Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

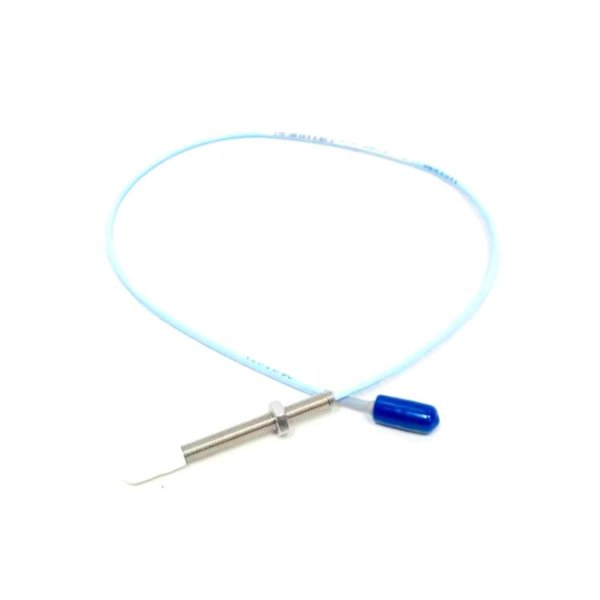

Bently Nevada 330901-00-14-10-02-00 3300 NSv Proximity Probe

Manufacturer:Bently Nevada

Product Number:330901-00-14-10-02-00

Product Type:3300 NSv Proximity Probe

Origin:USA

Total Length:1m

Weight :3 kg

Views:8

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330901-00-14-10-02-00 3300 NSv Proximity Probe is a high-performance proximity transducer designed specifically for measuring vibration, shaft position, and clearance in small and medium-sized machinery. As part of the 3300 NSv (Narrow Side-view) series, this probe is optimized for applications where space is restricted, ensuring accurate signal detection even under challenging installation conditions. It is widely used in turbomachinery monitoring systems, providing precise, reliable data essential for predictive maintenance and asset protection.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330901-00-14-10-02-00 |

| Series | Bently Nevada 3300 NSv Proximity Probes |

| Weight | 3 kg |

| Total Length | 1 m |

| Connector Type | Standard Bently Nevada coaxial connector |

| Material | Stainless steel housing, PEEK insulating tip |

| Frequency Response | DC to 10 kHz typical |

| Operating Temperature | –35 °C to +177 °C |

| Compliance | API 670 compliant |

Product Applications

-

Monitoring shaft vibration and radial displacement in small turbines, compressors, and pumps.

-

Measuring shaft axial position in compact rotating machinery.

-

Providing input signals for condition monitoring systems in petrochemical, power generation, and refining industries.

-

Applications where machine housings have limited space for probe mounting.

-

Integration with 3300 series proximitor sensors for complete vibration monitoring solutions.

Product Advantages

Compact design for installation in space-constrained machinery housings.

High accuracy and reliability for critical turbomachinery protection.

Excellent temperature tolerance allowing use in harsh industrial environments.

API 670 compliance, ensuring it meets global industry standards.

Robust stainless steel and PEEK construction for long-term durability.

Seamless integration with Bently Nevada proximitor systems for comprehensive monitoring.

FAQ

Q1: Can this probe be directly connected to monitoring systems without a proximitor?

A1: No, the probe must be connected to a 3300 NSv Proximitor sensor to condition the signal before transmitting to monitoring systems.

Q2: What is the typical linear measurement range of this probe?

A2: The 3300 NSv probe provides a linear range of approximately 1.0 mm (40 mils) depending on shaft material.

Q3: How does shaft material affect probe calibration?

A3: The probe is factory calibrated for AISI 4140 steel. Other shaft materials require material correction factors for accurate readings.

Q4: Can the probe operate in high-vibration environments?

A4: Yes, it is specifically designed to withstand mechanical vibration and provide stable readings.

Q5: Is the probe sensitive to electromagnetic interference?

A5: The coaxial cable and sensor design provide strong EMI shielding, minimizing interference.

Q6: How does temperature affect measurement accuracy?

A6: Within the specified operating range, the probe compensates for thermal variations and maintains accuracy.

Q7: Can the probe be used in hazardous areas?

A7: Yes, when used with approved proximitor and installation practices, it can meet hazardous area certifications.

Q8: What is the frequency response limit of this probe?

A8: It supports a frequency response from DC up to approximately 10 kHz.

Q9: How should the probe gap be adjusted during installation?

A9: The initial gap should be set within the proximitor’s linear range, typically 1.0 mm, using feeler gauges or calibration tools.

Q10: Can the probe be extended with additional cable length?

A10: Cable length must match the proximitor’s design length; custom factory-matched probe and cable assemblies are required.

Bently Nevada 330901-00-14-10-02-00 3300 NSv Proximity Probe

Manufacturer:Bently Nevada

Product Number:330901-00-14-10-02-00

Product Type:3300 NSv Proximity Probe

Origin:USA

Total Length:1m

Weight :3 kg

Views:8

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330901-00-14-10-02-00 3300 NSv Proximity Probe is a high-performance proximity transducer designed specifically for measuring vibration, shaft position, and clearance in small and medium-sized machinery. As part of the 3300 NSv (Narrow Side-view) series, this probe is optimized for applications where space is restricted, ensuring accurate signal detection even under challenging installation conditions. It is widely used in turbomachinery monitoring systems, providing precise, reliable data essential for predictive maintenance and asset protection.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 330901-00-14-10-02-00 |

| Series | Bently Nevada 3300 NSv Proximity Probes |

| Weight | 3 kg |

| Total Length | 1 m |

| Connector Type | Standard Bently Nevada coaxial connector |

| Material | Stainless steel housing, PEEK insulating tip |

| Frequency Response | DC to 10 kHz typical |

| Operating Temperature | –35 °C to +177 °C |

| Compliance | API 670 compliant |

Product Applications

-

Monitoring shaft vibration and radial displacement in small turbines, compressors, and pumps.

-

Measuring shaft axial position in compact rotating machinery.

-

Providing input signals for condition monitoring systems in petrochemical, power generation, and refining industries.

-

Applications where machine housings have limited space for probe mounting.

-

Integration with 3300 series proximitor sensors for complete vibration monitoring solutions.

Product Advantages

Compact design for installation in space-constrained machinery housings.

High accuracy and reliability for critical turbomachinery protection.

Excellent temperature tolerance allowing use in harsh industrial environments.

API 670 compliance, ensuring it meets global industry standards.

Robust stainless steel and PEEK construction for long-term durability.

Seamless integration with Bently Nevada proximitor systems for comprehensive monitoring.

FAQ

Q1: Can this probe be directly connected to monitoring systems without a proximitor?

A1: No, the probe must be connected to a 3300 NSv Proximitor sensor to condition the signal before transmitting to monitoring systems.

Q2: What is the typical linear measurement range of this probe?

A2: The 3300 NSv probe provides a linear range of approximately 1.0 mm (40 mils) depending on shaft material.

Q3: How does shaft material affect probe calibration?

A3: The probe is factory calibrated for AISI 4140 steel. Other shaft materials require material correction factors for accurate readings.

Q4: Can the probe operate in high-vibration environments?

A4: Yes, it is specifically designed to withstand mechanical vibration and provide stable readings.

Q5: Is the probe sensitive to electromagnetic interference?

A5: The coaxial cable and sensor design provide strong EMI shielding, minimizing interference.

Q6: How does temperature affect measurement accuracy?

A6: Within the specified operating range, the probe compensates for thermal variations and maintains accuracy.

Q7: Can the probe be used in hazardous areas?

A7: Yes, when used with approved proximitor and installation practices, it can meet hazardous area certifications.

Q8: What is the frequency response limit of this probe?

A8: It supports a frequency response from DC up to approximately 10 kHz.

Q9: How should the probe gap be adjusted during installation?

A9: The initial gap should be set within the proximitor’s linear range, typically 1.0 mm, using feeler gauges or calibration tools.

Q10: Can the probe be extended with additional cable length?

A10: Cable length must match the proximitor’s design length; custom factory-matched probe and cable assemblies are required.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...