Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

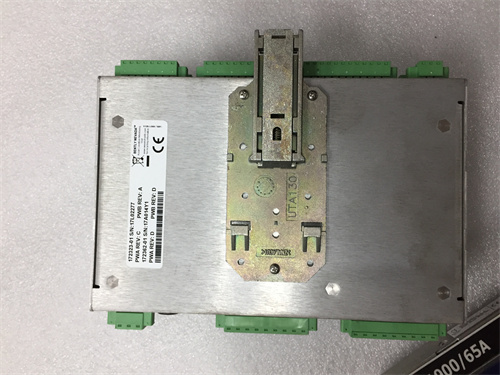

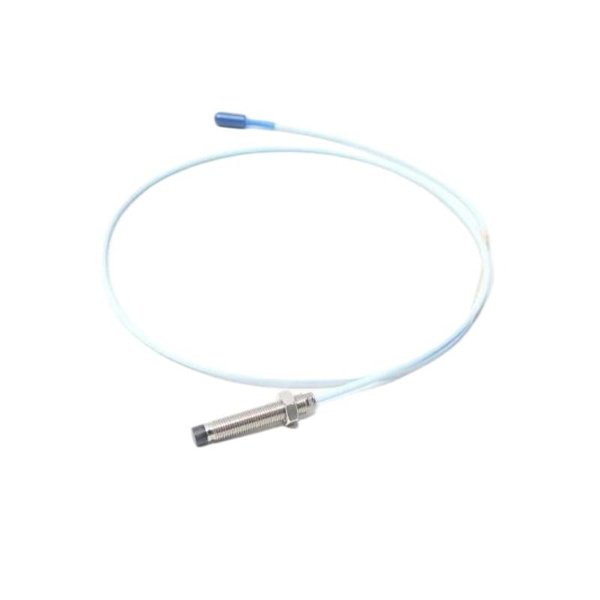

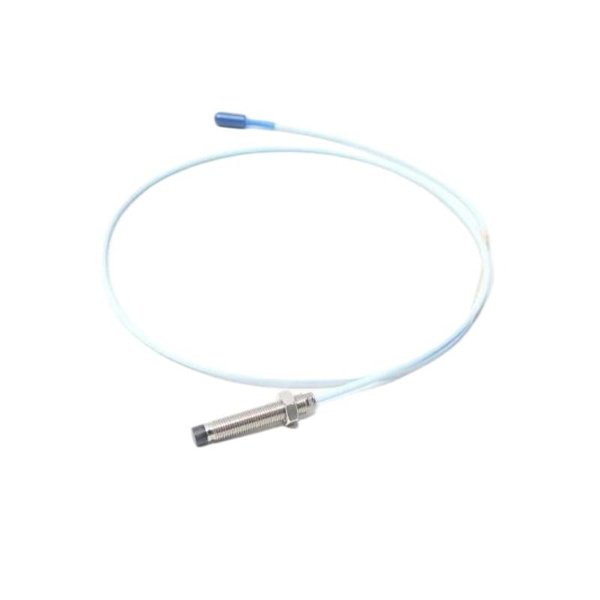

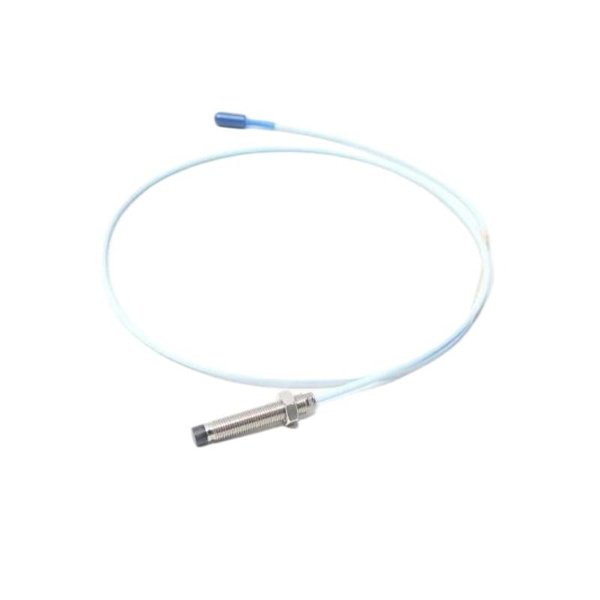

Bently Nevada 330171-12-23-10-01-05 3300 5mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330171-12-23-10-01-05

Product Type:3300 5mm Proximity Probe

Origin:USA

Total Length:1.0 meter

Weight:0.323 kg

Views:11

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330171-12-23-10-01-05 is a high-precision 5mm proximity probe designed for non-contact vibration and displacement measurement in rotating machinery. As part of the 3300 XL series, this probe is engineered to provide accurate and reliable data for condition monitoring and predictive maintenance applications. Its robust construction and advanced features make it suitable for use in various industrial environments, including power generation, oil and gas, and manufacturing sectors.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 330171-12-23-10-01-05 |

| Probe Type | 5mm Proximity Probe |

| Total Length | 1.0 meter (3.3 feet) |

| Weight | 0.323 kg |

| Unthreaded Length | 1.2 inches (30.5 mm) |

| Overall Case Length | 2.3 inches (58.4 mm) |

| Connector Type | Miniature coaxial ClickLoc connector |

| Agency Approvals | Multiple approvals |

| Sensing Range | ±5mm |

| Output Signal | 4-20 mA, proportional to vibration levels |

| Operating Temperature | -40°C to +120°C |

| Material | Stainless Steel / High-Grade Alloy |

| Mounting | Standard or custom mountable |

| Pressure Rating | 1 MPa (Max) |

Applications

The 3300 5mm proximity probe is widely used in various industrial applications:

Vibration Monitoring: Essential for detecting vibration and displacement anomalies in rotating equipment.

Condition Monitoring: Plays a crucial role in predictive maintenance programs by providing early warnings of mechanical faults.

Turbine and Compressor Protection: Monitors shaft displacement to protect turbines and compressors from potential damage.

Pump and Motor Health: Ensures the health of pumps and motors by continuously monitoring their operational conditions.

Wind Turbines: Provides real-time monitoring of wind turbine performance and reliability.

Industrial Equipment: Used across industries like power plants, mining, and manufacturing for machinery protection.

Advantages

The Bently Nevada 330171-12-23-10-01-05 proximity probe offers several key benefits:

High Precision: Delivers accurate vibration and displacement measurements for optimal monitoring.

Robust and Durable: Constructed from high-quality stainless steel and alloys, ensuring long service life even in harsh industrial environments.

Wide Operating Range: Capable of operating in temperatures from -40°C to +120°C, making it suitable for various environments.

Advanced Fault Detection: Identifies potential faults early, helping reduce downtime and prevent equipment failure.

Flexible Mounting: Can be customized to fit various machinery types, offering flexibility in deployment.

Proven Performance: Trusted in industries worldwide for its reliable performance in mission-critical applications.

Predictive Maintenance: Plays a vital role in predictive maintenance strategies by providing real-time data on machine conditions.

Seamless Integration: Easily integrates with existing Bently Nevada monitoring systems, including 3500 and 3300 series.

Cost-Efficient: Helps prevent costly downtime and repairs by offering early warnings and enabling targeted maintenance.

Compact Design: Designed to fit into tight spaces without compromising functionality.

FAQ

Q1: What is the primary function of the Bently Nevada 330171-12-23-10-01-05 proximity probe?

A1: The primary function of this probe is to measure displacement and vibration in rotating machinery for condition monitoring and fault detection.

Q2: What industries typically use this proximity probe?

A2: It is widely used in industries such as power generation, oil and gas, chemical processing, manufacturing, and mining.

Q3: Can this probe be used with any machine?

A3: Yes, the probe is versatile and can be mounted on a variety of rotating equipment, including turbines, compressors, motors, and pumps.

Q4: What type of output does the probe provide?

A4: The probe outputs a 4-20 mA signal, proportional to the vibration or displacement measured.

Q5: Is this proximity probe suitable for extreme temperatures?

A5: Yes, it operates effectively in a temperature range from -40°C to +120°C, making it suitable for harsh industrial environments.

Q6: How does the 3300 proximity probe assist in predictive maintenance?

A6: The probe detects subtle changes in machinery vibration and displacement, providing early warning signs of mechanical issues, thus enabling preventive actions before failure occurs.

Q7: Is it easy to install the probe on existing equipment?

A7: Yes, the probe can be easily integrated with existing machinery, and its mounting options can be customized for specific installation requirements.

Q8: Does the probe require regular calibration?

A8: While the probe is highly accurate, regular calibration is recommended to maintain optimal performance over time.

Q9: Can the 3300 probe be used in offshore applications?

A9: Yes, the probe is designed for high durability and can be used in offshore and other challenging environments, such as those found in oil rigs.

Q10: How does this probe compare to other proximity probes in terms of reliability?

A10: The Bently Nevada 330171-12-23-10-01-05 is known for its high reliability, providing accurate, real-time data that ensures optimal machinery health monitoring.

Bently Nevada 330171-12-23-10-01-05 3300 5mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330171-12-23-10-01-05

Product Type:3300 5mm Proximity Probe

Origin:USA

Total Length:1.0 meter

Weight:0.323 kg

Views:11

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330171-12-23-10-01-05 is a high-precision 5mm proximity probe designed for non-contact vibration and displacement measurement in rotating machinery. As part of the 3300 XL series, this probe is engineered to provide accurate and reliable data for condition monitoring and predictive maintenance applications. Its robust construction and advanced features make it suitable for use in various industrial environments, including power generation, oil and gas, and manufacturing sectors.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 330171-12-23-10-01-05 |

| Probe Type | 5mm Proximity Probe |

| Total Length | 1.0 meter (3.3 feet) |

| Weight | 0.323 kg |

| Unthreaded Length | 1.2 inches (30.5 mm) |

| Overall Case Length | 2.3 inches (58.4 mm) |

| Connector Type | Miniature coaxial ClickLoc connector |

| Agency Approvals | Multiple approvals |

| Sensing Range | ±5mm |

| Output Signal | 4-20 mA, proportional to vibration levels |

| Operating Temperature | -40°C to +120°C |

| Material | Stainless Steel / High-Grade Alloy |

| Mounting | Standard or custom mountable |

| Pressure Rating | 1 MPa (Max) |

Applications

The 3300 5mm proximity probe is widely used in various industrial applications:

Vibration Monitoring: Essential for detecting vibration and displacement anomalies in rotating equipment.

Condition Monitoring: Plays a crucial role in predictive maintenance programs by providing early warnings of mechanical faults.

Turbine and Compressor Protection: Monitors shaft displacement to protect turbines and compressors from potential damage.

Pump and Motor Health: Ensures the health of pumps and motors by continuously monitoring their operational conditions.

Wind Turbines: Provides real-time monitoring of wind turbine performance and reliability.

Industrial Equipment: Used across industries like power plants, mining, and manufacturing for machinery protection.

Advantages

The Bently Nevada 330171-12-23-10-01-05 proximity probe offers several key benefits:

High Precision: Delivers accurate vibration and displacement measurements for optimal monitoring.

Robust and Durable: Constructed from high-quality stainless steel and alloys, ensuring long service life even in harsh industrial environments.

Wide Operating Range: Capable of operating in temperatures from -40°C to +120°C, making it suitable for various environments.

Advanced Fault Detection: Identifies potential faults early, helping reduce downtime and prevent equipment failure.

Flexible Mounting: Can be customized to fit various machinery types, offering flexibility in deployment.

Proven Performance: Trusted in industries worldwide for its reliable performance in mission-critical applications.

Predictive Maintenance: Plays a vital role in predictive maintenance strategies by providing real-time data on machine conditions.

Seamless Integration: Easily integrates with existing Bently Nevada monitoring systems, including 3500 and 3300 series.

Cost-Efficient: Helps prevent costly downtime and repairs by offering early warnings and enabling targeted maintenance.

Compact Design: Designed to fit into tight spaces without compromising functionality.

FAQ

Q1: What is the primary function of the Bently Nevada 330171-12-23-10-01-05 proximity probe?

A1: The primary function of this probe is to measure displacement and vibration in rotating machinery for condition monitoring and fault detection.

Q2: What industries typically use this proximity probe?

A2: It is widely used in industries such as power generation, oil and gas, chemical processing, manufacturing, and mining.

Q3: Can this probe be used with any machine?

A3: Yes, the probe is versatile and can be mounted on a variety of rotating equipment, including turbines, compressors, motors, and pumps.

Q4: What type of output does the probe provide?

A4: The probe outputs a 4-20 mA signal, proportional to the vibration or displacement measured.

Q5: Is this proximity probe suitable for extreme temperatures?

A5: Yes, it operates effectively in a temperature range from -40°C to +120°C, making it suitable for harsh industrial environments.

Q6: How does the 3300 proximity probe assist in predictive maintenance?

A6: The probe detects subtle changes in machinery vibration and displacement, providing early warning signs of mechanical issues, thus enabling preventive actions before failure occurs.

Q7: Is it easy to install the probe on existing equipment?

A7: Yes, the probe can be easily integrated with existing machinery, and its mounting options can be customized for specific installation requirements.

Q8: Does the probe require regular calibration?

A8: While the probe is highly accurate, regular calibration is recommended to maintain optimal performance over time.

Q9: Can the 3300 probe be used in offshore applications?

A9: Yes, the probe is designed for high durability and can be used in offshore and other challenging environments, such as those found in oil rigs.

Q10: How does this probe compare to other proximity probes in terms of reliability?

A10: The Bently Nevada 330171-12-23-10-01-05 is known for its high reliability, providing accurate, real-time data that ensures optimal machinery health monitoring.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...