Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

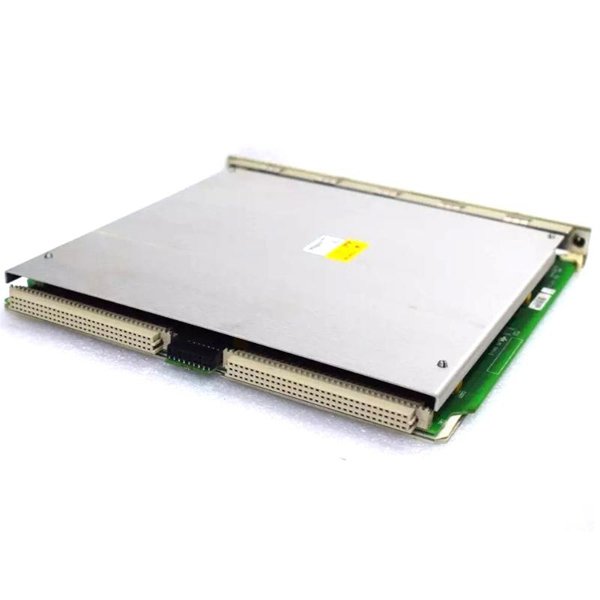

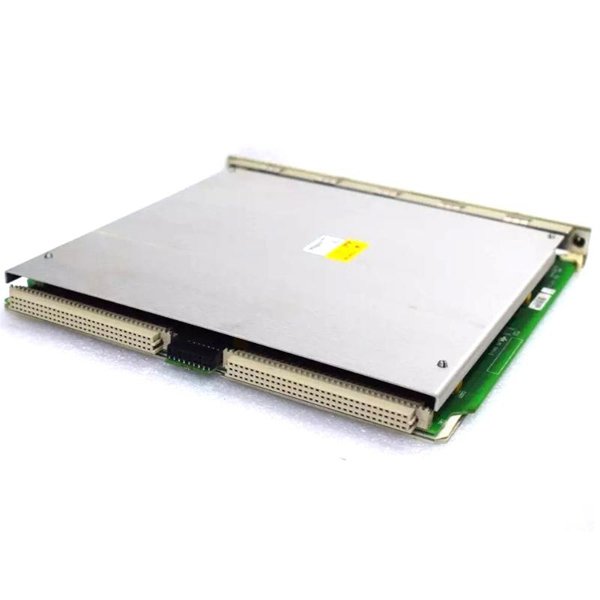

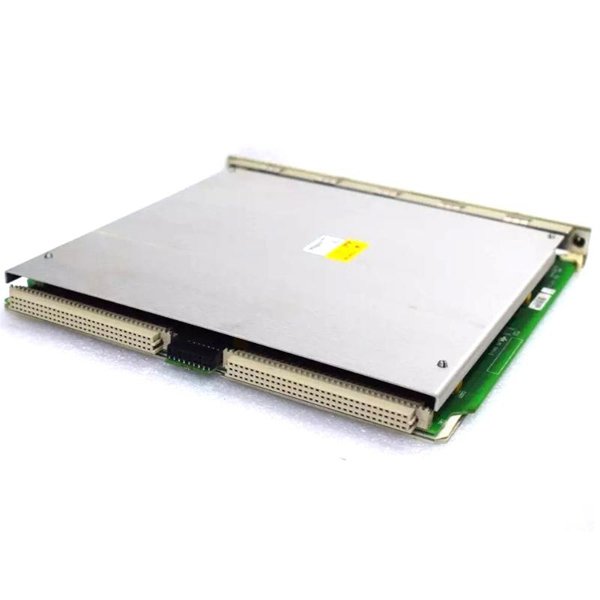

Bently Nevada 3500/42M-01-00 140734-02 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42M-01-00 140734-02

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:54

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42M Proximitor Seismic Monitor is a high-performance, four-channel monitor designed for machinery protection and condition monitoring. It accepts proximity and seismic sensor inputs, conditions the signals to provide accurate vibration and position measurements, and compares them with configurable alarm setpoints. It ensures early detection of machine faults, safeguarding critical rotating equipment.

Technical Specifications

| Parameter | Value |

|---|---|

| Channels | 4 |

| Input Signal Types | Proximity, velocity, acceleration transducers |

| Power Consumption | 7.7 W typical |

| Input Impedance | 10 kΩ |

| Sensitivity | Multiple ranges (e.g., 3.94 mV/µm, 20 mV/mm/s) |

| Frequency Response | Up to 30 kHz depending on mode |

| Alarm Setpoints | Programmable, 0–100% of full-scale |

| Dimensions (H×W×D) | 241.3 × 24.4 × 241.8 mm |

| Weight | 0.91 kg |

| Operating Temperature | -30°C to +65°C |

| Humidity | Up to 95% non-condensing |

| Outputs | 4–20 mA recorder, buffered transducer outputs |

Applications

-

Continuous monitoring of radial and axial vibrations

-

Shaft position and thrust position detection

-

Protection of critical machinery in power plants, refineries, and chemical plants

-

Condition monitoring for predictive maintenance programs

Advantages

-

Versatile input compatibility with proximity and seismic sensors

-

Highly configurable monitoring modes and alarms

-

Compact design with low rack space requirement

-

Reliable performance in harsh industrial environments

-

Supports advanced measurements like REBAM, eccentricity, and differential expansion

FAQ

Q1: What types of sensors are compatible with the 3500/42M?

A1: It supports proximity, velocity, and acceleration transducers.

Q2: How many channels does the module have?

A2: It has four independent monitoring channels.

Q3: Can the alarm thresholds be customized?

A3: Yes, both alert and danger setpoints are fully programmable.

Q4: Does the unit provide buffered transducer outputs?

A4: Yes, each channel has a buffered output available at the front panel.

Q5: What is the typical power consumption?

A5: Approximately 7.7 watts.

Q6: Can it operate in low temperatures?

A6: Yes, it can operate down to -30°C with suitable I/O modules.

Q7: What is the unit’s weight?

A7: The main module weighs 0.91 kg.

Q8: How often does the recorder output update?

A8: Approximately every 100 milliseconds.

Q9: Are internal barriers available for hazardous areas?

A9: Yes, configurations with internal barriers are supported.

Q10: Is the 3500/42M certified for marine applications?

A10: Yes, it meets ABS and DNV GL standards for marine and offshore use.

Bently Nevada 3500/42M-01-00 140734-02 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42M-01-00 140734-02

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:54

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42M Proximitor Seismic Monitor is a high-performance, four-channel monitor designed for machinery protection and condition monitoring. It accepts proximity and seismic sensor inputs, conditions the signals to provide accurate vibration and position measurements, and compares them with configurable alarm setpoints. It ensures early detection of machine faults, safeguarding critical rotating equipment.

Technical Specifications

| Parameter | Value |

|---|---|

| Channels | 4 |

| Input Signal Types | Proximity, velocity, acceleration transducers |

| Power Consumption | 7.7 W typical |

| Input Impedance | 10 kΩ |

| Sensitivity | Multiple ranges (e.g., 3.94 mV/µm, 20 mV/mm/s) |

| Frequency Response | Up to 30 kHz depending on mode |

| Alarm Setpoints | Programmable, 0–100% of full-scale |

| Dimensions (H×W×D) | 241.3 × 24.4 × 241.8 mm |

| Weight | 0.91 kg |

| Operating Temperature | -30°C to +65°C |

| Humidity | Up to 95% non-condensing |

| Outputs | 4–20 mA recorder, buffered transducer outputs |

Applications

-

Continuous monitoring of radial and axial vibrations

-

Shaft position and thrust position detection

-

Protection of critical machinery in power plants, refineries, and chemical plants

-

Condition monitoring for predictive maintenance programs

Advantages

-

Versatile input compatibility with proximity and seismic sensors

-

Highly configurable monitoring modes and alarms

-

Compact design with low rack space requirement

-

Reliable performance in harsh industrial environments

-

Supports advanced measurements like REBAM, eccentricity, and differential expansion

FAQ

Q1: What types of sensors are compatible with the 3500/42M?

A1: It supports proximity, velocity, and acceleration transducers.

Q2: How many channels does the module have?

A2: It has four independent monitoring channels.

Q3: Can the alarm thresholds be customized?

A3: Yes, both alert and danger setpoints are fully programmable.

Q4: Does the unit provide buffered transducer outputs?

A4: Yes, each channel has a buffered output available at the front panel.

Q5: What is the typical power consumption?

A5: Approximately 7.7 watts.

Q6: Can it operate in low temperatures?

A6: Yes, it can operate down to -30°C with suitable I/O modules.

Q7: What is the unit’s weight?

A7: The main module weighs 0.91 kg.

Q8: How often does the recorder output update?

A8: Approximately every 100 milliseconds.

Q9: Are internal barriers available for hazardous areas?

A9: Yes, configurations with internal barriers are supported.

Q10: Is the 3500/42M certified for marine applications?

A10: Yes, it meets ABS and DNV GL standards for marine and offshore use.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...