Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

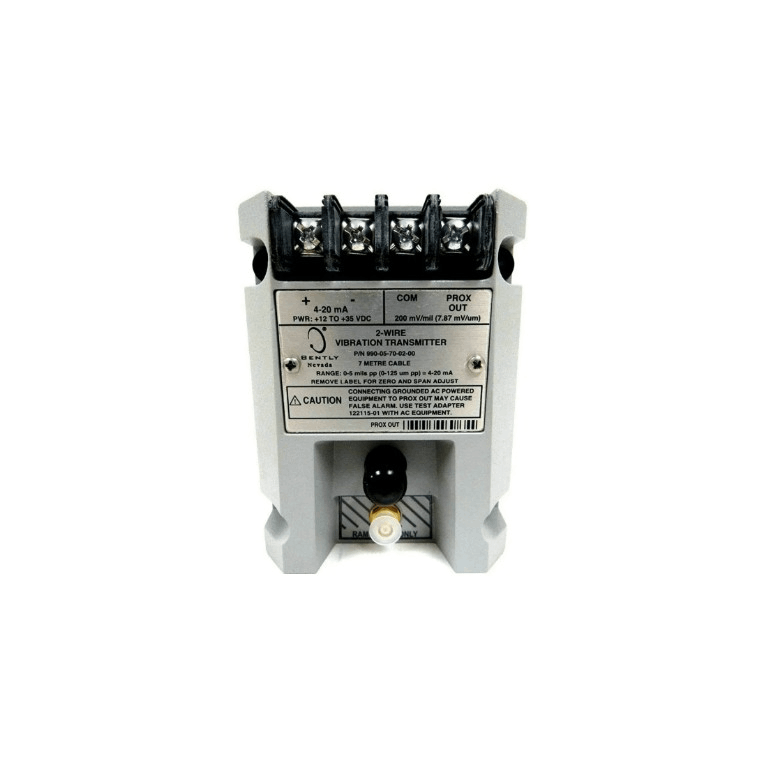

Bently Nevada 990-05-70-01-00 Vibration Transmitter

Item Number: 990-05-70-01-00

Brand: Bently Nevada

Lead Time: In stock

Description:Vibration Transmitter

Payment: T/T

Product Description

Bently Nevada 990-05-70-01-00 vibration transmitter is mainly aimed at original equipment manufacturers (OEMs) of centrifugal air compressors, small pumps, motors or fans. The transmitter mainly converts vibration signals into standard proportional signals and transmits them as input to the mechanical control system for equipment protection alarms and logic control.

Note: This transmitter is a two-wire, loop-powered device and must be used with the 3300 NSv proximity probe and its matching extension cable (5m and 7m system length options are available)

Function & Features

- Dynamic Signal Output: The 990-05-70-01-00 provides "PROX OUT" and "COM" non-isolated terminals, as well as a coaxial connector, to output dynamic vibration and gap voltage signals.

- Loop Adjustment: The 990-05-70-01-00 transmitter has non-interactive zero and span potentiometers under the label to support quick adjustment of the loop signal.

- Test and Protection Functions:

- The 990-05-70-01-00 has a test input pin that can input a signal through a function generator to quickly verify the loop signal output.

- The 990-05-70-01-00 has a "Not OK / Signal Suppression" circuit to prevent excessive output or false alarms caused by proximity probe failure or loose connections

Specifications

|

Parameter |

Details |

|

Model |

990-05-70-01-00 |

|

Input |

Accepts 1 non-contacting 3300 NSv Proximity Probe and extension cable. |

|

Power |

Requires +12 to +35 Vdc input at the transmitter terminal. |

|

Maximum loop resistance |

1,000 Ω including cable at 35 Vdc. |

|

Current limiting |

23 mA typical. |

|

Frequency response |

5 Hz to 6,000 Hz +0, 3 dB. |

|

Minimum target size |

9.5 mm (0.375 in) diameter. |

Bently Nevada 990-05-70-01-00 Vibration Transmitter

Item Number: 990-05-70-01-00

Brand: Bently Nevada

Lead Time: In stock

Description:Vibration Transmitter

Payment: T/T

Product Description

Bently Nevada 990-05-70-01-00 vibration transmitter is mainly aimed at original equipment manufacturers (OEMs) of centrifugal air compressors, small pumps, motors or fans. The transmitter mainly converts vibration signals into standard proportional signals and transmits them as input to the mechanical control system for equipment protection alarms and logic control.

Note: This transmitter is a two-wire, loop-powered device and must be used with the 3300 NSv proximity probe and its matching extension cable (5m and 7m system length options are available)

Function & Features

- Dynamic Signal Output: The 990-05-70-01-00 provides "PROX OUT" and "COM" non-isolated terminals, as well as a coaxial connector, to output dynamic vibration and gap voltage signals.

- Loop Adjustment: The 990-05-70-01-00 transmitter has non-interactive zero and span potentiometers under the label to support quick adjustment of the loop signal.

- Test and Protection Functions:

- The 990-05-70-01-00 has a test input pin that can input a signal through a function generator to quickly verify the loop signal output.

- The 990-05-70-01-00 has a "Not OK / Signal Suppression" circuit to prevent excessive output or false alarms caused by proximity probe failure or loose connections

Specifications

|

Parameter |

Details |

|

Model |

990-05-70-01-00 |

|

Input |

Accepts 1 non-contacting 3300 NSv Proximity Probe and extension cable. |

|

Power |

Requires +12 to +35 Vdc input at the transmitter terminal. |

|

Maximum loop resistance |

1,000 Ω including cable at 35 Vdc. |

|

Current limiting |

23 mA typical. |

|

Frequency response |

5 Hz to 6,000 Hz +0, 3 dB. |

|

Minimum target size |

9.5 mm (0.375 in) diameter. |

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...