Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

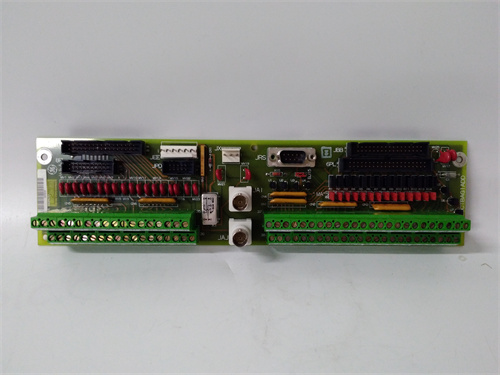

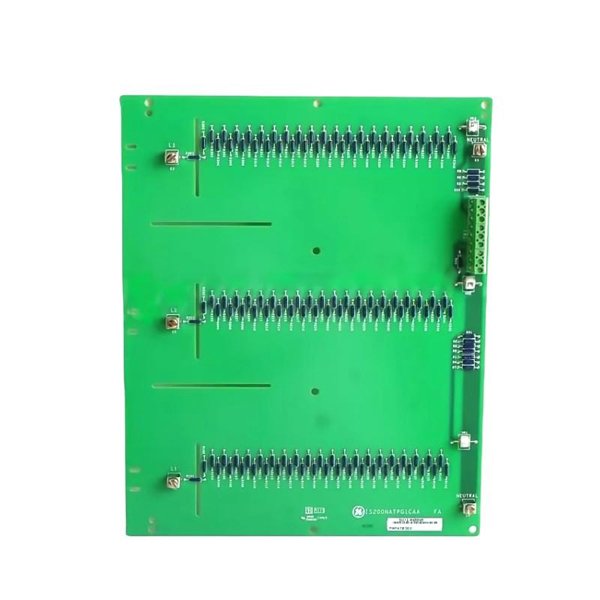

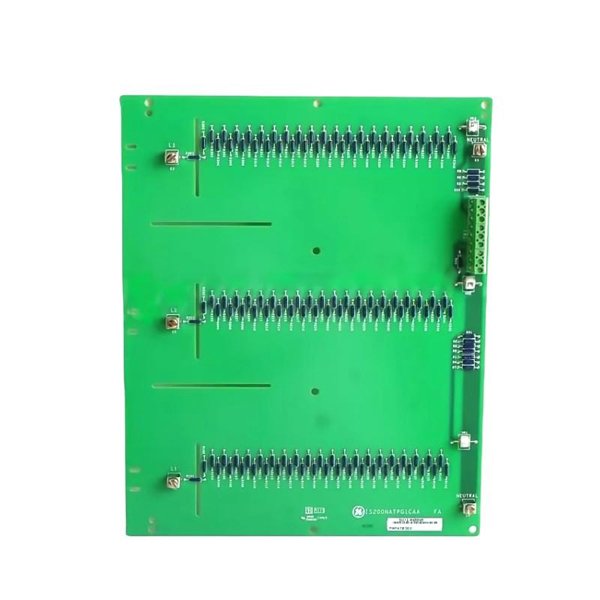

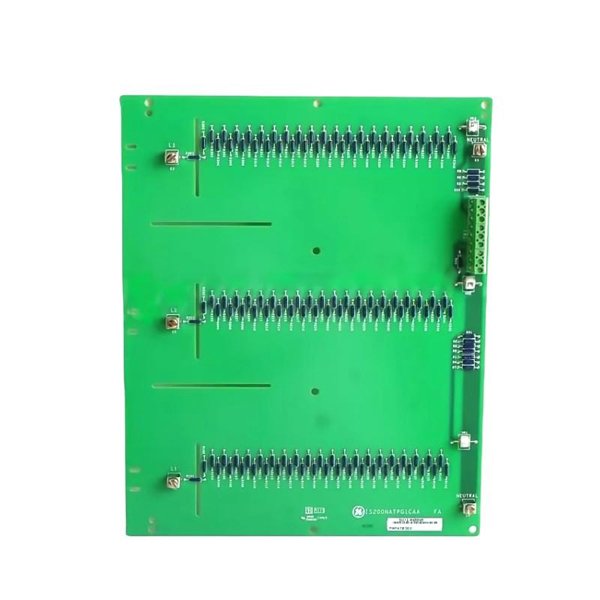

General Electric IS200NATPG1CAA Control Assembly Backplane

Manufacturer:GE

Product Number:IS200NATPG1CAA

Product Type:Control Assembly Backplane

Origin:USA

Dimensions:425 × 290 × 40 mm

Weight:0.5 kg

Views:18

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

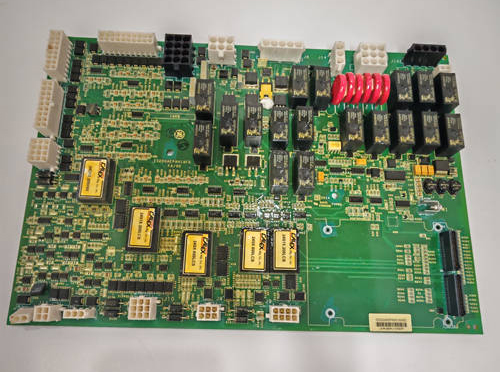

The GE IS200NATPG1CAA is a Control Assembly Backplane Module designed for use in GE Mark VI and Mark VIe control systems, specifically serving as a high-density backplane that enables communication and power distribution between multiple I/O, control, and interface modules. This backplane is essential for organizing and structurally supporting the installation of printed circuit boards (PCBs) within a control cabinet or VME chassis.

Engineered for reliable, real-time communication and synchronization, the IS200NATPG1CAA connects controllers to I/O modules, terminal boards, and other critical components. Its robust signal integrity design and fault-tolerant architecture ensure that control signals, analog data, and diagnostics flow seamlessly throughout the system.

The module plays a vital role in high-reliability industrial automation and turbine control environments, making it an indispensable part of GE’s distributed control infrastructure.

Product Specifications

| Parameter | Description |

|---|---|

| Model | IS200NATPG1CAA |

| Part Number | IS200NATPG1CAA |

| Module Type | Control Assembly Backplane |

| Function | Physical and electrical interface for system control modules |

| Signal Type | Digital, analog, control, and power bus |

| Slot Configuration | Supports multiple module slots (varies by application) |

| Supported Modules | VME CPU, IONet, TREG, TRLY, VCMI, DSPX, and others |

| Communication Bus | VME, IONet, Ethernet (through module interfaces) |

| Power Distribution | Supplies +5V, ±15V, and other required voltages to modules |

| Backplane Protocol | VME64 architecture compliant |

| Hot Swap Capability | Dependent on connected module configuration |

| Mounting Type | Rack-mounted in control cabinet |

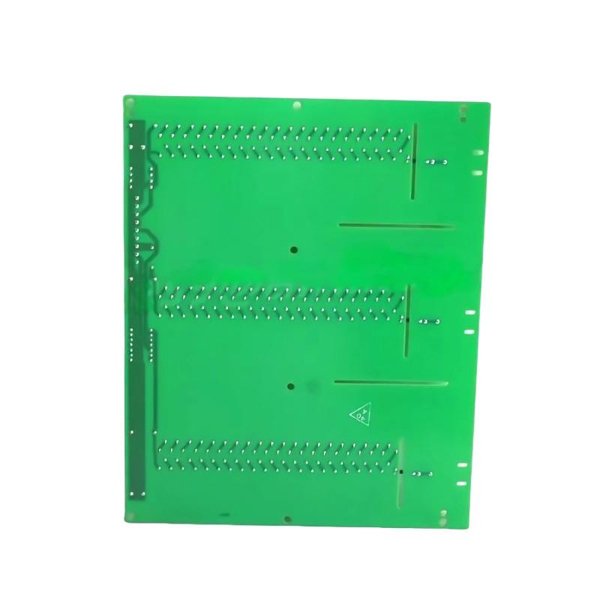

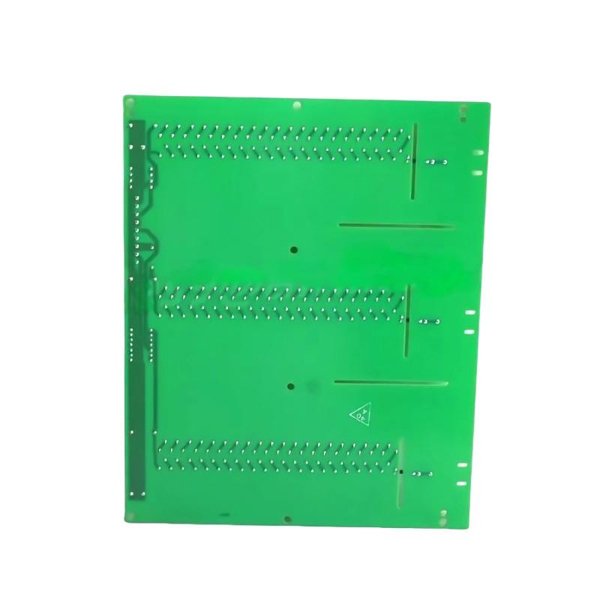

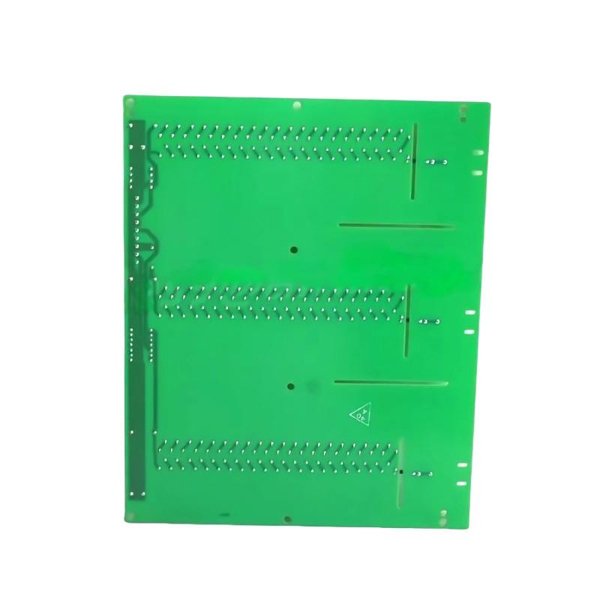

| Material | Multilayer PCB with reinforced fiberglass epoxy |

| Diagnostics | Passive component – no active diagnostics |

| System Compatibility | GE Mark VI, Mark VIe |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% RH non-condensing |

| Dimensions (W × H × D) | 425 × 290 × 40 mm |

| Weight | 0.5 kg |

| Certifications | CE, UL, CSA |

Product Applications

The GE IS200NATPG1CAA is deployed in industrial automation and turbine control systems, where high-speed backplane communication and modular system design are essential. Its applications include:

Gas and Steam Turbine Control Systems – Providing the physical foundation for controller and I/O module interconnection in critical energy applications.

Balance of Plant (BoP) Systems – Supporting subsystems such as pumps, fans, and compressors through integrated control.

Industrial Automation Panels – Enabling communication between logic processors, signal conditioners, and relay modules.

Power Generation Plants – Serving as the structural and electrical backbone for centralized turbine control platforms.

SCADA and DCS Architectures – Offering streamlined wiring and signal routing for distributed control elements.

Marine and Naval Applications – Supporting real-time control in ruggedized environments where vibration and temperature stability are essential.

Product Advantages

Modular Flexibility: Allows system integrators to customize configurations with various I/O and controller cards.

High-Speed Signal Integrity: Designed for use with VME64 architecture to ensure low-latency, noise-resistant communication.

Centralized Power Distribution: Efficiently supplies required voltages to all mounted modules, reducing wiring complexity.

Structural Integration: Simplifies physical installation of multiple circuit boards into a single system chassis.

GE Mark VI/VIe Compatibility: Seamlessly integrates with standard GE control platforms for easy deployment and expansion.

Reliable Connectivity: Ensures proper signal routing between all functional modules, minimizing downtime risks.

Industrial Durability: Manufactured using high-grade PCB material suitable for harsh operational conditions.

Simplified Maintenance: Provides clear modular layout for service access and upgrades.

Frequently Asked Questions (FAQ)

Which GE systems are compatible with the IS200NATPG1CAA backplane?

It is designed for GE Mark VI and Mark VIe control platforms.

Does the backplane support VME communication architecture?

Yes, it supports VME64 standard architecture and is compatible with GE VME-based modules.

Can analog and digital signals be routed simultaneously through this backplane?

Yes, it supports both analog and digital signal types for integrated system operations.

Is this module hot-swappable?

The backplane itself is passive; hot-swapping depends on the active modules connected to it.

Does the backplane include embedded diagnostics?

No, the backplane is a passive component and does not include onboard diagnostics.

How is power supplied to modules via the backplane?

Power is distributed through integrated bus lines that deliver multiple voltage rails.

What types of modules can be mounted on this backplane?

Common modules include VCMI, DSPX, TRLY, TREG, and VME CPU cards.

Can it be used in redundant system configurations?

Yes, it supports systems designed with controller and I/O redundancy.

Is shielding required for use in high-EMI environments?

Shielding is recommended for high-noise areas but the board design supports EMI-resistant communication.

What is the typical wiring method used with this backplane?

Ribbon cable connectors and pin headers are typically used for module interconnection.

General Electric IS200NATPG1CAA Control Assembly Backplane

Manufacturer:GE

Product Number:IS200NATPG1CAA

Product Type:Control Assembly Backplane

Origin:USA

Dimensions:425 × 290 × 40 mm

Weight:0.5 kg

Views:18

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IS200NATPG1CAA is a Control Assembly Backplane Module designed for use in GE Mark VI and Mark VIe control systems, specifically serving as a high-density backplane that enables communication and power distribution between multiple I/O, control, and interface modules. This backplane is essential for organizing and structurally supporting the installation of printed circuit boards (PCBs) within a control cabinet or VME chassis.

Engineered for reliable, real-time communication and synchronization, the IS200NATPG1CAA connects controllers to I/O modules, terminal boards, and other critical components. Its robust signal integrity design and fault-tolerant architecture ensure that control signals, analog data, and diagnostics flow seamlessly throughout the system.

The module plays a vital role in high-reliability industrial automation and turbine control environments, making it an indispensable part of GE’s distributed control infrastructure.

Product Specifications

| Parameter | Description |

|---|---|

| Model | IS200NATPG1CAA |

| Part Number | IS200NATPG1CAA |

| Module Type | Control Assembly Backplane |

| Function | Physical and electrical interface for system control modules |

| Signal Type | Digital, analog, control, and power bus |

| Slot Configuration | Supports multiple module slots (varies by application) |

| Supported Modules | VME CPU, IONet, TREG, TRLY, VCMI, DSPX, and others |

| Communication Bus | VME, IONet, Ethernet (through module interfaces) |

| Power Distribution | Supplies +5V, ±15V, and other required voltages to modules |

| Backplane Protocol | VME64 architecture compliant |

| Hot Swap Capability | Dependent on connected module configuration |

| Mounting Type | Rack-mounted in control cabinet |

| Material | Multilayer PCB with reinforced fiberglass epoxy |

| Diagnostics | Passive component – no active diagnostics |

| System Compatibility | GE Mark VI, Mark VIe |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% RH non-condensing |

| Dimensions (W × H × D) | 425 × 290 × 40 mm |

| Weight | 0.5 kg |

| Certifications | CE, UL, CSA |

Product Applications

The GE IS200NATPG1CAA is deployed in industrial automation and turbine control systems, where high-speed backplane communication and modular system design are essential. Its applications include:

Gas and Steam Turbine Control Systems – Providing the physical foundation for controller and I/O module interconnection in critical energy applications.

Balance of Plant (BoP) Systems – Supporting subsystems such as pumps, fans, and compressors through integrated control.

Industrial Automation Panels – Enabling communication between logic processors, signal conditioners, and relay modules.

Power Generation Plants – Serving as the structural and electrical backbone for centralized turbine control platforms.

SCADA and DCS Architectures – Offering streamlined wiring and signal routing for distributed control elements.

Marine and Naval Applications – Supporting real-time control in ruggedized environments where vibration and temperature stability are essential.

Product Advantages

Modular Flexibility: Allows system integrators to customize configurations with various I/O and controller cards.

High-Speed Signal Integrity: Designed for use with VME64 architecture to ensure low-latency, noise-resistant communication.

Centralized Power Distribution: Efficiently supplies required voltages to all mounted modules, reducing wiring complexity.

Structural Integration: Simplifies physical installation of multiple circuit boards into a single system chassis.

GE Mark VI/VIe Compatibility: Seamlessly integrates with standard GE control platforms for easy deployment and expansion.

Reliable Connectivity: Ensures proper signal routing between all functional modules, minimizing downtime risks.

Industrial Durability: Manufactured using high-grade PCB material suitable for harsh operational conditions.

Simplified Maintenance: Provides clear modular layout for service access and upgrades.

Frequently Asked Questions (FAQ)

Which GE systems are compatible with the IS200NATPG1CAA backplane?

It is designed for GE Mark VI and Mark VIe control platforms.

Does the backplane support VME communication architecture?

Yes, it supports VME64 standard architecture and is compatible with GE VME-based modules.

Can analog and digital signals be routed simultaneously through this backplane?

Yes, it supports both analog and digital signal types for integrated system operations.

Is this module hot-swappable?

The backplane itself is passive; hot-swapping depends on the active modules connected to it.

Does the backplane include embedded diagnostics?

No, the backplane is a passive component and does not include onboard diagnostics.

How is power supplied to modules via the backplane?

Power is distributed through integrated bus lines that deliver multiple voltage rails.

What types of modules can be mounted on this backplane?

Common modules include VCMI, DSPX, TRLY, TREG, and VME CPU cards.

Can it be used in redundant system configurations?

Yes, it supports systems designed with controller and I/O redundancy.

Is shielding required for use in high-EMI environments?

Shielding is recommended for high-noise areas but the board design supports EMI-resistant communication.

What is the typical wiring method used with this backplane?

Ribbon cable connectors and pin headers are typically used for module interconnection.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...