Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

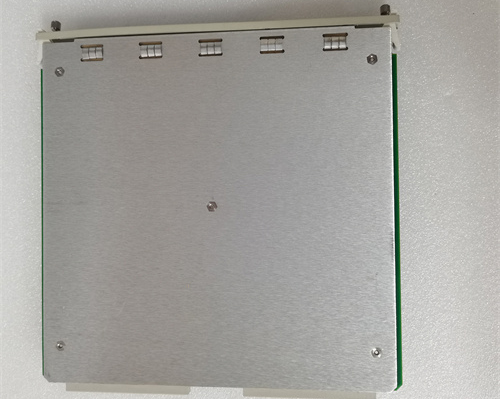

Bently Nevada 2300/20-20 Vibration Monitor

Manufacturer:Bently Nevada

Product Number:2300/20-20

Product Type:Vibration Monitor

Origin:USA

Dimensions:127 x 127 x 76.2 mm

Weight:1.03 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 2300/20-20 Vibration Monitor is a high-performance, dual-channel device engineered for continuous vibration and position monitoring of critical rotating machinery. Designed to provide real-time insights, it enhances the reliability of industrial assets by detecting early signs of mechanical issues such as imbalance, misalignment, and bearing wear. This model integrates advanced monitoring functions with configurable alarms, ensuring effective protection against unexpected failures. It supports API 670 compliance, making it suitable for demanding applications in oil and gas, power generation, and other heavy industries.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Bently Nevada 2300/20-20 Vibration Monitor |

| Channels | Dual-channel for vibration and speed/position |

| Input Signal | Compatible with proximity probes and accelerometers |

| Power Supply | 24 VDC nominal |

| Operating Temperature | -30°C to +65°C |

| Communication Protocol | Modbus RTU and Modbus TCP over Ethernet |

| Alarm Relays | 4 programmable relays |

| Compliance | API 670, CE, UL |

| Dimensions (H x W x D) | 127 x 127 x 76.2 mm |

| Weight | 1.03 kg |

Applications

The 2300/20-20 is widely used for:

Pumps: Detect cavitation and imbalance for efficient operation.

Compressors: Continuous monitoring to avoid catastrophic failures.

Fans and Blowers: Identify vibration-related issues early to prevent breakdowns.

Gearboxes: Ensure proper alignment and lubrication to extend lifespan.

Turbines: Monitor shaft vibration and position to maintain performance integrity.

Advantages

Early Fault Detection: Identifies mechanical issues before they cause downtime.

Dual-Channel Monitoring: Simultaneously tracks vibration and position or speed.

API 670 Compliance: Meets industry standards for machine protection.

Flexible Integration: Supports Modbus and Ethernet communication for easy connectivity.

User-Friendly Interface: Intuitive configuration for quick setup and adjustments.

High Reliability: Engineered for harsh industrial environments.

FAQ

What types of sensors are compatible with the 2300/20-20 monitor?

It supports proximity probes, accelerometers, and velocity transducers compliant with Bently Nevada standards.

Can the device monitor both vibration and position simultaneously?

Yes, it is a dual-channel monitor that can handle vibration and either position or speed measurement at the same time.

Does this model provide configurable alarm limits?

Yes, the 2300/20-20 includes user-configurable alarm thresholds for vibration and speed/position signals.

Is the 2300/20-20 capable of communicating with a DCS or PLC?

Yes, it supports Modbus RTU and Modbus TCP protocols for integration with control systems.

What is the power supply requirement for this monitor?

The unit operates on a 24 VDC nominal power supply.

How many relay outputs are available on the device?

The monitor is equipped with four programmable relay outputs.

Can this monitor be installed in hazardous areas?

Yes, it complies with certifications for hazardous environments depending on selected options.

Does it store historical vibration data?

The 2300 series supports basic data trending and can be integrated with System 1 software for advanced data analysis.

What is the recommended operating temperature range?

The monitor is designed to operate in environments ranging from -30°C to +65°C.

Is firmware upgrade possible without removing the unit from service?

Yes, firmware can be upgraded remotely through its communication interface.

Bently Nevada 2300/20-20 Vibration Monitor

Manufacturer:Bently Nevada

Product Number:2300/20-20

Product Type:Vibration Monitor

Origin:USA

Dimensions:127 x 127 x 76.2 mm

Weight:1.03 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 2300/20-20 Vibration Monitor is a high-performance, dual-channel device engineered for continuous vibration and position monitoring of critical rotating machinery. Designed to provide real-time insights, it enhances the reliability of industrial assets by detecting early signs of mechanical issues such as imbalance, misalignment, and bearing wear. This model integrates advanced monitoring functions with configurable alarms, ensuring effective protection against unexpected failures. It supports API 670 compliance, making it suitable for demanding applications in oil and gas, power generation, and other heavy industries.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Bently Nevada 2300/20-20 Vibration Monitor |

| Channels | Dual-channel for vibration and speed/position |

| Input Signal | Compatible with proximity probes and accelerometers |

| Power Supply | 24 VDC nominal |

| Operating Temperature | -30°C to +65°C |

| Communication Protocol | Modbus RTU and Modbus TCP over Ethernet |

| Alarm Relays | 4 programmable relays |

| Compliance | API 670, CE, UL |

| Dimensions (H x W x D) | 127 x 127 x 76.2 mm |

| Weight | 1.03 kg |

Applications

The 2300/20-20 is widely used for:

Pumps: Detect cavitation and imbalance for efficient operation.

Compressors: Continuous monitoring to avoid catastrophic failures.

Fans and Blowers: Identify vibration-related issues early to prevent breakdowns.

Gearboxes: Ensure proper alignment and lubrication to extend lifespan.

Turbines: Monitor shaft vibration and position to maintain performance integrity.

Advantages

Early Fault Detection: Identifies mechanical issues before they cause downtime.

Dual-Channel Monitoring: Simultaneously tracks vibration and position or speed.

API 670 Compliance: Meets industry standards for machine protection.

Flexible Integration: Supports Modbus and Ethernet communication for easy connectivity.

User-Friendly Interface: Intuitive configuration for quick setup and adjustments.

High Reliability: Engineered for harsh industrial environments.

FAQ

What types of sensors are compatible with the 2300/20-20 monitor?

It supports proximity probes, accelerometers, and velocity transducers compliant with Bently Nevada standards.

Can the device monitor both vibration and position simultaneously?

Yes, it is a dual-channel monitor that can handle vibration and either position or speed measurement at the same time.

Does this model provide configurable alarm limits?

Yes, the 2300/20-20 includes user-configurable alarm thresholds for vibration and speed/position signals.

Is the 2300/20-20 capable of communicating with a DCS or PLC?

Yes, it supports Modbus RTU and Modbus TCP protocols for integration with control systems.

What is the power supply requirement for this monitor?

The unit operates on a 24 VDC nominal power supply.

How many relay outputs are available on the device?

The monitor is equipped with four programmable relay outputs.

Can this monitor be installed in hazardous areas?

Yes, it complies with certifications for hazardous environments depending on selected options.

Does it store historical vibration data?

The 2300 series supports basic data trending and can be integrated with System 1 software for advanced data analysis.

What is the recommended operating temperature range?

The monitor is designed to operate in environments ranging from -30°C to +65°C.

Is firmware upgrade possible without removing the unit from service?

Yes, firmware can be upgraded remotely through its communication interface.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...