Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

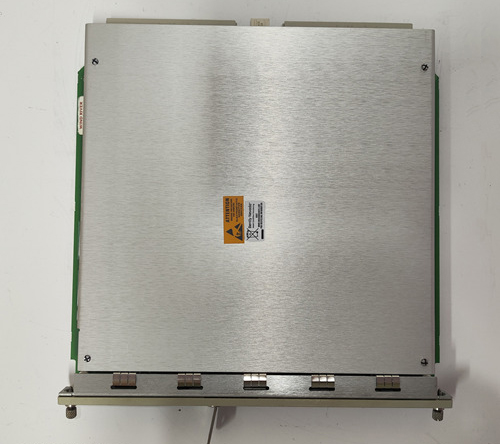

Bently Nevada 177230-02-01-CN Seismic Transmitter

Manufacturer:Bently Nevada

Product Number:177230-02-01-CN

Product Type:Seismic Transmitter

Origin:USA

Sensor Head Diameter:25.4 mm

Weight:0.131 kg

Views:33

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 177230-02-01-CN Seismic Transmitter is a precision-engineered device designed to measure seismic vibration directly from machinery and structures. It converts mechanical vibration signals into a proportional 4–20 mA output, making it suitable for integration with standard control and monitoring systems. With robust construction and advanced internal circuitry, this transmitter ensures high accuracy, reliability, and consistent performance in demanding industrial environments.

This model is part of the Bently Nevada seismic monitoring product line, trusted worldwide for predictive maintenance and machine protection. Its ability to deliver real-time vibration data makes it essential in applications where continuous condition monitoring is critical, such as turbines, compressors, pumps, and other rotating machinery.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 177230-02-01-CN |

| Type | Seismic Transmitter |

| Output Signal | 4–20 mA proportional to vibration |

| Frequency Response | 10 Hz to 1,000 Hz (±3 dB) |

| Measurement Range | Configurable (commonly 0–50 mm/s RMS) |

| Power Supply | 18–36 VDC |

| Operating Temperature | -29 °C to +85 °C (-20 °F to +185 °F) |

| Shock Limit | 500 g, peak |

| Mounting | Base-mounted with threaded holes |

| Housing Material | Corrosion-resistant stainless steel |

| Electrical Connection | Two-wire loop powered |

| Sensor Head Diameter | 25.4 mm |

| Weight | 0.131 kg |

Product Applications

The Bently Nevada 177230-02-01-CN Seismic Transmitter is widely used across industries for machinery protection and vibration monitoring.

Power Generation: Monitoring seismic vibration in turbines, gearboxes, and auxiliary systems.

Oil & Gas: Used in offshore platforms, refineries, and pipelines for critical equipment monitoring.

Petrochemical & Chemical Plants: Provides vibration data to prevent process disruptions.

Heavy Industry: Applied in steel mills, paper manufacturing, and mining operations for predictive maintenance.

Infrastructure Monitoring: Ensures stability and integrity in sensitive facilities, including bridges and large rotating equipment.

Product Advantages

High Reliability: Engineered for continuous operation in harsh industrial environments.

Standardized Output: Provides industry-standard 4–20 mA signals for easy integration into DCS or PLC systems.

Accurate Vibration Measurement: Wide frequency response ensures precise monitoring of machine health.

Compact and Rugged Design: Stainless-steel housing ensures durability and corrosion resistance.

Flexible Applications: Suitable for both machinery protection and predictive maintenance strategies.

Reduced Downtime: Early fault detection prevents catastrophic failures and extends equipment lifespan.

FAQ

What type of signal does the 177230-02-01-CN seismic transmitter provide?

It provides a 4–20 mA output signal proportional to vibration velocity.

Can this transmitter be integrated with a PLC or DCS system?

Yes, it is designed for seamless integration with standard PLC and DCS systems.

What frequency range does this transmitter cover?

It typically covers a range of 10 Hz to 1,000 Hz within ±3 dB accuracy.

Is the transmitter suitable for hazardous area installations?

Yes, certain versions are certified for hazardous areas depending on installation requirements.

How is the transmitter powered?

It operates using a two-wire, loop-powered system with 18–36 VDC supply.

Does it require external signal conditioning?

No, the transmitter provides a conditioned 4–20 mA signal directly, eliminating the need for additional conditioning.

What mounting options are available for this unit?

It is base-mounted using threaded holes, ensuring stable attachment to machinery or structures.

How does the seismic transmitter differ from proximity probes?

While proximity probes measure shaft relative displacement, seismic transmitters measure absolute vibration of the machine case or structure.

What level of shock resistance does this transmitter have?

It can withstand shocks up to 500 g peak without damage.

What industries benefit most from this transmitter?

Industries such as oil & gas, power generation, petrochemical, and heavy industry benefit the most due to its ability to deliver reliable vibration monitoring.

Bently Nevada 177230-02-01-CN Seismic Transmitter

Manufacturer:Bently Nevada

Product Number:177230-02-01-CN

Product Type:Seismic Transmitter

Origin:USA

Sensor Head Diameter:25.4 mm

Weight:0.131 kg

Views:33

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 177230-02-01-CN Seismic Transmitter is a precision-engineered device designed to measure seismic vibration directly from machinery and structures. It converts mechanical vibration signals into a proportional 4–20 mA output, making it suitable for integration with standard control and monitoring systems. With robust construction and advanced internal circuitry, this transmitter ensures high accuracy, reliability, and consistent performance in demanding industrial environments.

This model is part of the Bently Nevada seismic monitoring product line, trusted worldwide for predictive maintenance and machine protection. Its ability to deliver real-time vibration data makes it essential in applications where continuous condition monitoring is critical, such as turbines, compressors, pumps, and other rotating machinery.

Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 177230-02-01-CN |

| Type | Seismic Transmitter |

| Output Signal | 4–20 mA proportional to vibration |

| Frequency Response | 10 Hz to 1,000 Hz (±3 dB) |

| Measurement Range | Configurable (commonly 0–50 mm/s RMS) |

| Power Supply | 18–36 VDC |

| Operating Temperature | -29 °C to +85 °C (-20 °F to +185 °F) |

| Shock Limit | 500 g, peak |

| Mounting | Base-mounted with threaded holes |

| Housing Material | Corrosion-resistant stainless steel |

| Electrical Connection | Two-wire loop powered |

| Sensor Head Diameter | 25.4 mm |

| Weight | 0.131 kg |

Product Applications

The Bently Nevada 177230-02-01-CN Seismic Transmitter is widely used across industries for machinery protection and vibration monitoring.

Power Generation: Monitoring seismic vibration in turbines, gearboxes, and auxiliary systems.

Oil & Gas: Used in offshore platforms, refineries, and pipelines for critical equipment monitoring.

Petrochemical & Chemical Plants: Provides vibration data to prevent process disruptions.

Heavy Industry: Applied in steel mills, paper manufacturing, and mining operations for predictive maintenance.

Infrastructure Monitoring: Ensures stability and integrity in sensitive facilities, including bridges and large rotating equipment.

Product Advantages

High Reliability: Engineered for continuous operation in harsh industrial environments.

Standardized Output: Provides industry-standard 4–20 mA signals for easy integration into DCS or PLC systems.

Accurate Vibration Measurement: Wide frequency response ensures precise monitoring of machine health.

Compact and Rugged Design: Stainless-steel housing ensures durability and corrosion resistance.

Flexible Applications: Suitable for both machinery protection and predictive maintenance strategies.

Reduced Downtime: Early fault detection prevents catastrophic failures and extends equipment lifespan.

FAQ

What type of signal does the 177230-02-01-CN seismic transmitter provide?

It provides a 4–20 mA output signal proportional to vibration velocity.

Can this transmitter be integrated with a PLC or DCS system?

Yes, it is designed for seamless integration with standard PLC and DCS systems.

What frequency range does this transmitter cover?

It typically covers a range of 10 Hz to 1,000 Hz within ±3 dB accuracy.

Is the transmitter suitable for hazardous area installations?

Yes, certain versions are certified for hazardous areas depending on installation requirements.

How is the transmitter powered?

It operates using a two-wire, loop-powered system with 18–36 VDC supply.

Does it require external signal conditioning?

No, the transmitter provides a conditioned 4–20 mA signal directly, eliminating the need for additional conditioning.

What mounting options are available for this unit?

It is base-mounted using threaded holes, ensuring stable attachment to machinery or structures.

How does the seismic transmitter differ from proximity probes?

While proximity probes measure shaft relative displacement, seismic transmitters measure absolute vibration of the machine case or structure.

What level of shock resistance does this transmitter have?

It can withstand shocks up to 500 g peak without damage.

What industries benefit most from this transmitter?

Industries such as oil & gas, power generation, petrochemical, and heavy industry benefit the most due to its ability to deliver reliable vibration monitoring.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...