Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

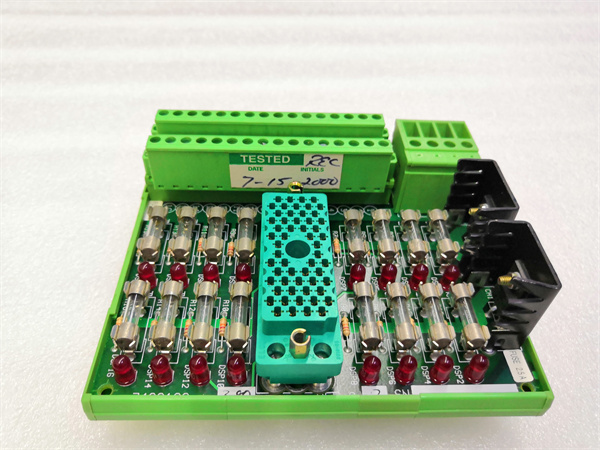

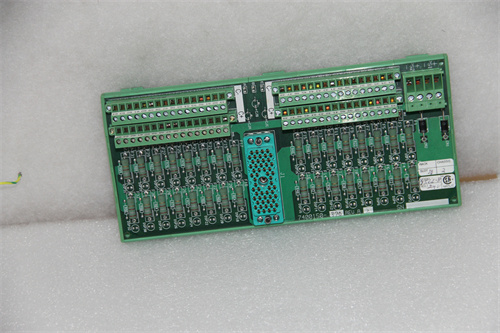

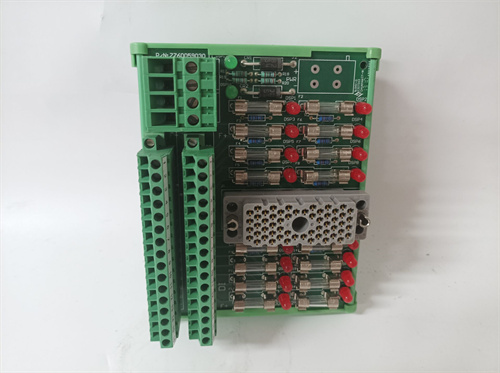

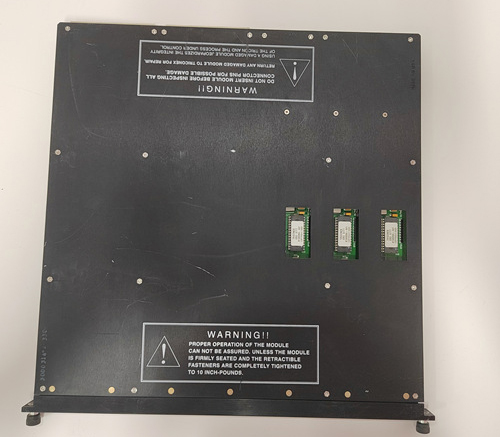

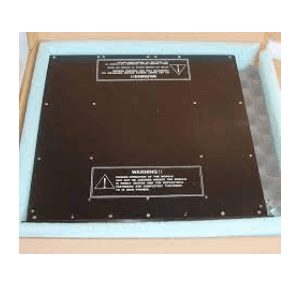

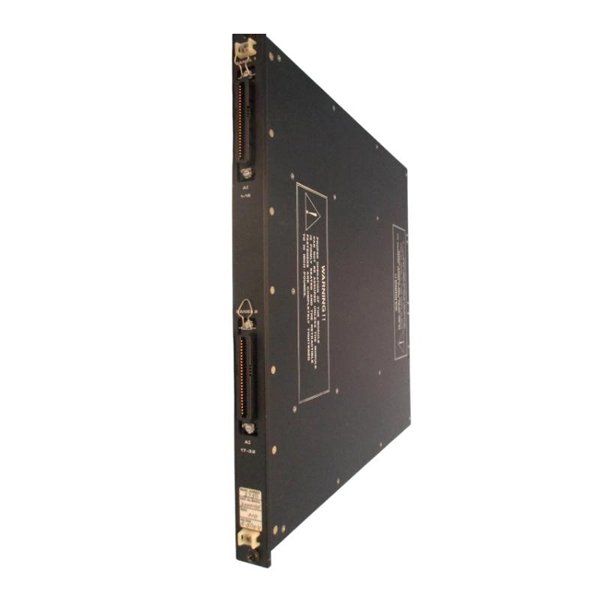

Triconex 3526 Analog Input Module

Manufacturer:Triconex

Product Number:3526

Product Type:Analog Input Module

Origin:USA

Dimensions:320 × 250 × 60 mm

Weight:1.2 kg

Views:113

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 3526 Analog Input Module is a precision-engineered module designed to acquire analog signals from field devices and transmit them securely into the Triconex control system. This module plays a critical role in process industries where accurate, continuous monitoring of temperature, pressure, flow, or other process variables is required.

It converts analog signals such as 4–20 mA, 0–10 V, or thermocouple/RTD inputs into digital data for processing by the Triconex system. The 3526 ensures high accuracy, channel isolation, and noise immunity, making it suitable for both safety-critical and non-safety applications. With its robust design and compliance with safety standards, it is frequently deployed in Safety Instrumented Systems (SIS), Emergency Shutdown Systems (ESD), and Fire & Gas Systems (F&G).

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3526 |

| Device Type | Analog Input Module |

| Function | Acquisition and digitization of analog field signals |

| Input Signal Types | 4–20 mA, 0–10 V, Thermocouples, RTDs |

| Resolution | 12-bit to 16-bit depending on configuration |

| Accuracy | ±0.1% of full scale |

| Number of Channels | 16 isolated input channels |

| Isolation | Channel-to-channel and channel-to-system |

| Sampling Rate | Configurable, optimized for process control |

| Diagnostics | Built-in self-test and fault detection |

| Power Supply Requirement | 24 VDC nominal |

| Operating Voltage | Low-voltage analog inputs |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Fire Resistance | Flame-retardant PCB and housing |

| Mechanical Strength | Resistant to vibration and mechanical stress |

| Dimensions (W x H x D) | 320 × 250 × 60 mm |

| Weight | 1.2 kg |

| Certifications | CE, UL, IEC, TÜV certified for SIS use |

Applications

The Triconex 3526 Analog Input Module is applied in a wide variety of industrial systems where accurate signal acquisition is essential:

Safety Instrumented Systems (SIS) – For continuous monitoring of analog process signals.

Emergency Shutdown Systems (ESD) – Provides reliable input data to trigger shutdowns.

Fire and Gas Systems (F&G) – Acquires sensor data from detectors and transmitters.

Process Automation – Supports closed-loop control with real-time analog inputs.

Oil, Gas, and Petrochemical Plants – For monitoring critical process conditions.

Power Generation – Captures analog signals from turbines, boilers, and auxiliaries.

Advantages

The Triconex 3526 Analog Input Module offers a wide range of advantages for demanding industrial operations:

High Accuracy – Ensures precise signal acquisition with minimal drift.

Wide Input Range – Supports multiple analog input standards (current, voltage, thermocouples, RTDs).

Channel Isolation – Prevents cross-channel interference, enhancing reliability.

Robust Design – Built to withstand vibration, temperature fluctuations, and noise.

Comprehensive Diagnostics – Features fault detection and self-testing functions.

Safety Compliance – Certified for SIS, ensuring reliability in critical systems.

Ease of Integration – Seamlessly integrates with Triconex backplanes and terminal panels.

Long-Term Reliability – Reduced maintenance due to durable construction and stable performance.

FAQ

What types of analog signals can the 3526 module process?

It supports 4–20 mA, 0–10 V, thermocouples, and RTDs.

How many channels are available on the 3526 module?

The module provides 16 isolated analog input channels.

Does the module provide input isolation?

Yes, it offers channel-to-channel and channel-to-system isolation.

What is the resolution of the analog inputs?

It provides 12-bit to 16-bit resolution depending on configuration.

How does the module handle input signal noise?

It uses EMI/RFI shielding and isolation techniques to reduce interference.

Is the 3526 module suitable for safety instrumented systems?

Yes, it is TÜV-certified and commonly used in SIS applications.

Can the module perform self-diagnostics?

Yes, it includes built-in diagnostics for signal validation and fault detection.

What is the maximum operating temperature range?

It operates between -20°C and +70°C.

Can the 3526 support both redundant and standalone system architectures?

Yes, it integrates seamlessly into both configurations.

Does the module support fast sampling for dynamic process monitoring?

Yes, the sampling rate is configurable to suit process requirements.

Triconex 3526 Analog Input Module

Manufacturer:Triconex

Product Number:3526

Product Type:Analog Input Module

Origin:USA

Dimensions:320 × 250 × 60 mm

Weight:1.2 kg

Views:113

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Triconex 3526 Analog Input Module is a precision-engineered module designed to acquire analog signals from field devices and transmit them securely into the Triconex control system. This module plays a critical role in process industries where accurate, continuous monitoring of temperature, pressure, flow, or other process variables is required.

It converts analog signals such as 4–20 mA, 0–10 V, or thermocouple/RTD inputs into digital data for processing by the Triconex system. The 3526 ensures high accuracy, channel isolation, and noise immunity, making it suitable for both safety-critical and non-safety applications. With its robust design and compliance with safety standards, it is frequently deployed in Safety Instrumented Systems (SIS), Emergency Shutdown Systems (ESD), and Fire & Gas Systems (F&G).

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3526 |

| Device Type | Analog Input Module |

| Function | Acquisition and digitization of analog field signals |

| Input Signal Types | 4–20 mA, 0–10 V, Thermocouples, RTDs |

| Resolution | 12-bit to 16-bit depending on configuration |

| Accuracy | ±0.1% of full scale |

| Number of Channels | 16 isolated input channels |

| Isolation | Channel-to-channel and channel-to-system |

| Sampling Rate | Configurable, optimized for process control |

| Diagnostics | Built-in self-test and fault detection |

| Power Supply Requirement | 24 VDC nominal |

| Operating Voltage | Low-voltage analog inputs |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH, non-condensing |

| Fire Resistance | Flame-retardant PCB and housing |

| Mechanical Strength | Resistant to vibration and mechanical stress |

| Dimensions (W x H x D) | 320 × 250 × 60 mm |

| Weight | 1.2 kg |

| Certifications | CE, UL, IEC, TÜV certified for SIS use |

Applications

The Triconex 3526 Analog Input Module is applied in a wide variety of industrial systems where accurate signal acquisition is essential:

Safety Instrumented Systems (SIS) – For continuous monitoring of analog process signals.

Emergency Shutdown Systems (ESD) – Provides reliable input data to trigger shutdowns.

Fire and Gas Systems (F&G) – Acquires sensor data from detectors and transmitters.

Process Automation – Supports closed-loop control with real-time analog inputs.

Oil, Gas, and Petrochemical Plants – For monitoring critical process conditions.

Power Generation – Captures analog signals from turbines, boilers, and auxiliaries.

Advantages

The Triconex 3526 Analog Input Module offers a wide range of advantages for demanding industrial operations:

High Accuracy – Ensures precise signal acquisition with minimal drift.

Wide Input Range – Supports multiple analog input standards (current, voltage, thermocouples, RTDs).

Channel Isolation – Prevents cross-channel interference, enhancing reliability.

Robust Design – Built to withstand vibration, temperature fluctuations, and noise.

Comprehensive Diagnostics – Features fault detection and self-testing functions.

Safety Compliance – Certified for SIS, ensuring reliability in critical systems.

Ease of Integration – Seamlessly integrates with Triconex backplanes and terminal panels.

Long-Term Reliability – Reduced maintenance due to durable construction and stable performance.

FAQ

What types of analog signals can the 3526 module process?

It supports 4–20 mA, 0–10 V, thermocouples, and RTDs.

How many channels are available on the 3526 module?

The module provides 16 isolated analog input channels.

Does the module provide input isolation?

Yes, it offers channel-to-channel and channel-to-system isolation.

What is the resolution of the analog inputs?

It provides 12-bit to 16-bit resolution depending on configuration.

How does the module handle input signal noise?

It uses EMI/RFI shielding and isolation techniques to reduce interference.

Is the 3526 module suitable for safety instrumented systems?

Yes, it is TÜV-certified and commonly used in SIS applications.

Can the module perform self-diagnostics?

Yes, it includes built-in diagnostics for signal validation and fault detection.

What is the maximum operating temperature range?

It operates between -20°C and +70°C.

Can the 3526 support both redundant and standalone system architectures?

Yes, it integrates seamlessly into both configurations.

Does the module support fast sampling for dynamic process monitoring?

Yes, the sampling rate is configurable to suit process requirements.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...