CE, UL, CSA, and ISO9001 certifications.

Is this module hot-swappable?

No, output channels are fused but require de-energization for replacement.

What types of turbines is this product used with?

It is used with gas turbines, steam turbines, combined cycle units, and industrial mechanical drive turbines.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...