Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

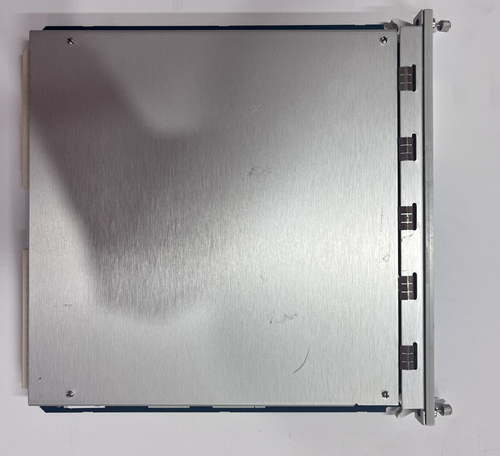

Bently Nevada 330880-28-25-061-01-02 PROXPAC XL Proximity Sensors

Manufacturer:Bently Nevada

Product Number:330880-28-25-061-01-02

Product Type:PROXPAC XL Proximity Sensors

Origin:USA

Dimensions:91.4 x 144.8 mm

Weight :1.44 kg

Views:5

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330880-28-25-061-01-02 PROXPAC XL Proximity Sensor is a high-performance industrial sensor designed for precise monitoring of shaft position and vibration in critical rotating machinery. Part of the PROXPAC XL series, this sensor provides highly accurate, reliable, and repeatable measurements, making it ideal for integration into vibration monitoring and protection systems. With robust construction and advanced sensing technology, it ensures stable performance even in harsh operating environments.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330880-28-25-061-01-02 |

| Sensor Type | Proximity / Eddy Current Sensor |

| Series | PROXPAC XL |

| Measurement Range | ±0.25 inches (±6.35 mm) typical |

| Frequency Response | 0–10 kHz |

| Output Type | AC Voltage / Differential |

| Excitation Voltage | 3–8 V rms |

| Temperature Range | -40°C to +120°C |

| Protection Class | IP67 |

| Connector Type | 6-pin or 4-pin (depending on configuration) |

| Cable Length | Standard 2 meters, customizable |

| Dimensions | 91.4 x 144.8 mm |

| Weight | 1.44 kg |

| Housing Material | Stainless steel |

| Mounting Type | Flanged / Threaded |

| Compatibility | 3300 XL Proximity System |

Product Applications

Rotating Machinery Monitoring: Shaft vibration and position monitoring in turbines, compressors, pumps, and generators.

Predictive Maintenance Systems: Provides data for condition-based maintenance and early fault detection.

Protection Systems: Integration into machinery protection systems for trip or alarm functions.

Industrial Plants: Power generation, petrochemical, oil & gas, and other heavy industries requiring continuous machinery monitoring.

High-Precision Monitoring: Suitable for critical machines where tight vibration and displacement tolerances are required.

Product Advantages

High Accuracy: Delivers precise displacement measurements with minimal drift over time.

Robust Design: Resistant to vibration, shock, and harsh environmental conditions.

Wide Frequency Range: Captures both low- and high-frequency vibration components.

Easy Integration: Fully compatible with the PROXPAC XL system, facilitating quick installation.

Reliable Performance: Ensures long-term operational stability even in demanding industrial conditions.

Flexible Mounting: Supports multiple mounting options and cable configurations.

FAQ

Q1: What is the standard output signal of this sensor?

A1: The sensor provides an AC voltage output proportional to shaft displacement, compatible with 3300 XL Proximity System electronics.

Q2: What is the operating frequency range of this sensor?

A2: The sensor has a frequency response of 0–10 kHz.

Q3: Can this sensor operate in high-temperature environments?

A3: Yes, it supports a temperature range from -40°C to +120°C.

Q4: Is this sensor compatible with older 3300 series systems?

A4: It is designed primarily for 3300 XL systems; compatibility with older 3300 systems may require verification.

Q5: What type of connection does the sensor use?

A5: The sensor uses a 6-pin or 4-pin connector depending on the configuration.

Q6: What protection level does this sensor provide against dust and moisture?

A6: It has an IP67 protection rating.

Q7: Can the sensor handle mechanical shock and vibration?

A7: Yes, it is designed for high vibration and shock environments typical in industrial machinery.

Q8: What is the typical measurement range?

A8: The standard measurement range is ±0.25 inches (±6.35 mm).

Q9: Does the sensor require calibration before installation?

A9: Factory calibration is provided; field verification may be recommended after installation.

Q10: Can the cable length be customized?

A10: Yes, standard cable length is 1 meters, and custom lengths can be requested.

Bently Nevada 330880-28-25-061-01-02 PROXPAC XL Proximity Sensors

Manufacturer:Bently Nevada

Product Number:330880-28-25-061-01-02

Product Type:PROXPAC XL Proximity Sensors

Origin:USA

Dimensions:91.4 x 144.8 mm

Weight :1.44 kg

Views:5

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330880-28-25-061-01-02 PROXPAC XL Proximity Sensor is a high-performance industrial sensor designed for precise monitoring of shaft position and vibration in critical rotating machinery. Part of the PROXPAC XL series, this sensor provides highly accurate, reliable, and repeatable measurements, making it ideal for integration into vibration monitoring and protection systems. With robust construction and advanced sensing technology, it ensures stable performance even in harsh operating environments.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330880-28-25-061-01-02 |

| Sensor Type | Proximity / Eddy Current Sensor |

| Series | PROXPAC XL |

| Measurement Range | ±0.25 inches (±6.35 mm) typical |

| Frequency Response | 0–10 kHz |

| Output Type | AC Voltage / Differential |

| Excitation Voltage | 3–8 V rms |

| Temperature Range | -40°C to +120°C |

| Protection Class | IP67 |

| Connector Type | 6-pin or 4-pin (depending on configuration) |

| Cable Length | Standard 2 meters, customizable |

| Dimensions | 91.4 x 144.8 mm |

| Weight | 1.44 kg |

| Housing Material | Stainless steel |

| Mounting Type | Flanged / Threaded |

| Compatibility | 3300 XL Proximity System |

Product Applications

Rotating Machinery Monitoring: Shaft vibration and position monitoring in turbines, compressors, pumps, and generators.

Predictive Maintenance Systems: Provides data for condition-based maintenance and early fault detection.

Protection Systems: Integration into machinery protection systems for trip or alarm functions.

Industrial Plants: Power generation, petrochemical, oil & gas, and other heavy industries requiring continuous machinery monitoring.

High-Precision Monitoring: Suitable for critical machines where tight vibration and displacement tolerances are required.

Product Advantages

High Accuracy: Delivers precise displacement measurements with minimal drift over time.

Robust Design: Resistant to vibration, shock, and harsh environmental conditions.

Wide Frequency Range: Captures both low- and high-frequency vibration components.

Easy Integration: Fully compatible with the PROXPAC XL system, facilitating quick installation.

Reliable Performance: Ensures long-term operational stability even in demanding industrial conditions.

Flexible Mounting: Supports multiple mounting options and cable configurations.

FAQ

Q1: What is the standard output signal of this sensor?

A1: The sensor provides an AC voltage output proportional to shaft displacement, compatible with 3300 XL Proximity System electronics.

Q2: What is the operating frequency range of this sensor?

A2: The sensor has a frequency response of 0–10 kHz.

Q3: Can this sensor operate in high-temperature environments?

A3: Yes, it supports a temperature range from -40°C to +120°C.

Q4: Is this sensor compatible with older 3300 series systems?

A4: It is designed primarily for 3300 XL systems; compatibility with older 3300 systems may require verification.

Q5: What type of connection does the sensor use?

A5: The sensor uses a 6-pin or 4-pin connector depending on the configuration.

Q6: What protection level does this sensor provide against dust and moisture?

A6: It has an IP67 protection rating.

Q7: Can the sensor handle mechanical shock and vibration?

A7: Yes, it is designed for high vibration and shock environments typical in industrial machinery.

Q8: What is the typical measurement range?

A8: The standard measurement range is ±0.25 inches (±6.35 mm).

Q9: Does the sensor require calibration before installation?

A9: Factory calibration is provided; field verification may be recommended after installation.

Q10: Can the cable length be customized?

A10: Yes, standard cable length is 1 meters, and custom lengths can be requested.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...