Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

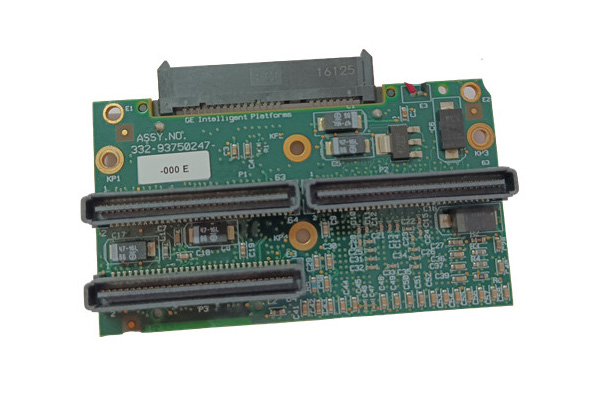

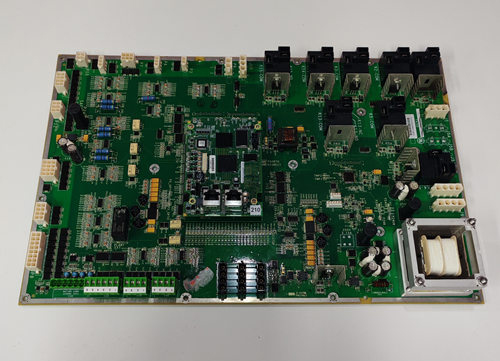

General Electric IC693APU302 Axis Positioning Module

Manufacturer:GE

Product Number:IC693APU302

Product Type:Axis Positioning Module

Origin:USA

Dimensions:64 x 127 x 102 mm

Weight:0.57 kg

Views:44

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IC693APU302 Axis Positioning Module is a high-performance motion control solution designed for industrial automation systems using the GE Series 90-30 PLC platform. It provides precise and reliable control for a single axis of motion, enabling coordinated movements in machinery that require tight synchronization and accuracy. This module integrates seamlessly with the GE 90-30 I/O rack and is ideal for applications involving stepper or servo motor control. Through a combination of pulse train output, position feedback, and flexible programming capabilities, it allows engineers to develop sophisticated motion profiles while maintaining system simplicity and modularity.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | IC693APU302 |

| Product Type | Axis Positioning Module |

| System Compatibility | GE Series 90-30 PLC |

| Number of Controlled Axis | 1 |

| Control Type | Pulse Train Output (PTO) |

| Position Feedback | Encoder Input (A/B quadrature, single-ended or differential) |

| Position Range | ±2,147,483,647 pulses (32-bit signed) |

| Maximum Pulse Rate | 1 MHz |

| Motor Types Supported | Stepper and Servo motors (open-loop or closed-loop) |

| Operating Voltage | 5V DC TTL (for pulse/dir and encoder signals) |

| Backplane Power Consumption | 5V DC, 700 mA typical |

| Diagnostics | Built-in error detection and status LEDs |

| Environmental Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Dimensions (W x H x D) | 64 x 127 x 102 mm |

| Weight | 0.57 kg |

| Mounting | DIN rail or panel mounting within Series 90-30 rack |

| Certifications | UL, CE, CSA |

Applications

The IC693APU302 Axis Positioning Module is widely used in industrial automation environments where precise movement and positioning are essential. Common application areas include:

Packaging machinery – controlling conveyor movements, robotic arms, and sealing equipment.

CNC machines – managing linear or rotary tool paths in machining centers.

Material handling systems – regulating lifts, sorting arms, and transfer mechanisms.

Pick-and-place robots – ensuring accurate positioning for small component assembly.

Printing and labeling machines – coordinating label placement and media feed.

Textile machinery – synchronizing tension rollers or fabric cutters.

Its versatility in both open-loop and closed-loop configurations makes it suitable for a broad range of motion control tasks.

Product Advantages

High Precision: Supports up to 1 MHz output rate for highly accurate motion control.

Integrated Feedback: Quadrature encoder feedback enables real-time position correction.

Scalable: Easily integrated into existing Series 90-30 PLC systems without extra hardware.

Flexible Control: Supports complex move profiles including acceleration, deceleration, and homing sequences.

Reliable Diagnostics: Onboard LEDs and diagnostic registers help quickly identify system faults.

Easy Programming: Configured via GE’s VersaPro or Proficy Machine Edition software.

Robust Design: Engineered to operate reliably in industrial environments with wide temperature tolerance and mechanical durability.

Low Footprint: Compact design conserves space in control panels.

Frequently Asked Questions (FAQ)

Q: What type of motors are compatible with IC693APU302?

A: It supports both stepper and servo motors using pulse train output.

Q: Can I use this module for closed-loop control?

A: Yes, it accepts encoder feedback for closed-loop motion applications.

Q: What software is used to configure IC693APU302?

A: You can use GE VersaPro or Proficy Machine Edition for configuration and programming.

Q: How many axes can one module control?

A: The module is designed for single-axis motion control.

Q: Does the IC693APU302 require external power?

A: It draws power from the backplane but needs external voltage for motor driver circuits.

Q: What is the maximum pulse frequency it can generate?

A: The module supports a pulse frequency of up to 1 MHz.

Q: How is feedback provided to the module?

A: Feedback is provided via A/B quadrature encoder signals.

Q: Is this module hot-swappable?

A: No, power should be turned off when installing or replacing the module.

Q: What kind of connector is used for encoder input?

A: It uses standard screw terminals or removable connectors depending on the rack system.

Q: Can I use the IC693APU302 in outdoor environments?

A: It is not rated for outdoor use; it must be installed in an enclosed, temperature-controlled environment.

General Electric IC693APU302 Axis Positioning Module

Manufacturer:GE

Product Number:IC693APU302

Product Type:Axis Positioning Module

Origin:USA

Dimensions:64 x 127 x 102 mm

Weight:0.57 kg

Views:44

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The GE IC693APU302 Axis Positioning Module is a high-performance motion control solution designed for industrial automation systems using the GE Series 90-30 PLC platform. It provides precise and reliable control for a single axis of motion, enabling coordinated movements in machinery that require tight synchronization and accuracy. This module integrates seamlessly with the GE 90-30 I/O rack and is ideal for applications involving stepper or servo motor control. Through a combination of pulse train output, position feedback, and flexible programming capabilities, it allows engineers to develop sophisticated motion profiles while maintaining system simplicity and modularity.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | IC693APU302 |

| Product Type | Axis Positioning Module |

| System Compatibility | GE Series 90-30 PLC |

| Number of Controlled Axis | 1 |

| Control Type | Pulse Train Output (PTO) |

| Position Feedback | Encoder Input (A/B quadrature, single-ended or differential) |

| Position Range | ±2,147,483,647 pulses (32-bit signed) |

| Maximum Pulse Rate | 1 MHz |

| Motor Types Supported | Stepper and Servo motors (open-loop or closed-loop) |

| Operating Voltage | 5V DC TTL (for pulse/dir and encoder signals) |

| Backplane Power Consumption | 5V DC, 700 mA typical |

| Diagnostics | Built-in error detection and status LEDs |

| Environmental Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% non-condensing |

| Dimensions (W x H x D) | 64 x 127 x 102 mm |

| Weight | 0.57 kg |

| Mounting | DIN rail or panel mounting within Series 90-30 rack |

| Certifications | UL, CE, CSA |

Applications

The IC693APU302 Axis Positioning Module is widely used in industrial automation environments where precise movement and positioning are essential. Common application areas include:

Packaging machinery – controlling conveyor movements, robotic arms, and sealing equipment.

CNC machines – managing linear or rotary tool paths in machining centers.

Material handling systems – regulating lifts, sorting arms, and transfer mechanisms.

Pick-and-place robots – ensuring accurate positioning for small component assembly.

Printing and labeling machines – coordinating label placement and media feed.

Textile machinery – synchronizing tension rollers or fabric cutters.

Its versatility in both open-loop and closed-loop configurations makes it suitable for a broad range of motion control tasks.

Product Advantages

High Precision: Supports up to 1 MHz output rate for highly accurate motion control.

Integrated Feedback: Quadrature encoder feedback enables real-time position correction.

Scalable: Easily integrated into existing Series 90-30 PLC systems without extra hardware.

Flexible Control: Supports complex move profiles including acceleration, deceleration, and homing sequences.

Reliable Diagnostics: Onboard LEDs and diagnostic registers help quickly identify system faults.

Easy Programming: Configured via GE’s VersaPro or Proficy Machine Edition software.

Robust Design: Engineered to operate reliably in industrial environments with wide temperature tolerance and mechanical durability.

Low Footprint: Compact design conserves space in control panels.

Frequently Asked Questions (FAQ)

Q: What type of motors are compatible with IC693APU302?

A: It supports both stepper and servo motors using pulse train output.

Q: Can I use this module for closed-loop control?

A: Yes, it accepts encoder feedback for closed-loop motion applications.

Q: What software is used to configure IC693APU302?

A: You can use GE VersaPro or Proficy Machine Edition for configuration and programming.

Q: How many axes can one module control?

A: The module is designed for single-axis motion control.

Q: Does the IC693APU302 require external power?

A: It draws power from the backplane but needs external voltage for motor driver circuits.

Q: What is the maximum pulse frequency it can generate?

A: The module supports a pulse frequency of up to 1 MHz.

Q: How is feedback provided to the module?

A: Feedback is provided via A/B quadrature encoder signals.

Q: Is this module hot-swappable?

A: No, power should be turned off when installing or replacing the module.

Q: What kind of connector is used for encoder input?

A: It uses standard screw terminals or removable connectors depending on the rack system.

Q: Can I use the IC693APU302 in outdoor environments?

A: It is not rated for outdoor use; it must be installed in an enclosed, temperature-controlled environment.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...