Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

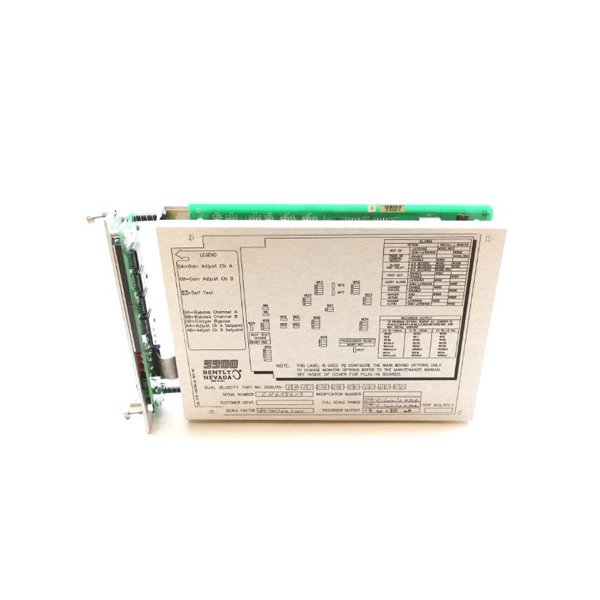

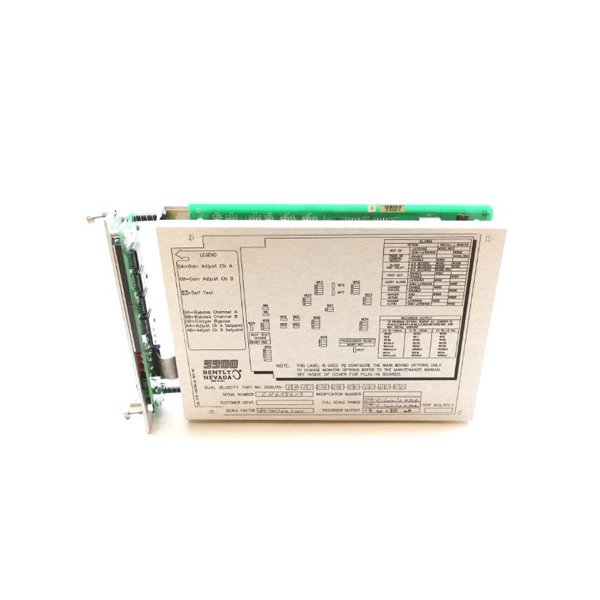

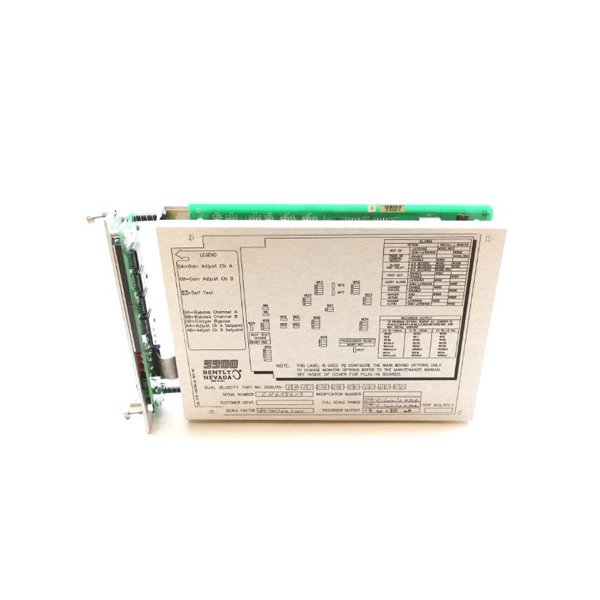

Bently Nevada 3300/55-04-01-08-08-00-00-00-00 Dual Velocity Monitor

Manufacturer:Bently Nevada

Product Number:3300/55-04-01-08-08-00-00-00-00

Product Type:Dual Velocity Monitor

Origin:USA

Vertical Dimension:83 mm

Weight:1 kg

Views:150

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300/55-04-01-08-08-00-00-00-00 Dual Velocity Monitor is a sophisticated device engineered for continuous, real-time monitoring of vibration velocity in rotating machinery. As a pivotal component of the renowned 3300 series, this monitor offers dual-channel inputs, allowing simultaneous assessment of two independent vibration signals. It is compatible with Velomitor® transducers, High Temperature Velomitor Systems (HTVS), and Velocity Seismoprobe® transducers, eliminating the need for additional interface modules. This flexibility ensures accurate detection of mechanical issues such as imbalance, misalignment, and looseness, facilitating proactive maintenance strategies.

Product Specifications

| Parameter | Details |

|---|---|

| Model | 3300/55-04-01-08-08-00-00-00-00 |

| Measurement Type | Dual-channel velocity monitoring |

| Input Types | Velomitor® transducers, HTVS, Velocity Seismoprobe® transducers |

| Sensitivity Options | 500 mV/in/s, 145 mV/in/s, 100 mV/in/s (jumper-programmable) |

| Frequency Response | 3 Hz to 10,000 Hz (-3 dB nominal) |

| Alarm Setpoints | Digitally adjustable from 0% to 100% of full-scale |

| Output Options | +4 to +20 mA, 0 to -10 Vdc, +1 to +5 Vdc |

| Power Consumption | Nominal 1.5 Watts |

| Operating Temperature | 0°C to +65°C (32°F to 150°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Relative Humidity | Up to 95%, non-condensing |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

Applications

The 3300/55 Dual Velocity Monitor is utilized across various industries for the protection and maintenance of critical rotating equipment:

Power Generation: Monitoring turbines and generators to detect early signs of vibration-related issues.

Oil & Gas: Ensuring the integrity of compressors and pumps in upstream and downstream operations.

Petrochemical: Overseeing the performance of rotating machinery in processing plants.

Manufacturing: Maintaining the health of motors, fans, and other rotating equipment on production lines.

Mining: Supervising crushers, conveyors, and other heavy-duty machinery for vibration anomalies.

Advantages

Dual-Channel Monitoring: Enables simultaneous assessment of two separate vibration signals, enhancing diagnostic capabilities.

Wide Frequency Response: Covers a broad spectrum, allowing detection of various vibration issues.

Flexible Sensitivity Settings: Accommodates different machinery types and operational conditions.

User-Selectable Filters: High- and low-pass filter options can be easily configured via plug-in jumpers.

Comprehensive Output Options: Provides multiple output formats for integration with diverse control systems.

Robust Alarm System: Digitally adjustable alarm setpoints facilitate timely alerts for preventive action.

Environmental Resilience: Designed to operate effectively across a range of temperatures and humidity levels.

FAQ

What is the primary function of the Bently Nevada 3300/55-04-01-08-08-00-00-00-00 Dual Velocity Monitor?

-

It provides continuous, real-time monitoring of vibration velocity in rotating machinery to detect and diagnose mechanical issues early.

-

Which transducers are compatible with this monitor?

-

It is compatible with Bently Nevada Velomitor® transducers, High Temperature Velomitor Systems (HTVS), and Velocity Seismoprobe® transducers.

-

What sensitivity options are available?

-

The monitor offers jumper-programmable sensitivity settings of 500 mV/in/s, 145 mV/in/s, and 100 mV/in/s.

-

What is the frequency response range of the monitor?

-

For Velocity Seismoprobe® transducers, the range is 3 Hz to 10,000 Hz (-3 dB nominal). For HTVS and Velomitor® transducers, it is 3 Hz to 3,000 Hz (-3 dB nominal).

-

How are alarm setpoints configured?

-

Both Alert and Danger alarms are digitally adjustable from 0% to 100% of full-scale, allowing customization based on specific monitoring requirements.

-

What output options does the monitor provide?

-

It offers recorder outputs that are user-programmable for +4 to +20 mA, 0 to -10 Vdc, or +1 to +5 Vdc, proportional to the programmed monitor full-scale.

-

Is the monitor suitable for harsh industrial environments?

-

Yes, it operates effectively within a temperature range of 0°C to +65°C (+32°F to +150°F) and can withstand relative humidity up to 95%, non-condensing.

-

What are the dimensions and weight of the monitor?

-

The monitor occupies one rack position and weighs 1 kg.

-

Can the monitor integrate with existing control systems?

-

Yes, its comprehensive output options facilitate seamless integration with various control and automation systems.

-

What maintenance is required for optimal performance?

-

Regular calibration checks and visual inspections are recommended to ensure the monitor functions correctly and provides accurate readings.

-

Bently Nevada 3300/55-04-01-08-08-00-00-00-00 Dual Velocity Monitor

Manufacturer:Bently Nevada

Product Number:3300/55-04-01-08-08-00-00-00-00

Product Type:Dual Velocity Monitor

Origin:USA

Vertical Dimension:83 mm

Weight:1 kg

Views:150

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300/55-04-01-08-08-00-00-00-00 Dual Velocity Monitor is a sophisticated device engineered for continuous, real-time monitoring of vibration velocity in rotating machinery. As a pivotal component of the renowned 3300 series, this monitor offers dual-channel inputs, allowing simultaneous assessment of two independent vibration signals. It is compatible with Velomitor® transducers, High Temperature Velomitor Systems (HTVS), and Velocity Seismoprobe® transducers, eliminating the need for additional interface modules. This flexibility ensures accurate detection of mechanical issues such as imbalance, misalignment, and looseness, facilitating proactive maintenance strategies.

Product Specifications

| Parameter | Details |

|---|---|

| Model | 3300/55-04-01-08-08-00-00-00-00 |

| Measurement Type | Dual-channel velocity monitoring |

| Input Types | Velomitor® transducers, HTVS, Velocity Seismoprobe® transducers |

| Sensitivity Options | 500 mV/in/s, 145 mV/in/s, 100 mV/in/s (jumper-programmable) |

| Frequency Response | 3 Hz to 10,000 Hz (-3 dB nominal) |

| Alarm Setpoints | Digitally adjustable from 0% to 100% of full-scale |

| Output Options | +4 to +20 mA, 0 to -10 Vdc, +1 to +5 Vdc |

| Power Consumption | Nominal 1.5 Watts |

| Operating Temperature | 0°C to +65°C (32°F to 150°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Relative Humidity | Up to 95%, non-condensing |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

Applications

The 3300/55 Dual Velocity Monitor is utilized across various industries for the protection and maintenance of critical rotating equipment:

Power Generation: Monitoring turbines and generators to detect early signs of vibration-related issues.

Oil & Gas: Ensuring the integrity of compressors and pumps in upstream and downstream operations.

Petrochemical: Overseeing the performance of rotating machinery in processing plants.

Manufacturing: Maintaining the health of motors, fans, and other rotating equipment on production lines.

Mining: Supervising crushers, conveyors, and other heavy-duty machinery for vibration anomalies.

Advantages

Dual-Channel Monitoring: Enables simultaneous assessment of two separate vibration signals, enhancing diagnostic capabilities.

Wide Frequency Response: Covers a broad spectrum, allowing detection of various vibration issues.

Flexible Sensitivity Settings: Accommodates different machinery types and operational conditions.

User-Selectable Filters: High- and low-pass filter options can be easily configured via plug-in jumpers.

Comprehensive Output Options: Provides multiple output formats for integration with diverse control systems.

Robust Alarm System: Digitally adjustable alarm setpoints facilitate timely alerts for preventive action.

Environmental Resilience: Designed to operate effectively across a range of temperatures and humidity levels.

FAQ

What is the primary function of the Bently Nevada 3300/55-04-01-08-08-00-00-00-00 Dual Velocity Monitor?

-

It provides continuous, real-time monitoring of vibration velocity in rotating machinery to detect and diagnose mechanical issues early.

-

Which transducers are compatible with this monitor?

-

It is compatible with Bently Nevada Velomitor® transducers, High Temperature Velomitor Systems (HTVS), and Velocity Seismoprobe® transducers.

-

What sensitivity options are available?

-

The monitor offers jumper-programmable sensitivity settings of 500 mV/in/s, 145 mV/in/s, and 100 mV/in/s.

-

What is the frequency response range of the monitor?

-

For Velocity Seismoprobe® transducers, the range is 3 Hz to 10,000 Hz (-3 dB nominal). For HTVS and Velomitor® transducers, it is 3 Hz to 3,000 Hz (-3 dB nominal).

-

How are alarm setpoints configured?

-

Both Alert and Danger alarms are digitally adjustable from 0% to 100% of full-scale, allowing customization based on specific monitoring requirements.

-

What output options does the monitor provide?

-

It offers recorder outputs that are user-programmable for +4 to +20 mA, 0 to -10 Vdc, or +1 to +5 Vdc, proportional to the programmed monitor full-scale.

-

Is the monitor suitable for harsh industrial environments?

-

Yes, it operates effectively within a temperature range of 0°C to +65°C (+32°F to +150°F) and can withstand relative humidity up to 95%, non-condensing.

-

What are the dimensions and weight of the monitor?

-

The monitor occupies one rack position and weighs 1 kg.

-

Can the monitor integrate with existing control systems?

-

Yes, its comprehensive output options facilitate seamless integration with various control and automation systems.

-

What maintenance is required for optimal performance?

-

Regular calibration checks and visual inspections are recommended to ensure the monitor functions correctly and provides accurate readings.

-

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...