Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

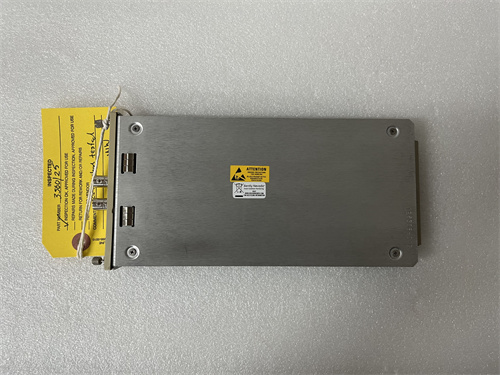

Bently Nevada 3500/42M Vibration Monitoring Module

Module Number:3500/42M

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The BENTLY 3500/42M module is a vibration monitoring module launched by Bentley Nevada, mainly used to monitor and analyze the vibration situation of industrial equipment, in order to improve the reliability and safety of the equipment. The following is a detailed introduction to this module.

Main functions and characteristics

Used to monitor the vibration level of rotating machinery equipment (such as engines, pumps, compressors, etc.) to evaluate the operational status of the equipment.

It may support multi-channel vibration monitoring, which can simultaneously monitor the vibration situation of multiple devices or bearings.

Real time monitoring:

Equipped with real-time monitoring function, it can continuously monitor the vibration of equipment and provide real-time data feedback.

Spectrum analysis:

It may support spectrum analysis function, which can perform spectrum analysis on vibration data, identify fault frequencies and abnormal vibration modes.

Alarm function:

When the device vibration exceeds the set threshold, an alarm function may be triggered to remind operators to pay attention to the abnormal situation of the device.

Historical data records:

It may have a historical data recording function, which can record vibration data and save historical records for subsequent analysis and fault diagnosis.

It may support communication with other monitoring systems or data collection systems for data sharing and integration. For example, it supports multiple communication protocols and interfaces, such as Ethernet, serial communication (such as RS-232 and RS-485), and fieldbus interfaces (such as Profibus and Modbus).

Industrial grade design:

Durable industrial grade design, suitable for long-term use under harsh industrial environmental conditions.

Technical parameters

Measurement range: 0-5 g

Resolution: 0.01 g

Sampling frequency: 10 kHz

Output: BNC interface, analog signal output

Power supply: Powered by connecting to the acquisition system or external battery

Working temperature range: -18 ° C to+60 ° C

Storage temperature range: -40 ° C to+85 ° C

Dimensions: 97mm long x 45mm wide x 24mm high

Application scenarios

The BENTLY 3500/42M module is widely used in various industrial fields, such as petroleum, chemical, power, metallurgy, etc. It is used to monitor the vibration situation of rotating machinery equipment in real time, help users detect abnormal vibrations of equipment early, and take corresponding maintenance and upkeep measures to ensure the safe operation of equipment and extend its service life.

Summary

The BENTLY 3500/42M module, as a high-performance vibration monitoring module, plays an important role in the field of industrial equipment monitoring with its comprehensive monitoring functions, high-precision measurement capabilities, real-time data feedback, and powerful data communication capabilities. By using this module, users can achieve comprehensive monitoring and analysis of industrial equipment vibration, improve equipment reliability and safety, reduce failure rates and maintenance costs.

Bently Nevada 3500/42M Vibration Monitoring Module

Module Number:3500/42M

Product status:Discontinued

Delivery time:In stock

Product status:100% new

Sales country:All over the world

Product situation:one year warranty

Product Description

The BENTLY 3500/42M module is a vibration monitoring module launched by Bentley Nevada, mainly used to monitor and analyze the vibration situation of industrial equipment, in order to improve the reliability and safety of the equipment. The following is a detailed introduction to this module.

Main functions and characteristics

Used to monitor the vibration level of rotating machinery equipment (such as engines, pumps, compressors, etc.) to evaluate the operational status of the equipment.

It may support multi-channel vibration monitoring, which can simultaneously monitor the vibration situation of multiple devices or bearings.

Real time monitoring:

Equipped with real-time monitoring function, it can continuously monitor the vibration of equipment and provide real-time data feedback.

Spectrum analysis:

It may support spectrum analysis function, which can perform spectrum analysis on vibration data, identify fault frequencies and abnormal vibration modes.

Alarm function:

When the device vibration exceeds the set threshold, an alarm function may be triggered to remind operators to pay attention to the abnormal situation of the device.

Historical data records:

It may have a historical data recording function, which can record vibration data and save historical records for subsequent analysis and fault diagnosis.

It may support communication with other monitoring systems or data collection systems for data sharing and integration. For example, it supports multiple communication protocols and interfaces, such as Ethernet, serial communication (such as RS-232 and RS-485), and fieldbus interfaces (such as Profibus and Modbus).

Industrial grade design:

Durable industrial grade design, suitable for long-term use under harsh industrial environmental conditions.

Technical parameters

Measurement range: 0-5 g

Resolution: 0.01 g

Sampling frequency: 10 kHz

Output: BNC interface, analog signal output

Power supply: Powered by connecting to the acquisition system or external battery

Working temperature range: -18 ° C to+60 ° C

Storage temperature range: -40 ° C to+85 ° C

Dimensions: 97mm long x 45mm wide x 24mm high

Application scenarios

The BENTLY 3500/42M module is widely used in various industrial fields, such as petroleum, chemical, power, metallurgy, etc. It is used to monitor the vibration situation of rotating machinery equipment in real time, help users detect abnormal vibrations of equipment early, and take corresponding maintenance and upkeep measures to ensure the safe operation of equipment and extend its service life.

Summary

The BENTLY 3500/42M module, as a high-performance vibration monitoring module, plays an important role in the field of industrial equipment monitoring with its comprehensive monitoring functions, high-precision measurement capabilities, real-time data feedback, and powerful data communication capabilities. By using this module, users can achieve comprehensive monitoring and analysis of industrial equipment vibration, improve equipment reliability and safety, reduce failure rates and maintenance costs.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...