Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

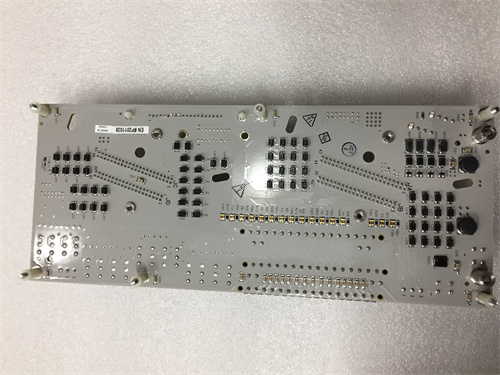

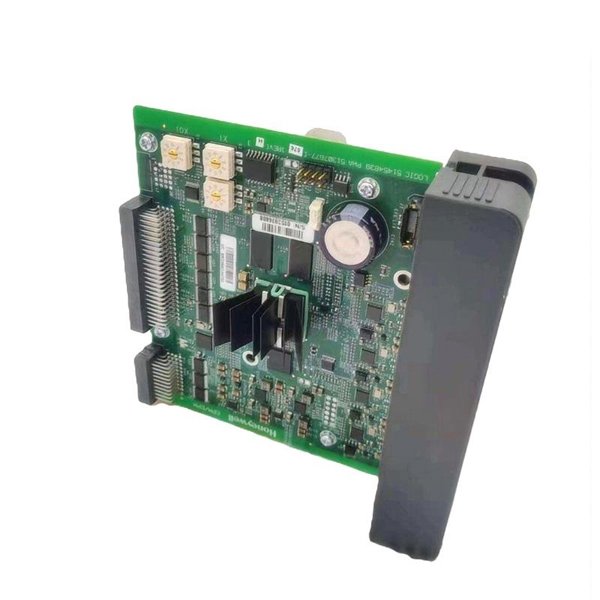

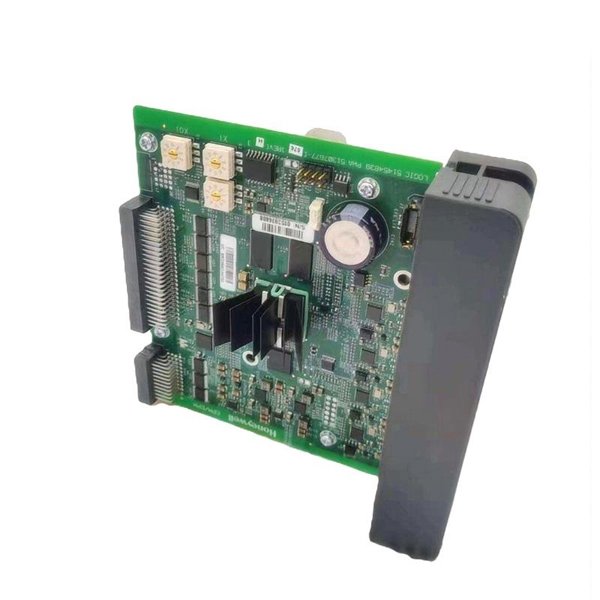

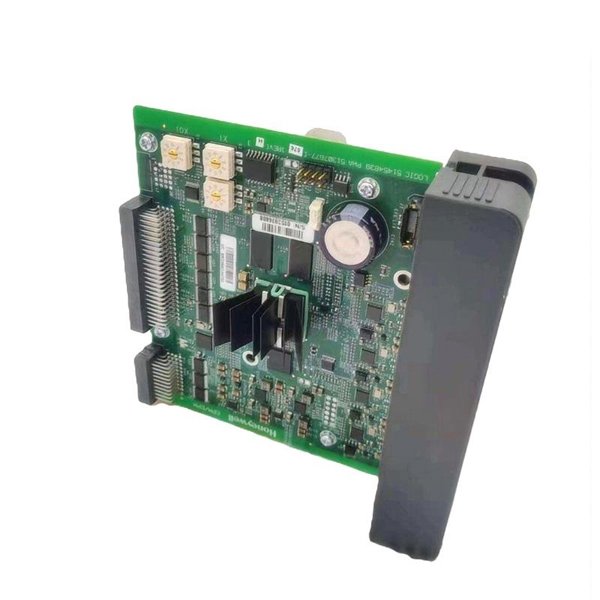

Honeywell 900CP1-0300 Control Processor Module

Manufacturer:Honeywell

Product Number:900CP1-0300

Product Type:Control Processor Module

Origin:USA

Dimensions:137 × 38.1 × 137.2 mm

Weight:0.32 kg

Views:127

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900CP1-0300 Control Processor Module is a high-performance central processing unit (CPU) designed for integration within the HC900 hybrid control system. It functions as the primary decision-making unit, executing control logic, managing I/O communications, and coordinating process operations in real-time.

Engineered for industrial process control, the 900CP1-0300 provides robust processing capabilities with deterministic performance, ensuring reliable operation in diverse industrial environments. The module supports complex control strategies, high-speed data acquisition, and seamless integration with distributed I/O modules, making it suitable for applications requiring precision, stability, and scalability.

Product Parameters

| Parameter | Specification |

|---|---|

| Product Model | Honeywell 900CP1-0300 |

| Module Type | Control Processor Module (CPU) |

| Compatible System | HC900 Hybrid Controller |

| Processing Speed | 32-bit industrial microprocessor |

| Memory | 512 KB program memory, 128 KB data memory |

| Communication Interface | Backplane bus to I/O modules, Ethernet port optional |

| Supported I/O Modules | Digital Input, Digital Output, Analog Input, Analog Output, Pulse/Frequency Modules |

| Programming Language | Honeywell Control Language (HCL) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -20°C to +70°C |

| Relative Humidity | 5% – 95% non-condensing |

| Mounting | HC900 rack mount |

| Dimensions | 137 × 38.1 × 137.2 mm |

| Weight | 0.32 kg |

| Certifications | CE, UL, RoHS compliant |

Product Applications

Industrial Process Control – Centralizes control logic for chemical, petrochemical, and manufacturing processes.

Water and Wastewater Treatment – Manages pumps, valves, and chemical dosing processes with precision.

Power Generation – Coordinates auxiliary systems and turbine control in power plants.

Oil & Gas – Monitors and controls distributed field devices for safe operations.

Pharmaceutical Production – Executes precise batch and continuous process control strategies.

Food and Beverage Manufacturing – Integrates multiple sensors and actuators for automated processing lines.

Product Advantages

High-Performance Processing – 32-bit CPU ensures fast execution of complex control algorithms.

Modular Integration – Interfaces seamlessly with a wide range of HC900 I/O modules.

Real-Time Control – Deterministic operation supports time-critical industrial processes.

Flexible Communication – Backplane and optional Ethernet support for system connectivity.

Scalable System Architecture – Multiple CPUs can be used for distributed or redundant control systems.

Robust Design – Industrial-grade components provide reliability under harsh environmental conditions.

Programmable Control Logic – Supports Honeywell Control Language for customized automation strategies.

Reduced Downtime – Hot-swappable design allows module replacement with minimal disruption.

Comprehensive Diagnostics – Integrated status LEDs and diagnostic ports aid in troubleshooting.

Future-Proof – Compatible with evolving I/O modules and system expansions.

FAQ

Which systems are compatible with the 900CP1-0300?

It is compatible with Honeywell HC900 hybrid control systems.

What type of CPU does the module use?

A 32-bit industrial-grade microprocessor.

How much program memory does it have?

512 KB of program memory and 128 KB of data memory.

Can it communicate with multiple I/O modules simultaneously?

Yes, via the backplane bus and optional Ethernet interface.

Does it support programming languages other than HCL?

No, Honeywell Control Language (HCL) is the standard supported language.

Can multiple 900CP1-0300 modules operate in the same system?

Yes, they can be configured for distributed or redundant control architectures.

Is the module suitable for high-speed process control?

Yes, it provides deterministic real-time processing for fast control loops.

Does it provide system diagnostics?

Yes, integrated LEDs and diagnostic ports indicate module and communication status.

Can the CPU module be replaced without shutting down the system?

Yes, hot-swappable design minimizes downtime in compatible rack configurations.

Which types of I/O modules are supported?

Digital input/output, analog input/output, and pulse/frequency/quadrature modules are fully supported.

Honeywell 900CP1-0300 Control Processor Module

Manufacturer:Honeywell

Product Number:900CP1-0300

Product Type:Control Processor Module

Origin:USA

Dimensions:137 × 38.1 × 137.2 mm

Weight:0.32 kg

Views:127

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Honeywell 900CP1-0300 Control Processor Module is a high-performance central processing unit (CPU) designed for integration within the HC900 hybrid control system. It functions as the primary decision-making unit, executing control logic, managing I/O communications, and coordinating process operations in real-time.

Engineered for industrial process control, the 900CP1-0300 provides robust processing capabilities with deterministic performance, ensuring reliable operation in diverse industrial environments. The module supports complex control strategies, high-speed data acquisition, and seamless integration with distributed I/O modules, making it suitable for applications requiring precision, stability, and scalability.

Product Parameters

| Parameter | Specification |

|---|---|

| Product Model | Honeywell 900CP1-0300 |

| Module Type | Control Processor Module (CPU) |

| Compatible System | HC900 Hybrid Controller |

| Processing Speed | 32-bit industrial microprocessor |

| Memory | 512 KB program memory, 128 KB data memory |

| Communication Interface | Backplane bus to I/O modules, Ethernet port optional |

| Supported I/O Modules | Digital Input, Digital Output, Analog Input, Analog Output, Pulse/Frequency Modules |

| Programming Language | Honeywell Control Language (HCL) |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -20°C to +70°C |

| Relative Humidity | 5% – 95% non-condensing |

| Mounting | HC900 rack mount |

| Dimensions | 137 × 38.1 × 137.2 mm |

| Weight | 0.32 kg |

| Certifications | CE, UL, RoHS compliant |

Product Applications

Industrial Process Control – Centralizes control logic for chemical, petrochemical, and manufacturing processes.

Water and Wastewater Treatment – Manages pumps, valves, and chemical dosing processes with precision.

Power Generation – Coordinates auxiliary systems and turbine control in power plants.

Oil & Gas – Monitors and controls distributed field devices for safe operations.

Pharmaceutical Production – Executes precise batch and continuous process control strategies.

Food and Beverage Manufacturing – Integrates multiple sensors and actuators for automated processing lines.

Product Advantages

High-Performance Processing – 32-bit CPU ensures fast execution of complex control algorithms.

Modular Integration – Interfaces seamlessly with a wide range of HC900 I/O modules.

Real-Time Control – Deterministic operation supports time-critical industrial processes.

Flexible Communication – Backplane and optional Ethernet support for system connectivity.

Scalable System Architecture – Multiple CPUs can be used for distributed or redundant control systems.

Robust Design – Industrial-grade components provide reliability under harsh environmental conditions.

Programmable Control Logic – Supports Honeywell Control Language for customized automation strategies.

Reduced Downtime – Hot-swappable design allows module replacement with minimal disruption.

Comprehensive Diagnostics – Integrated status LEDs and diagnostic ports aid in troubleshooting.

Future-Proof – Compatible with evolving I/O modules and system expansions.

FAQ

Which systems are compatible with the 900CP1-0300?

It is compatible with Honeywell HC900 hybrid control systems.

What type of CPU does the module use?

A 32-bit industrial-grade microprocessor.

How much program memory does it have?

512 KB of program memory and 128 KB of data memory.

Can it communicate with multiple I/O modules simultaneously?

Yes, via the backplane bus and optional Ethernet interface.

Does it support programming languages other than HCL?

No, Honeywell Control Language (HCL) is the standard supported language.

Can multiple 900CP1-0300 modules operate in the same system?

Yes, they can be configured for distributed or redundant control architectures.

Is the module suitable for high-speed process control?

Yes, it provides deterministic real-time processing for fast control loops.

Does it provide system diagnostics?

Yes, integrated LEDs and diagnostic ports indicate module and communication status.

Can the CPU module be replaced without shutting down the system?

Yes, hot-swappable design minimizes downtime in compatible rack configurations.

Which types of I/O modules are supported?

Digital input/output, analog input/output, and pulse/frequency/quadrature modules are fully supported.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...