Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

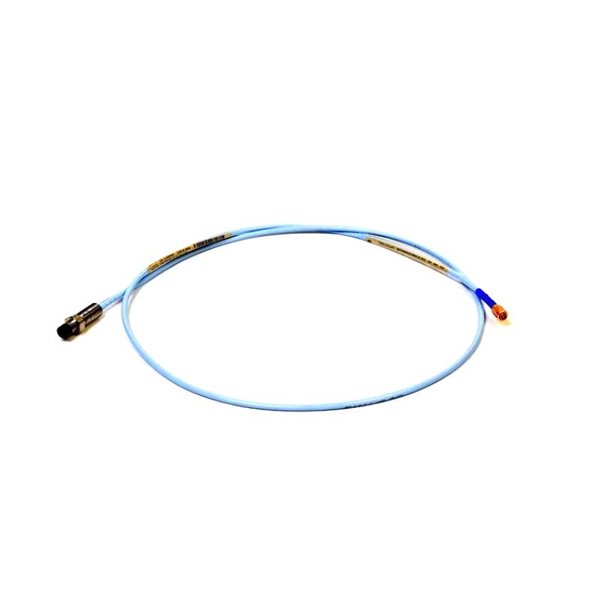

Bently Nevada 330103-00-07-50-02-00 3300 XL 8mm Eddy Current Probe

Manufacturer:Bently Nevada

Product Number:330103-00-07-50-02-00

Product Type:3300 XL 8mm Eddy Current Probe

Origin:USA

Total Length:5.0 meter

Weight:1.615kg

Views:26

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-07-50-02-00 3300 XL 8mm Eddy Current Probe is designed for high-precision measurement and real-time monitoring of the displacement and vibration of rotating machinery. A part of the renowned 3300 XL series, this eddy current probe is engineered to provide reliable and accurate data, offering a vital tool for predictive maintenance and machinery protection.

With an 8mm diameter, the probe is versatile enough to be used in a wide variety of equipment and installations. The 5.0-meter cable offers ample length for flexible installation in both compact and large machines. By using the eddy current principle, the probe effectively measures changes in relative position between the probe and the target without physical contact, making it ideal for environments where traditional methods might not be effective due to space, temperature, or electrical interference.

The 3300 XL Eddy Current Probe is commonly used in industries such as power generation, oil & gas, chemical processing, and manufacturing. It provides the capability to monitor turbines, compressors, pumps, motors, and other critical machinery, ensuring that issues such as misalignment, imbalance, and bearing wear are detected before they result in unplanned downtime or failure.

Product Specifications

| Specification | Details |

|---|---|

| Total Length | 5.0 meters |

| Weight | 1.615 kg |

| Probe Diameter | 8 mm |

| Measurement Type | Eddy Current |

| Cable Length | 5.0 meters |

| Operating Temperature | -40°C to +85°C |

| Signal Output | Analog (4-20 mA or 0-10V) |

| Mounting Type | Direct Surface Mounting |

| Protection Rating | IP65 |

| Compliance | CE, UL Certified |

Applications

The Bently Nevada 330103-00-07-50-02-00 3300 XL 8mm Eddy Current Probe is used in various industries where reliable vibration and displacement monitoring is critical for the health and safety of machinery:

Power Generation: The probe is commonly used in power plants to monitor turbines, compressors, and other rotating machinery, ensuring early detection of imbalances or mechanical issues.

Oil & Gas: In oil rigs and refineries, it ensures the safe operation of pumps, motors, and compressors, preventing costly downtime and ensuring efficient operations.

Chemical Processing: The probe helps monitor the health of equipment in chemical plants, including pumps and turbines, providing data for predictive maintenance and avoiding unexpected failures.

Manufacturing: Used in industrial facilities, it helps monitor motors, conveyors, and other critical equipment, ensuring smooth production and reducing risk.

HVAC Systems: The eddy current probe ensures the smooth operation of components like blowers, fans, and cooling towers in HVAC systems by monitoring their vibration levels.

Marine & Aerospace: In marine engines and aerospace turbines, the probe provides essential monitoring of rotational machinery, helping avoid failures in demanding environments.

Mining and Heavy Industry: In mining operations, it is used to monitor the performance of crushers, mills, and conveyors, providing real-time data for optimal efficiency and safety.

Automated Manufacturing Lines: The probe plays a crucial role in monitoring automated production lines, ensuring machinery is operating at optimal levels and preventing unscheduled downtime.

Product Advantages

Precision and Accuracy: The eddy current principle ensures high precision in vibration and displacement monitoring, allowing for accurate early detection of equipment failure or damage.

Long Cable Length: The 5.0-meter cable provides flexibility in installation, allowing for monitoring across large machines or in spaces that are difficult to reach.

Real-Time Data: The probe offers continuous, real-time data, enabling operators to respond quickly to changing conditions and prevent costly machinery failures.

Durable and Reliable: Designed to withstand harsh industrial conditions, the 3300 XL probe is built to last with minimal maintenance requirements, ensuring reliable operation over extended periods.

Wide Temperature Range: Operating in temperatures from -40°C to +85°C, the probe can function effectively in both hot and cold environments.

Compact Design: The 8mm diameter makes this probe suitable for installation in a variety of rotating machinery with different space constraints.

Easy Integration: The probe integrates easily into existing monitoring systems, providing output signals of 4-20 mA or 0-10V for compatibility with a variety of control systems.

Industry-Leading Technology: The 3300 XL series is recognized as a leader in vibration and displacement monitoring, with more than 30 years of proven performance in demanding environments.

Cost Savings: By enabling early detection of machine wear or imbalance, the probe helps reduce the need for emergency repairs and costly downtime, offering long-term savings.

Enhanced Protection: The IP65 protection rating ensures that the probe is protected from dust and moisture, making it suitable for use in harsh industrial environments.

FAQs

What is the total length of the Bently Nevada 3300 XL Eddy Current Probe?

The total length is 5.0 meters.

How much does the probe weigh?

The probe weighs 1.615 kg.

What is the diameter of the Bently Nevada 3300 XL probe?

The diameter is 8 mm.

What is the operating temperature range of the probe?

The operating temperature range is from -40°C to +85°C.

What type of output does the probe provide?

The probe provides an analog signal output, typically 4-20 mA or 0-10V.

What is the protection rating of the Bently Nevada 3300 XL Eddy Current Probe?

The probe has an IP65 protection rating, meaning it is resistant to dust and moisture.

What industries can use the Bently Nevada 3300 XL Eddy Current Probe?

It is used in power generation, oil & gas, chemical processing, manufacturing, HVAC systems, and more.

Can the Bently Nevada 3300 XL probe be used for monitoring turbines?

Yes, the probe is commonly used in turbine monitoring for detecting vibration and displacement issues.

How does the Bently Nevada 3300 XL probe help prevent unplanned downtime?

By providing real-time data on the health of machinery, it allows for early detection of potential issues, enabling predictive maintenance.

Is the Bently Nevada 3300 XL Eddy Current Probe easy to install?

Yes, the probe is designed for easy installation and can be mounted directly on machinery with simple integration into existing monitoring systems.

Bently Nevada 330103-00-07-50-02-00 3300 XL 8mm Eddy Current Probe

Manufacturer:Bently Nevada

Product Number:330103-00-07-50-02-00

Product Type:3300 XL 8mm Eddy Current Probe

Origin:USA

Total Length:5.0 meter

Weight:1.615kg

Views:26

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-07-50-02-00 3300 XL 8mm Eddy Current Probe is designed for high-precision measurement and real-time monitoring of the displacement and vibration of rotating machinery. A part of the renowned 3300 XL series, this eddy current probe is engineered to provide reliable and accurate data, offering a vital tool for predictive maintenance and machinery protection.

With an 8mm diameter, the probe is versatile enough to be used in a wide variety of equipment and installations. The 5.0-meter cable offers ample length for flexible installation in both compact and large machines. By using the eddy current principle, the probe effectively measures changes in relative position between the probe and the target without physical contact, making it ideal for environments where traditional methods might not be effective due to space, temperature, or electrical interference.

The 3300 XL Eddy Current Probe is commonly used in industries such as power generation, oil & gas, chemical processing, and manufacturing. It provides the capability to monitor turbines, compressors, pumps, motors, and other critical machinery, ensuring that issues such as misalignment, imbalance, and bearing wear are detected before they result in unplanned downtime or failure.

Product Specifications

| Specification | Details |

|---|---|

| Total Length | 5.0 meters |

| Weight | 1.615 kg |

| Probe Diameter | 8 mm |

| Measurement Type | Eddy Current |

| Cable Length | 5.0 meters |

| Operating Temperature | -40°C to +85°C |

| Signal Output | Analog (4-20 mA or 0-10V) |

| Mounting Type | Direct Surface Mounting |

| Protection Rating | IP65 |

| Compliance | CE, UL Certified |

Applications

The Bently Nevada 330103-00-07-50-02-00 3300 XL 8mm Eddy Current Probe is used in various industries where reliable vibration and displacement monitoring is critical for the health and safety of machinery:

Power Generation: The probe is commonly used in power plants to monitor turbines, compressors, and other rotating machinery, ensuring early detection of imbalances or mechanical issues.

Oil & Gas: In oil rigs and refineries, it ensures the safe operation of pumps, motors, and compressors, preventing costly downtime and ensuring efficient operations.

Chemical Processing: The probe helps monitor the health of equipment in chemical plants, including pumps and turbines, providing data for predictive maintenance and avoiding unexpected failures.

Manufacturing: Used in industrial facilities, it helps monitor motors, conveyors, and other critical equipment, ensuring smooth production and reducing risk.

HVAC Systems: The eddy current probe ensures the smooth operation of components like blowers, fans, and cooling towers in HVAC systems by monitoring their vibration levels.

Marine & Aerospace: In marine engines and aerospace turbines, the probe provides essential monitoring of rotational machinery, helping avoid failures in demanding environments.

Mining and Heavy Industry: In mining operations, it is used to monitor the performance of crushers, mills, and conveyors, providing real-time data for optimal efficiency and safety.

Automated Manufacturing Lines: The probe plays a crucial role in monitoring automated production lines, ensuring machinery is operating at optimal levels and preventing unscheduled downtime.

Product Advantages

Precision and Accuracy: The eddy current principle ensures high precision in vibration and displacement monitoring, allowing for accurate early detection of equipment failure or damage.

Long Cable Length: The 5.0-meter cable provides flexibility in installation, allowing for monitoring across large machines or in spaces that are difficult to reach.

Real-Time Data: The probe offers continuous, real-time data, enabling operators to respond quickly to changing conditions and prevent costly machinery failures.

Durable and Reliable: Designed to withstand harsh industrial conditions, the 3300 XL probe is built to last with minimal maintenance requirements, ensuring reliable operation over extended periods.

Wide Temperature Range: Operating in temperatures from -40°C to +85°C, the probe can function effectively in both hot and cold environments.

Compact Design: The 8mm diameter makes this probe suitable for installation in a variety of rotating machinery with different space constraints.

Easy Integration: The probe integrates easily into existing monitoring systems, providing output signals of 4-20 mA or 0-10V for compatibility with a variety of control systems.

Industry-Leading Technology: The 3300 XL series is recognized as a leader in vibration and displacement monitoring, with more than 30 years of proven performance in demanding environments.

Cost Savings: By enabling early detection of machine wear or imbalance, the probe helps reduce the need for emergency repairs and costly downtime, offering long-term savings.

Enhanced Protection: The IP65 protection rating ensures that the probe is protected from dust and moisture, making it suitable for use in harsh industrial environments.

FAQs

What is the total length of the Bently Nevada 3300 XL Eddy Current Probe?

The total length is 5.0 meters.

How much does the probe weigh?

The probe weighs 1.615 kg.

What is the diameter of the Bently Nevada 3300 XL probe?

The diameter is 8 mm.

What is the operating temperature range of the probe?

The operating temperature range is from -40°C to +85°C.

What type of output does the probe provide?

The probe provides an analog signal output, typically 4-20 mA or 0-10V.

What is the protection rating of the Bently Nevada 3300 XL Eddy Current Probe?

The probe has an IP65 protection rating, meaning it is resistant to dust and moisture.

What industries can use the Bently Nevada 3300 XL Eddy Current Probe?

It is used in power generation, oil & gas, chemical processing, manufacturing, HVAC systems, and more.

Can the Bently Nevada 3300 XL probe be used for monitoring turbines?

Yes, the probe is commonly used in turbine monitoring for detecting vibration and displacement issues.

How does the Bently Nevada 3300 XL probe help prevent unplanned downtime?

By providing real-time data on the health of machinery, it allows for early detection of potential issues, enabling predictive maintenance.

Is the Bently Nevada 3300 XL Eddy Current Probe easy to install?

Yes, the probe is designed for easy installation and can be mounted directly on machinery with simple integration into existing monitoring systems.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...