Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

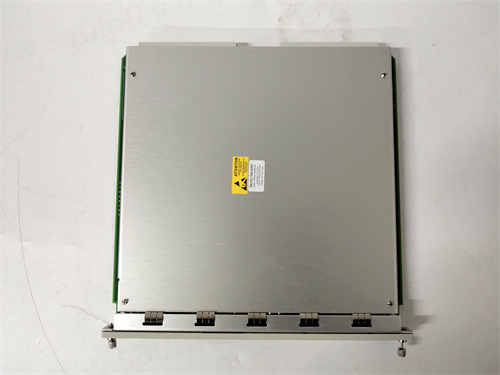

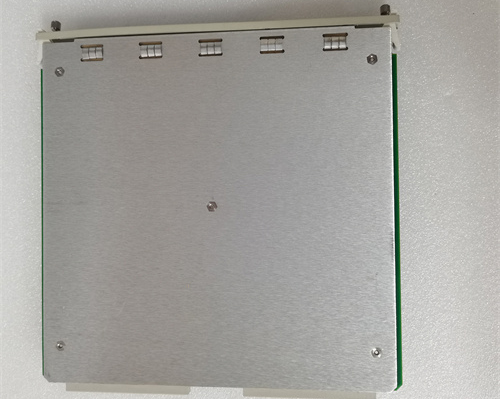

Bently Nevada 991-06-70-01-00 991 Thrust Sensor

Manufacturer:Bently Nevada

Product Number:991-06-70-01-00

Product Type:991 Thrust Sensor

Origin:USA

Dimensions:100.1 x 73.9 x 53.3mm

Weight:0.43kg

Views:51

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 991-06-70-01-00 991 Thrust Transducer is a premium axial position monitoring device designed to deliver accurate and continuous thrust measurement for critical rotating machinery. As part of Bently Nevada’s trusted 991 Series, this sensor plays a vital role in machinery protection by detecting axial shaft movement, commonly referred to as thrust position.

Excessive thrust movement in turbines, compressors, pumps, or other high-value equipment can lead to severe mechanical failures, including bearing or seal damage. The 991-06-70-01-00 model provides precise, real-time measurement, enabling predictive maintenance and safeguarding plant operations. Engineered for harsh industrial environments, it offers reliable performance under extreme temperatures, vibration, and contamination.

Key Features

Real-Time Thrust Position Monitoring: Provides accurate axial shaft position data to prevent equipment damage.

Non-Contact Eddy Current Sensing: Advanced proximity technology ensures reliable, wear-free measurement.

Extended Probe Length: Suitable for deeper installations or where additional reach is required.

High Temperature and Vibration Resistance: Ideal for demanding turbine, compressor, and pump applications.

Compatible with Bently Nevada Systems: Integrates seamlessly with 3300 XL proximity probes, cables, and monitoring systems.

Continuous Machinery Protection: Enables early detection of shaft movement to avoid unplanned shutdowns.

Corrosion-Resistant Stainless Steel Design: Withstands harsh industrial conditions for long-term use.

Compact, Robust Construction: Facilitates installation in tight spaces and high-vibration environments.

Minimal Maintenance Requirement: Designed for durability and operational reliability.

Global Certification Options: Available with CE, ATEX, RoHS compliance for worldwide installations.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | 991-06-70-01-00 |

| Product Type | Thrust (Axial Position) Transducer |

| Measurement Range | Typically 0 to 2 mm (configurable for specific needs) |

| Sensing Technology | Non-contact eddy-current proximity sensing |

| Diameter | 100.1 x 73.9 x 53.3mm |

| Probe Length | 70 mm (extended length for special installations) |

| Output Signal | Compatible with Bently Nevada monitoring systems |

| Body Material | Stainless Steel, corrosion-resistant |

| Operating Temperature Range | -35°C to +177°C (high-temp variants available) |

| Frequency Response | DC to 10 kHz |

| Thread Size | 3/8-24 UNF standard |

| Protection Class | IP65 (dust-tight, resistant to water ingress) |

| Certifications | CE, RoHS, ATEX options available |

| Extension Cable Compatibility | Bently Nevada 3300 XL series extension cables |

| Weight | 0.43 kg |

Industry Applications

Power Generation: Axial position monitoring for steam turbines, generators, and auxiliary rotating machinery.

Oil & Gas Sector: Thrust measurement in compressors, pumps, and turbines used in upstream, midstream, and downstream operations.

Petrochemical and Chemical Plants: Monitoring of thrust movement in critical processing equipment.

Industrial Compressors: Reliable thrust monitoring to extend equipment life and prevent mechanical failures.

Pumps and Rotating Equipment: Early detection of excessive axial shaft movement in pumps and process equipment.

Mining and Metals: Axial displacement monitoring in large rotating machines such as crushers and mills.

Water and Wastewater Facilities: Safeguards pump performance and operational integrity.

Product Advantages

Enhanced Machinery Protection: Detects abnormal axial shaft movement before it results in equipment damage.

Precise, Wear-Free Measurement: Non-contact eddy current technology ensures consistent, maintenance-free operation.

Extended Probe Design: Allows for deeper installations or areas with difficult access.

Robust and Corrosion-Resistant: Stainless steel construction resists harsh environmental conditions.

High-Temperature Capability: Operates reliably in high-heat environments such as steam turbine housings.

Seamless System Integration: Compatible with Bently Nevada’s 3300 XL proximity probes and monitoring systems.

Minimized Downtime Risk: Continuous real-time monitoring facilitates predictive maintenance strategies.

Compact Footprint: Ideal for installations with limited space or challenging mounting locations.

Global Compliance: CE, RoHS, ATEX certified options for use in diverse industrial settings.

Bently Nevada Reliability: Backed by decades of expertise in machinery condition monitoring and protection.

Frequently Asked Questions (FAQ)

What does the 991-06-70-01-00 monitor?

It monitors axial shaft movement (thrust position) in rotating machinery to detect excessive displacement.

What makes the 70 mm version unique?

The extended probe length provides greater reach for deeper or hard-to-access installation points.

Which Bently Nevada systems is it compatible with?

It integrates with Bently Nevada 3300 XL proximity probes, extension cables, and monitoring platforms.

What is the typical measurement range?

Standard measurement range is 0 to 2 mm, configurable based on application requirements.

Is the 991-06-70-01-00 suitable for high temperatures?

Yes, it is designed to operate reliably in temperatures up to +177°C, with high-temperature variants available.

What industries use this thrust transducer?

Power generation, oil & gas, petrochemicals, mining, water treatment, and general manufacturing.

What is the sensor’s output signal?

It provides position feedback to Bently Nevada monitoring systems for real-time analysis and protection.

Is the transducer suitable for hazardous areas?

Yes, ATEX-certified variants are available for use in explosive or hazardous environments.

How is the sensor mounted?

It uses a standard 3/8-24 UNF threaded installation for secure and accurate positioning.

What are the maintenance requirements?

The sensor is designed for minimal maintenance, with durable, wear-free operation under normal conditions.

Bently Nevada 991-06-70-01-00 991 Thrust Sensor

Manufacturer:Bently Nevada

Product Number:991-06-70-01-00

Product Type:991 Thrust Sensor

Origin:USA

Dimensions:100.1 x 73.9 x 53.3mm

Weight:0.43kg

Views:51

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 991-06-70-01-00 991 Thrust Transducer is a premium axial position monitoring device designed to deliver accurate and continuous thrust measurement for critical rotating machinery. As part of Bently Nevada’s trusted 991 Series, this sensor plays a vital role in machinery protection by detecting axial shaft movement, commonly referred to as thrust position.

Excessive thrust movement in turbines, compressors, pumps, or other high-value equipment can lead to severe mechanical failures, including bearing or seal damage. The 991-06-70-01-00 model provides precise, real-time measurement, enabling predictive maintenance and safeguarding plant operations. Engineered for harsh industrial environments, it offers reliable performance under extreme temperatures, vibration, and contamination.

Key Features

Real-Time Thrust Position Monitoring: Provides accurate axial shaft position data to prevent equipment damage.

Non-Contact Eddy Current Sensing: Advanced proximity technology ensures reliable, wear-free measurement.

Extended Probe Length: Suitable for deeper installations or where additional reach is required.

High Temperature and Vibration Resistance: Ideal for demanding turbine, compressor, and pump applications.

Compatible with Bently Nevada Systems: Integrates seamlessly with 3300 XL proximity probes, cables, and monitoring systems.

Continuous Machinery Protection: Enables early detection of shaft movement to avoid unplanned shutdowns.

Corrosion-Resistant Stainless Steel Design: Withstands harsh industrial conditions for long-term use.

Compact, Robust Construction: Facilitates installation in tight spaces and high-vibration environments.

Minimal Maintenance Requirement: Designed for durability and operational reliability.

Global Certification Options: Available with CE, ATEX, RoHS compliance for worldwide installations.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | 991-06-70-01-00 |

| Product Type | Thrust (Axial Position) Transducer |

| Measurement Range | Typically 0 to 2 mm (configurable for specific needs) |

| Sensing Technology | Non-contact eddy-current proximity sensing |

| Diameter | 100.1 x 73.9 x 53.3mm |

| Probe Length | 70 mm (extended length for special installations) |

| Output Signal | Compatible with Bently Nevada monitoring systems |

| Body Material | Stainless Steel, corrosion-resistant |

| Operating Temperature Range | -35°C to +177°C (high-temp variants available) |

| Frequency Response | DC to 10 kHz |

| Thread Size | 3/8-24 UNF standard |

| Protection Class | IP65 (dust-tight, resistant to water ingress) |

| Certifications | CE, RoHS, ATEX options available |

| Extension Cable Compatibility | Bently Nevada 3300 XL series extension cables |

| Weight | 0.43 kg |

Industry Applications

Power Generation: Axial position monitoring for steam turbines, generators, and auxiliary rotating machinery.

Oil & Gas Sector: Thrust measurement in compressors, pumps, and turbines used in upstream, midstream, and downstream operations.

Petrochemical and Chemical Plants: Monitoring of thrust movement in critical processing equipment.

Industrial Compressors: Reliable thrust monitoring to extend equipment life and prevent mechanical failures.

Pumps and Rotating Equipment: Early detection of excessive axial shaft movement in pumps and process equipment.

Mining and Metals: Axial displacement monitoring in large rotating machines such as crushers and mills.

Water and Wastewater Facilities: Safeguards pump performance and operational integrity.

Product Advantages

Enhanced Machinery Protection: Detects abnormal axial shaft movement before it results in equipment damage.

Precise, Wear-Free Measurement: Non-contact eddy current technology ensures consistent, maintenance-free operation.

Extended Probe Design: Allows for deeper installations or areas with difficult access.

Robust and Corrosion-Resistant: Stainless steel construction resists harsh environmental conditions.

High-Temperature Capability: Operates reliably in high-heat environments such as steam turbine housings.

Seamless System Integration: Compatible with Bently Nevada’s 3300 XL proximity probes and monitoring systems.

Minimized Downtime Risk: Continuous real-time monitoring facilitates predictive maintenance strategies.

Compact Footprint: Ideal for installations with limited space or challenging mounting locations.

Global Compliance: CE, RoHS, ATEX certified options for use in diverse industrial settings.

Bently Nevada Reliability: Backed by decades of expertise in machinery condition monitoring and protection.

Frequently Asked Questions (FAQ)

What does the 991-06-70-01-00 monitor?

It monitors axial shaft movement (thrust position) in rotating machinery to detect excessive displacement.

What makes the 70 mm version unique?

The extended probe length provides greater reach for deeper or hard-to-access installation points.

Which Bently Nevada systems is it compatible with?

It integrates with Bently Nevada 3300 XL proximity probes, extension cables, and monitoring platforms.

What is the typical measurement range?

Standard measurement range is 0 to 2 mm, configurable based on application requirements.

Is the 991-06-70-01-00 suitable for high temperatures?

Yes, it is designed to operate reliably in temperatures up to +177°C, with high-temperature variants available.

What industries use this thrust transducer?

Power generation, oil & gas, petrochemicals, mining, water treatment, and general manufacturing.

What is the sensor’s output signal?

It provides position feedback to Bently Nevada monitoring systems for real-time analysis and protection.

Is the transducer suitable for hazardous areas?

Yes, ATEX-certified variants are available for use in explosive or hazardous environments.

How is the sensor mounted?

It uses a standard 3/8-24 UNF threaded installation for secure and accurate positioning.

What are the maintenance requirements?

The sensor is designed for minimal maintenance, with durable, wear-free operation under normal conditions.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...