Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

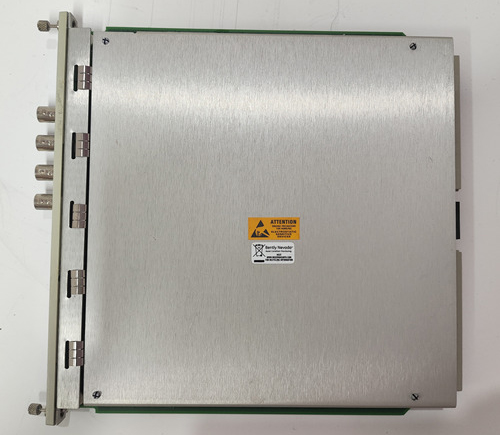

Bently Nevada 330101-30-60-90-02 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330101-30-60-90-02

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:9 meters

Weight:2.907 kg

Views:88

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-30-60-90-02 is a high-precision 8mm proximity probe from the 3300 XL Proximity Transducer System, designed for monitoring critical rotating machinery. Its main function is to measure shaft vibration and axial displacement with high accuracy, providing essential data for machinery protection systems and condition monitoring.

This model features an extended total length of 9 meters and a robust design that ensures accurate measurements in challenging industrial environments, such as power generation, petrochemical, oil & gas, and heavy industrial applications. By integrating this probe into machinery monitoring systems, operators can detect rotor imbalances, misalignment, and other dynamic issues early, thereby reducing the risk of catastrophic failures and unplanned downtime.

The probe is designed according to API 670 standards, ensuring compliance with global machinery protection requirements and offering reliable, repeatable performance under extreme temperatures, high vibration, and harsh environmental conditions.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330101-30-60-90-02 |

| Series | 3300 XL 8mm Proximity Transducer System |

| Probe Tip Diameter | 8 mm |

| Total Length | 9.0 meters |

| Connector Type | Microdot |

| Operating Temperature | -35°C to +177°C |

| Housing Material | Stainless Steel |

| Nominal Gap | 2.0 mm (80 mils) |

| Linear Range | 2.0 mm to 4.0 mm |

| Output Sensitivity | 7.87 V/mm (200 mV/mil) |

| Frequency Response | 0 to 10 kHz |

| Insulation Resistance | > 100 MΩ at 500 VDC |

| Compliance | API 670 |

| Probe Tip Length | 80 mm |

| Weight | 2.907 kg |

Product Applications

The 330101-30-60-90-02 is suitable for high-demand industrial applications, including:

Steam and Gas Turbines: Measuring rotor axial displacement and vibration to ensure safe, continuous operation.

Compressors: Monitoring rotor dynamics, detecting imbalance and misalignment early to prevent failure.

Pumps: Providing precise shaft vibration and position data for predictive maintenance.

Generators: Ensuring stable operation and preventing rotor faults in power generation applications.

Industrial Fans and Blowers: Measuring runout and vibration to maintain process efficiency.

Petrochemical and Oil & Gas Equipment: Supporting continuous machinery monitoring under high temperature and hazardous conditions.

Product Advantages

API 670 Compliance: Meets international standards for machinery protection and vibration monitoring.

Long Cable Length: 9 meters total length enables flexible placement and connection to monitoring systems.

Robust Construction: Stainless steel housing ensures resistance to corrosion, mechanical stress, and harsh environments.

Wide Temperature Range: Operates reliably from -35°C to +177°C.

High Signal Accuracy: Low noise and precise output for reliable machinery protection.

Seamless Integration: Compatible with Bently Nevada 3300 XL Proximitor sensors and monitoring systems.

Proven Industrial Reliability: Trusted globally for predictive maintenance and condition monitoring of critical rotating machinery.

FAQ

What is the output sensitivity of this probe?

The output sensitivity is 7.87 V/mm (200 mV/mil), providing precise and reliable measurements of shaft vibration and displacement for high-speed machinery monitoring.

What is the nominal gap for this probe?

The nominal gap is 2.0 mm (80 mils), ensuring linear and accurate signal output under normal operating conditions.

What is the linear measurement range?

The linear range is 2.0 mm to 4.0 mm, allowing precise measurement of shaft movement within the recommended operational window.

What is the frequency response of this probe?

The frequency response is 0 to 10 kHz, capable of detecting high-speed rotor dynamics and transient vibration signals accurately.

Can this probe operate in hazardous environments?

Yes, it is fully API 670 compliant and suitable for operation in hazardous and high-temperature industrial environments, including petrochemical and oil & gas facilities.

What type of connector does the probe use?

The probe uses a Microdot connector for secure, low-noise signal transmission in industrial settings.

Is this probe compatible with 3300 XL Proximitor sensors?

Yes, it integrates seamlessly with Bently Nevada 3300 XL Proximitor sensors without requiring modifications or adapters.

What is the insulation resistance of the probe?

The insulation resistance is greater than 100 MΩ at 500 VDC, ensuring reliable electrical isolation for stable signal output.

What is the maximum operating temperature for this probe?

The maximum operating temperature is +177°C, allowing reliable operation in high-heat industrial machinery applications.

Does this probe comply with API 670 standards?

Yes, this probe fully meets API 670 requirements, providing reliable machinery protection and consistent monitoring for critical rotating equipment.

Bently Nevada 330101-30-60-90-02 3300 XL 8mm Proximity Probes

Manufacturer:Bently Nevada

Product Number:330101-30-60-90-02

Product Type:3300 XL 8mm Proximity Probes

Origin:USA

Total Length:9 meters

Weight:2.907 kg

Views:88

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330101-30-60-90-02 is a high-precision 8mm proximity probe from the 3300 XL Proximity Transducer System, designed for monitoring critical rotating machinery. Its main function is to measure shaft vibration and axial displacement with high accuracy, providing essential data for machinery protection systems and condition monitoring.

This model features an extended total length of 9 meters and a robust design that ensures accurate measurements in challenging industrial environments, such as power generation, petrochemical, oil & gas, and heavy industrial applications. By integrating this probe into machinery monitoring systems, operators can detect rotor imbalances, misalignment, and other dynamic issues early, thereby reducing the risk of catastrophic failures and unplanned downtime.

The probe is designed according to API 670 standards, ensuring compliance with global machinery protection requirements and offering reliable, repeatable performance under extreme temperatures, high vibration, and harsh environmental conditions.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 330101-30-60-90-02 |

| Series | 3300 XL 8mm Proximity Transducer System |

| Probe Tip Diameter | 8 mm |

| Total Length | 9.0 meters |

| Connector Type | Microdot |

| Operating Temperature | -35°C to +177°C |

| Housing Material | Stainless Steel |

| Nominal Gap | 2.0 mm (80 mils) |

| Linear Range | 2.0 mm to 4.0 mm |

| Output Sensitivity | 7.87 V/mm (200 mV/mil) |

| Frequency Response | 0 to 10 kHz |

| Insulation Resistance | > 100 MΩ at 500 VDC |

| Compliance | API 670 |

| Probe Tip Length | 80 mm |

| Weight | 2.907 kg |

Product Applications

The 330101-30-60-90-02 is suitable for high-demand industrial applications, including:

Steam and Gas Turbines: Measuring rotor axial displacement and vibration to ensure safe, continuous operation.

Compressors: Monitoring rotor dynamics, detecting imbalance and misalignment early to prevent failure.

Pumps: Providing precise shaft vibration and position data for predictive maintenance.

Generators: Ensuring stable operation and preventing rotor faults in power generation applications.

Industrial Fans and Blowers: Measuring runout and vibration to maintain process efficiency.

Petrochemical and Oil & Gas Equipment: Supporting continuous machinery monitoring under high temperature and hazardous conditions.

Product Advantages

API 670 Compliance: Meets international standards for machinery protection and vibration monitoring.

Long Cable Length: 9 meters total length enables flexible placement and connection to monitoring systems.

Robust Construction: Stainless steel housing ensures resistance to corrosion, mechanical stress, and harsh environments.

Wide Temperature Range: Operates reliably from -35°C to +177°C.

High Signal Accuracy: Low noise and precise output for reliable machinery protection.

Seamless Integration: Compatible with Bently Nevada 3300 XL Proximitor sensors and monitoring systems.

Proven Industrial Reliability: Trusted globally for predictive maintenance and condition monitoring of critical rotating machinery.

FAQ

What is the output sensitivity of this probe?

The output sensitivity is 7.87 V/mm (200 mV/mil), providing precise and reliable measurements of shaft vibration and displacement for high-speed machinery monitoring.

What is the nominal gap for this probe?

The nominal gap is 2.0 mm (80 mils), ensuring linear and accurate signal output under normal operating conditions.

What is the linear measurement range?

The linear range is 2.0 mm to 4.0 mm, allowing precise measurement of shaft movement within the recommended operational window.

What is the frequency response of this probe?

The frequency response is 0 to 10 kHz, capable of detecting high-speed rotor dynamics and transient vibration signals accurately.

Can this probe operate in hazardous environments?

Yes, it is fully API 670 compliant and suitable for operation in hazardous and high-temperature industrial environments, including petrochemical and oil & gas facilities.

What type of connector does the probe use?

The probe uses a Microdot connector for secure, low-noise signal transmission in industrial settings.

Is this probe compatible with 3300 XL Proximitor sensors?

Yes, it integrates seamlessly with Bently Nevada 3300 XL Proximitor sensors without requiring modifications or adapters.

What is the insulation resistance of the probe?

The insulation resistance is greater than 100 MΩ at 500 VDC, ensuring reliable electrical isolation for stable signal output.

What is the maximum operating temperature for this probe?

The maximum operating temperature is +177°C, allowing reliable operation in high-heat industrial machinery applications.

Does this probe comply with API 670 standards?

Yes, this probe fully meets API 670 requirements, providing reliable machinery protection and consistent monitoring for critical rotating equipment.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...