Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

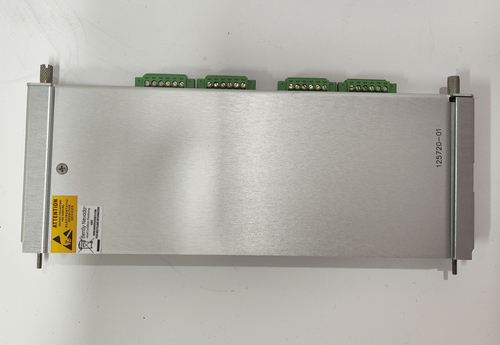

Bently Nevada 330104-03-06-05-02-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-03-06-05-02-00

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Dimensions:Total Length : 0.5 meter

Weight:0.161kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-03-06-05-02-00 proximity probe is a key component of the 3300 XL family of sensors, engineered to provide precise non-contact measurement of shaft vibration and position for industrial rotating machinery. Using advanced eddy current technology, the probe delivers highly accurate displacement signals essential for condition monitoring and machinery protection systems.

Designed for harsh industrial environments, this model features a ruggedized probe body, hermetic sealing for contaminant protection, and an integral coaxial cable. It ensures seamless compatibility with Bently Nevada 3300 XL Proximitor sensors and extension cables, making it ideal for predictive maintenance in power generation, oil & gas, petrochemical, and heavy manufacturing sectors.

Key Features

-

Non-contact eddy current sensing technology for high precision

-

Integral coaxial cable with robust shielding for noise immunity

-

Threaded probe body (3/8-24 UNF) for reliable mounting

-

Hermetically sealed probe tip to resist moisture and contaminants

-

Wide operating temperature range suitable for extreme conditions

-

Compatible with 3300 XL Proximitor sensors and extension cables

-

High resistance to shock and vibration

-

Meets EMC standards (IEC 61000-6-2 and IEC 61000-6-4)

-

Compact and lightweight design

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330104-03-06-05-02-00 |

| Series | 3300 XL 8 mm |

| Sensing Principle | Eddy current (non-contact) |

| Target Material | Conductive metals (e.g., 4140 steel) |

| Linear Range | 2 mm (80 mils) |

| System Accuracy | ±0.07 mm (±2.8 mils) within linear range |

| Output Voltage | -200 mV/mil (nominal) |

| Power Supply | Via 3300 XL Proximitor Sensor |

| Connector Type | Male Microdot coaxial |

| Cable Length | 0.5 meters |

| Thread Size | 3/8-24 UNF-2A |

| Mounting Method | Threaded probe body |

| Environmental Sealing | Hermetically sealed probe tip |

| Operating Temperature Range | -35°C to +177°C (-31°F to +351°F) |

| Shock Survivability | 5000 g peak |

| Vibration Survivability | 20 g, 10–2000 Hz sinusoidal |

| EMC Compliance | IEC 61000-6-2, IEC 61000-6-4 |

| Ingress Protection | IP67 |

| Dimensions | Total Length : 0.5 meter |

| Weight | 0.161 kg |

Industry Applications

Power Generation: Monitoring turbines and generators for vibration and shaft displacement

Oil & Gas: Condition monitoring of compressors, pumps, and drilling equipment

Petrochemical: Refinery rotating machinery protection

Steel & Mining: Mills, crushers, and motor shaft vibration analysis

Marine & Offshore: Propulsion system and auxiliary machinery monitoring

Pulp & Paper: Rollers and rotary machine vibration measurement

General Industrial Machinery: Equipment requiring precise shaft position and vibration sensing

Product Advantages

Accurate Measurement: Delivers precise vibration and shaft position data to support predictive maintenance

Durable Construction: Hermetically sealed and rugged design for long service life in harsh environments

System Compatibility: Designed for use with Bently Nevada 3300 XL system components

EMC Resistant: Maintains signal integrity in electrically noisy environments

Compact and Lightweight: Easy to install in confined spaces without sacrificing performance

Low Maintenance: Factory calibrated for minimal servicing

Wide Temperature Operation: Reliable from sub-zero to high temperatures

Shock and Vibration Resistant: Tested to withstand severe mechanical stresses

Industry Proven: Trusted worldwide for machinery health monitoring

Cost-Efficient: Helps reduce unplanned downtime and maintenance costs

Frequently Asked Questions (FAQ)

What does this proximity probe measure?

It measures shaft vibration and displacement non-contact via eddy current sensing.

Is the cable integral?

Yes, it includes a 0.6-meter integral coaxial cable.

What is the operating temperature range?

From -35°C to +177°C (-31°F to +351°F).

What is the linear range of measurement?

2 mm (80 mils).

How is the probe mounted?

With a 3/8-24 UNF threaded body.

Is it compatible with other systems?

It is designed specifically for the Bently Nevada 3300 XL system.

Does it require calibration?

Factory calibrated; typically does not require field recalibration.

Is it suitable for hazardous environments?

Depends on system certifications; the probe itself is rugged.

What materials can it detect?

Conductive metallic targets, usually steel.

What is its approximate weight?

About 0.161 kg.

Bently Nevada 330104-03-06-05-02-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330104-03-06-05-02-00

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Dimensions:Total Length : 0.5 meter

Weight:0.161kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330104-03-06-05-02-00 proximity probe is a key component of the 3300 XL family of sensors, engineered to provide precise non-contact measurement of shaft vibration and position for industrial rotating machinery. Using advanced eddy current technology, the probe delivers highly accurate displacement signals essential for condition monitoring and machinery protection systems.

Designed for harsh industrial environments, this model features a ruggedized probe body, hermetic sealing for contaminant protection, and an integral coaxial cable. It ensures seamless compatibility with Bently Nevada 3300 XL Proximitor sensors and extension cables, making it ideal for predictive maintenance in power generation, oil & gas, petrochemical, and heavy manufacturing sectors.

Key Features

-

Non-contact eddy current sensing technology for high precision

-

Integral coaxial cable with robust shielding for noise immunity

-

Threaded probe body (3/8-24 UNF) for reliable mounting

-

Hermetically sealed probe tip to resist moisture and contaminants

-

Wide operating temperature range suitable for extreme conditions

-

Compatible with 3300 XL Proximitor sensors and extension cables

-

High resistance to shock and vibration

-

Meets EMC standards (IEC 61000-6-2 and IEC 61000-6-4)

-

Compact and lightweight design

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 330104-03-06-05-02-00 |

| Series | 3300 XL 8 mm |

| Sensing Principle | Eddy current (non-contact) |

| Target Material | Conductive metals (e.g., 4140 steel) |

| Linear Range | 2 mm (80 mils) |

| System Accuracy | ±0.07 mm (±2.8 mils) within linear range |

| Output Voltage | -200 mV/mil (nominal) |

| Power Supply | Via 3300 XL Proximitor Sensor |

| Connector Type | Male Microdot coaxial |

| Cable Length | 0.5 meters |

| Thread Size | 3/8-24 UNF-2A |

| Mounting Method | Threaded probe body |

| Environmental Sealing | Hermetically sealed probe tip |

| Operating Temperature Range | -35°C to +177°C (-31°F to +351°F) |

| Shock Survivability | 5000 g peak |

| Vibration Survivability | 20 g, 10–2000 Hz sinusoidal |

| EMC Compliance | IEC 61000-6-2, IEC 61000-6-4 |

| Ingress Protection | IP67 |

| Dimensions | Total Length : 0.5 meter |

| Weight | 0.161 kg |

Industry Applications

Power Generation: Monitoring turbines and generators for vibration and shaft displacement

Oil & Gas: Condition monitoring of compressors, pumps, and drilling equipment

Petrochemical: Refinery rotating machinery protection

Steel & Mining: Mills, crushers, and motor shaft vibration analysis

Marine & Offshore: Propulsion system and auxiliary machinery monitoring

Pulp & Paper: Rollers and rotary machine vibration measurement

General Industrial Machinery: Equipment requiring precise shaft position and vibration sensing

Product Advantages

Accurate Measurement: Delivers precise vibration and shaft position data to support predictive maintenance

Durable Construction: Hermetically sealed and rugged design for long service life in harsh environments

System Compatibility: Designed for use with Bently Nevada 3300 XL system components

EMC Resistant: Maintains signal integrity in electrically noisy environments

Compact and Lightweight: Easy to install in confined spaces without sacrificing performance

Low Maintenance: Factory calibrated for minimal servicing

Wide Temperature Operation: Reliable from sub-zero to high temperatures

Shock and Vibration Resistant: Tested to withstand severe mechanical stresses

Industry Proven: Trusted worldwide for machinery health monitoring

Cost-Efficient: Helps reduce unplanned downtime and maintenance costs

Frequently Asked Questions (FAQ)

What does this proximity probe measure?

It measures shaft vibration and displacement non-contact via eddy current sensing.

Is the cable integral?

Yes, it includes a 0.6-meter integral coaxial cable.

What is the operating temperature range?

From -35°C to +177°C (-31°F to +351°F).

What is the linear range of measurement?

2 mm (80 mils).

How is the probe mounted?

With a 3/8-24 UNF threaded body.

Is it compatible with other systems?

It is designed specifically for the Bently Nevada 3300 XL system.

Does it require calibration?

Factory calibrated; typically does not require field recalibration.

Is it suitable for hazardous environments?

Depends on system certifications; the probe itself is rugged.

What materials can it detect?

Conductive metallic targets, usually steel.

What is its approximate weight?

About 0.161 kg.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...