Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

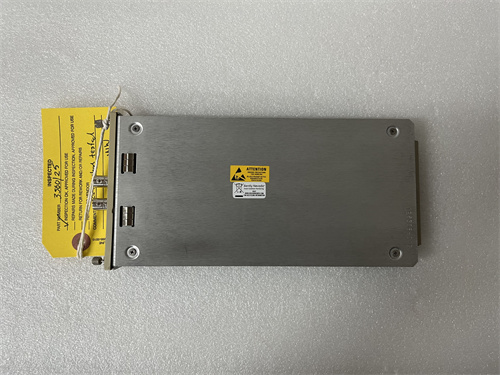

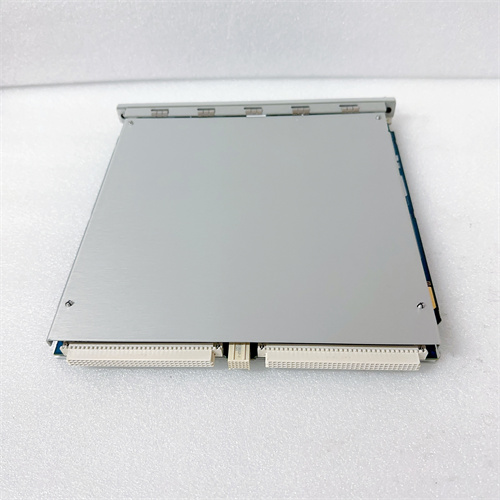

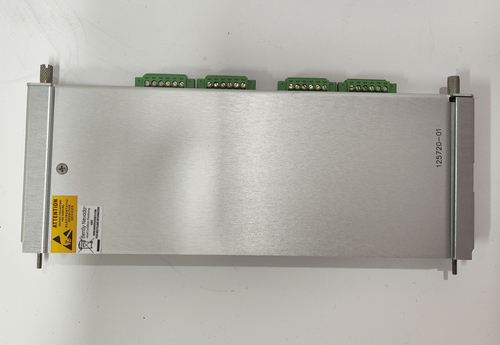

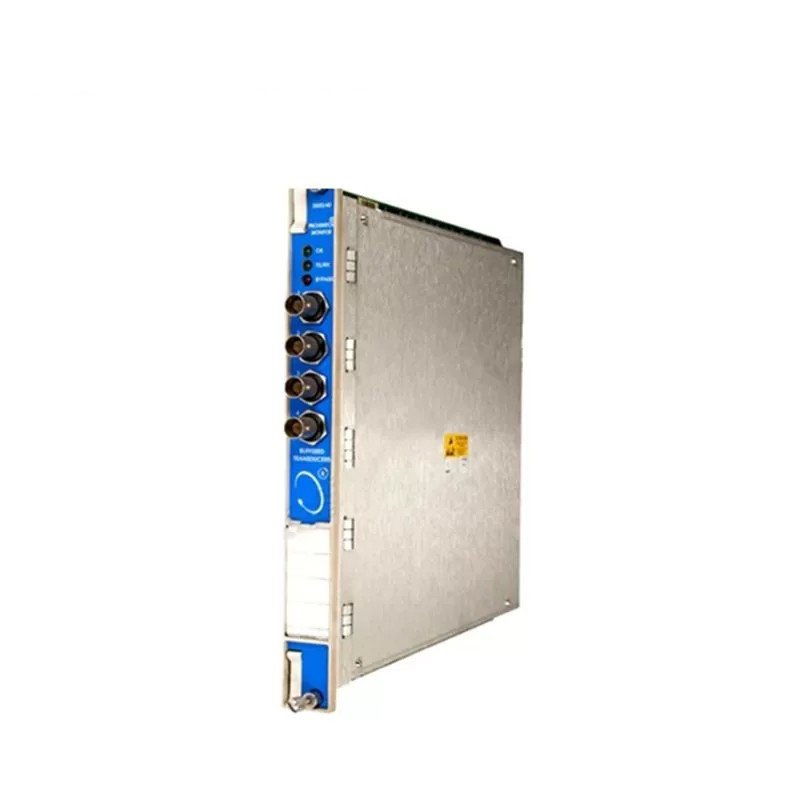

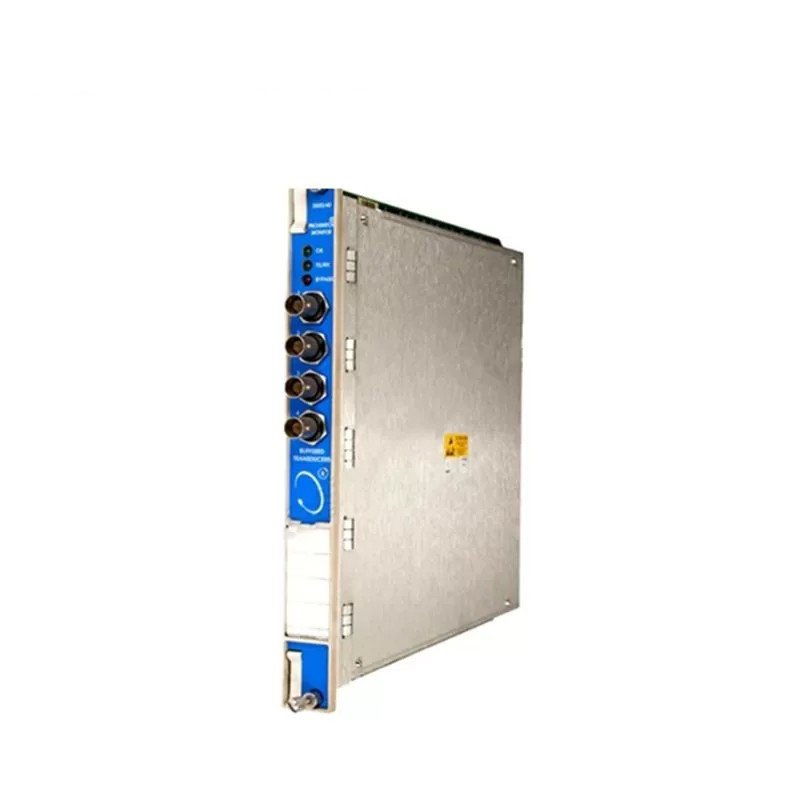

Bently Nevada 138700-01 I/O Module

Brand:Bently Nevada

Model Number:138700-01

Type:I/O Module

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:155 x 136 x 119 mm

Weight:280g

Price:USD500

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 138700-01 is a specialized I/O module designed for the Bently Nevada 3500/42 monitoring system. This module plays a crucial role in acquiring and processing data related to the absolute position of a rotating shaft.

Key Functions

- Data Acquisition: The module collects precise angular position data of a shaft, which is essential for diagnostic and monitoring applications.

- Signal Conditioning: It processes raw signals from sensors, ensuring they are in a suitable format for further analysis.

- Communication: The module interfaces with the 3500/42 system, transmitting acquired data for storage, analysis, and potential alarm generation.

Technical Specifications

- Compatibility: The module is exclusively designed for the Bently Nevada 3500/42 system.

- Inputs: It accepts signals from various shaft position sensors, including resolvers and encoders.

- Outputs: The module provides processed data to the 3500/42 system, often in digital format.

- Accuracy: Designed to meet stringent tolerances, the module ensures high accuracy in shaft position measurements.

- Environmental: Built to withstand industrial environments, the module often carries certifications for temperature, humidity, and vibration resistance.

- Configuration: You can configure the module to meet specific application requirements, including scaling, filtering, and alarm thresholds.

Applications

- Rotating Machinery Monitoring: The module is widely used in monitoring turbines, compressors, and pumps.

- Vibration Analysis: It is essential for vibration analysis, helping to detect imbalances, misalignment, and other mechanical issues.

- Condition Monitoring: The module supports condition-based maintenance strategies, enhancing operational efficiency.

- Phase Measurement: It is also used for phase measurements between multiple rotating components, adding versatility to its applications.

Bently Nevada 138700-01 I/O Module

Brand:Bently Nevada

Model Number:138700-01

Type:I/O Module

Product Origin:USA

Payment:T/T, Western Union, Credit Card

Dimensions:155 x 136 x 119 mm

Weight:280g

Price:USD500

Certificate:CE

Warranty:1 years

Product Description

The Bently Nevada 138700-01 is a specialized I/O module designed for the Bently Nevada 3500/42 monitoring system. This module plays a crucial role in acquiring and processing data related to the absolute position of a rotating shaft.

Key Functions

- Data Acquisition: The module collects precise angular position data of a shaft, which is essential for diagnostic and monitoring applications.

- Signal Conditioning: It processes raw signals from sensors, ensuring they are in a suitable format for further analysis.

- Communication: The module interfaces with the 3500/42 system, transmitting acquired data for storage, analysis, and potential alarm generation.

Technical Specifications

- Compatibility: The module is exclusively designed for the Bently Nevada 3500/42 system.

- Inputs: It accepts signals from various shaft position sensors, including resolvers and encoders.

- Outputs: The module provides processed data to the 3500/42 system, often in digital format.

- Accuracy: Designed to meet stringent tolerances, the module ensures high accuracy in shaft position measurements.

- Environmental: Built to withstand industrial environments, the module often carries certifications for temperature, humidity, and vibration resistance.

- Configuration: You can configure the module to meet specific application requirements, including scaling, filtering, and alarm thresholds.

Applications

- Rotating Machinery Monitoring: The module is widely used in monitoring turbines, compressors, and pumps.

- Vibration Analysis: It is essential for vibration analysis, helping to detect imbalances, misalignment, and other mechanical issues.

- Condition Monitoring: The module supports condition-based maintenance strategies, enhancing operational efficiency.

- Phase Measurement: It is also used for phase measurements between multiple rotating components, adding versatility to its applications.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...