Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

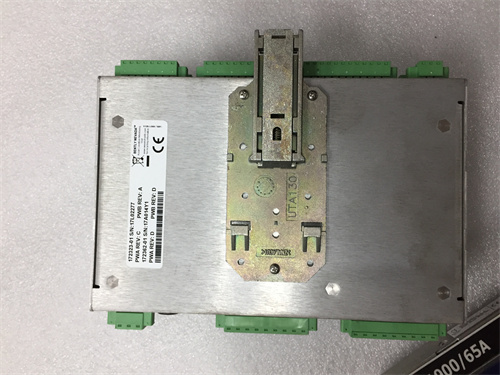

Bently Nevada 3300/16-03-01-01-00-00-00 Dual Vibration Monitor

Brand:Bently Nevada

Model Number:3300/16-03-01-01-00-00-00

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:5.1 cm x 20.3 cm x 33.0 cm

Weight:1.4 kg

Price:USD59

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/16-03-01-01-00-00-00 is designed for dual vibration and gap monitoring. It continuously measures and monitors two independent channels of radial vibration and average shaft position (gap). The monitor supports inputs from two proximity probe/Proximitor systems.

Key Features

- Continuous Monitoring: The 3300/16 provides real-time data for both vibration and gap measurements, ensuring effective condition monitoring and diagnostics.

- Dual Vibration Channels: This monitor measures two separate channels of radial vibration. It detects both horizontal and vertical vibration.

- Gap Measurement: It also measures average shaft position (gap), which is crucial for monitoring machine alignment and preventing damage.

- Proximity Probe Compatibility: The 3300/16 is compatible with various proximity probes. This versatility suits different application needs.

- Alarm Functions: Configure the monitor to trigger alarms when vibration or gap levels exceed preset thresholds. This feature alerts operators to potential issues.

- Data Logging: The monitor logs vibration and gap data for further analysis and trend tracking.

Applications

The Bently Nevada 3300/16 finds use in various industrial applications, such as:

- Rotating Machinery: It monitors turbines, pumps, fans, compressors, and other rotating equipment.

- Critical Processes: Use it in applications where machine downtime or failure can significantly impact operations.

- Predictive Maintenance: The monitor helps in predicting potential failures, enabling proactive maintenance and reducing downtime.

Bently Nevada 3300/16-03-01-01-00-00-00 Dual Vibration Monitor

Brand:Bently Nevada

Model Number:3300/16-03-01-01-00-00-00

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:5.1 cm x 20.3 cm x 33.0 cm

Weight:1.4 kg

Price:USD59

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 3300/16-03-01-01-00-00-00 is designed for dual vibration and gap monitoring. It continuously measures and monitors two independent channels of radial vibration and average shaft position (gap). The monitor supports inputs from two proximity probe/Proximitor systems.

Key Features

- Continuous Monitoring: The 3300/16 provides real-time data for both vibration and gap measurements, ensuring effective condition monitoring and diagnostics.

- Dual Vibration Channels: This monitor measures two separate channels of radial vibration. It detects both horizontal and vertical vibration.

- Gap Measurement: It also measures average shaft position (gap), which is crucial for monitoring machine alignment and preventing damage.

- Proximity Probe Compatibility: The 3300/16 is compatible with various proximity probes. This versatility suits different application needs.

- Alarm Functions: Configure the monitor to trigger alarms when vibration or gap levels exceed preset thresholds. This feature alerts operators to potential issues.

- Data Logging: The monitor logs vibration and gap data for further analysis and trend tracking.

Applications

The Bently Nevada 3300/16 finds use in various industrial applications, such as:

- Rotating Machinery: It monitors turbines, pumps, fans, compressors, and other rotating equipment.

- Critical Processes: Use it in applications where machine downtime or failure can significantly impact operations.

- Predictive Maintenance: The monitor helps in predicting potential failures, enabling proactive maintenance and reducing downtime.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...