Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

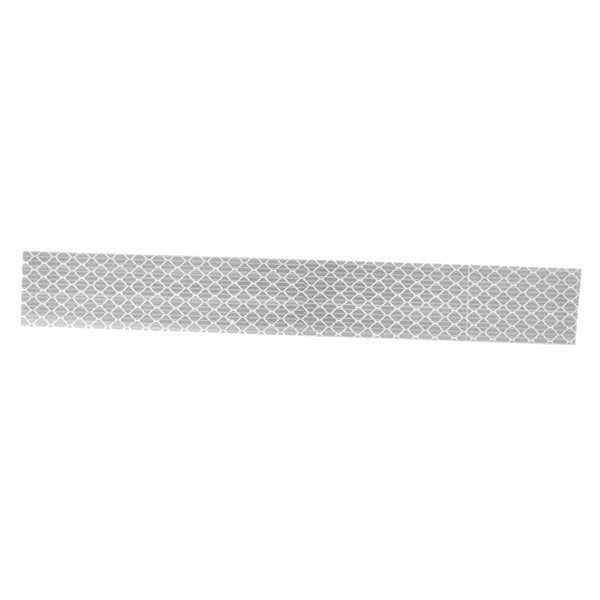

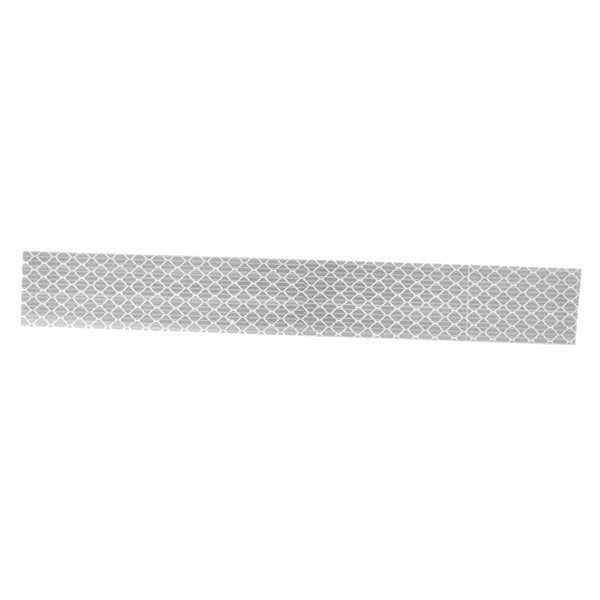

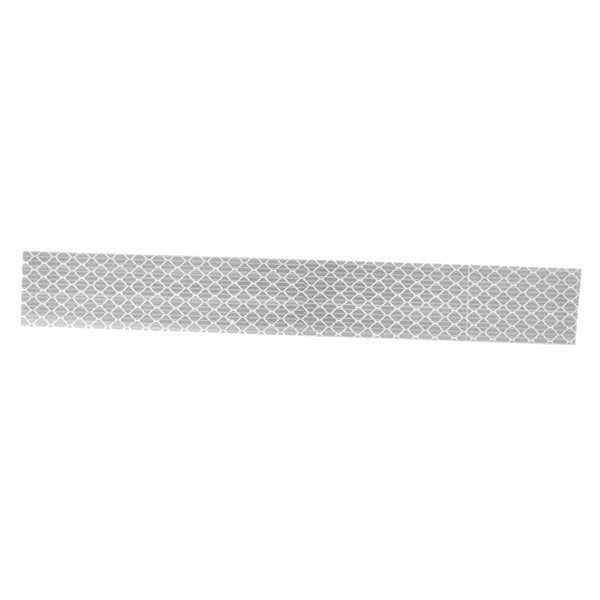

Bently Nevada 113M5529-01 Reflective Tape

Manufacturer:Bently Nevada

Product Number:113M5529-01

Product Type:Reflective Tape

Origin:USA

Length:0.6 meter

Weight:0.1 kg

Views:43

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 113M5529-01 Reflective Tape is a high-quality, industrial-grade reflective surface designed to enhance the performance of non-contact sensing systems, particularly photoelectric and optical proximity sensors used in machinery monitoring and diagnostics. Manufactured by Bently Nevada, a subsidiary of Baker Hughes, this reflective tape is widely adopted in critical industrial applications where precise rotational speed measurement and object detection are essential.

The tape is typically affixed to rotating shafts, pulleys, or flywheels, serving as a reliable target for laser tachometers, optical sensors, and speed probes. Its strong adhesion, high reflectivity, and resistance to oil, dust, and environmental contaminants make it a trusted accessory in demanding conditions.

Product Specifications

| Parameter | Value |

|---|---|

| Model Number | 113M5529-01 |

| Product Type | Reflective Tape |

| Application | Used for optical/tachometer sensing on rotating equipment |

| Adhesive Type | High-strength industrial pressure-sensitive adhesive |

| Reflectivity | High, suitable for laser and LED-based sensors |

| Material Type | Metalized polyester or vinyl with reflective coating |

| Color | Silver or white reflective surface |

| Length(per roll) | 0.6 meter |

| Tape Roll Width | 1.27 cm (0.5 in) standard |

| Temperature Range | -40°C to +80°C (-40°F to +176°F) |

| Weight (per roll) | 0.1 kg |

| Mounting Surface | Clean, dry metal or non-porous equipment surfaces |

Applications

The Bently Nevada 113M5529-01 Reflective Tape is widely used in various industrial settings. Its primary function is to act as a reflective target for non-contact sensors. Typical application areas include:

-

Rotational speed measurement on shafts, gears, rotors, and turbines

-

Optical sensing in motion detection systems

-

Laser tachometer targeting for machinery diagnostics

-

Temporary or permanent sensor targets during machine testing or monitoring

-

Condition monitoring on pumps, compressors, and motors

-

Predictive maintenance tasks involving vibration and rotational data capture

Product Advantages

-

High Reflectivity

Optimized to reflect both visible and infrared light, enhancing sensor signal reliability and consistency.

-

Durable Adhesion

The pressure-sensitive adhesive securely bonds to metal and other industrial surfaces without peeling under vibration.

-

Flexible Application

The tape can be easily cut into custom lengths and shapes to fit complex geometries or small-diameter shafts.

-

Environmentally Resistant

Designed to perform in harsh conditions, resisting oil, grease, moisture, and dust.

-

Non-Invasive Installation

Requires no mechanical alteration of equipment; applies directly to the surface with no special tools.

-

Versatile Compatibility

Compatible with Bently Nevada and third-party laser/optical sensors and tachometers.

Frequently Asked Questions (FAQ)

-

What is the primary function of the Bently Nevada 113M5529-01 Reflective Tape?

It serves as a reflective surface for optical or laser sensors to detect rotational speed or presence of moving parts.

-

Can it be used outdoors or in extreme temperatures?

Yes, it is rated for temperatures from -40°C to +80°C, making it suitable for many outdoor and harsh environments.

-

How should I prepare the surface before applying the tape?

Clean the surface thoroughly with alcohol or solvent to remove oil, dust, or moisture. Ensure it is dry before applying.

-

Is the tape reusable after removal?

No, the adhesive is designed for permanent bonding and may lose effectiveness if reapplied.

-

Does the tape interfere with metal detection or other sensors?

No, it is non-magnetic and electrically non-conductive, so it won’t interfere with other measurement systems.

-

Can the tape be cut to fit small surfaces?

Yes, it can be cut to desired lengths or widths using scissors or industrial blades.

-

Is this tape compatible with all Bently Nevada tachometers?

Yes, it is designed for optimal performance with Bently Nevada laser and photoelectric sensors.

-

What is the shelf life of the tape in storage?

Up to 2 years when stored in a cool, dry place in sealed packaging.

-

How long does it take to install the tape on equipment?

Typically under 5 minutes per application when the surface is properly cleaned.

-

What maintenance is required after application?

None; once applied, it requires no maintenance. However, periodic inspection is recommended in dusty or oily environments.

Bently Nevada 113M5529-01 Reflective Tape

Manufacturer:Bently Nevada

Product Number:113M5529-01

Product Type:Reflective Tape

Origin:USA

Length:0.6 meter

Weight:0.1 kg

Views:43

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 113M5529-01 Reflective Tape is a high-quality, industrial-grade reflective surface designed to enhance the performance of non-contact sensing systems, particularly photoelectric and optical proximity sensors used in machinery monitoring and diagnostics. Manufactured by Bently Nevada, a subsidiary of Baker Hughes, this reflective tape is widely adopted in critical industrial applications where precise rotational speed measurement and object detection are essential.

The tape is typically affixed to rotating shafts, pulleys, or flywheels, serving as a reliable target for laser tachometers, optical sensors, and speed probes. Its strong adhesion, high reflectivity, and resistance to oil, dust, and environmental contaminants make it a trusted accessory in demanding conditions.

Product Specifications

| Parameter | Value |

|---|---|

| Model Number | 113M5529-01 |

| Product Type | Reflective Tape |

| Application | Used for optical/tachometer sensing on rotating equipment |

| Adhesive Type | High-strength industrial pressure-sensitive adhesive |

| Reflectivity | High, suitable for laser and LED-based sensors |

| Material Type | Metalized polyester or vinyl with reflective coating |

| Color | Silver or white reflective surface |

| Length(per roll) | 0.6 meter |

| Tape Roll Width | 1.27 cm (0.5 in) standard |

| Temperature Range | -40°C to +80°C (-40°F to +176°F) |

| Weight (per roll) | 0.1 kg |

| Mounting Surface | Clean, dry metal or non-porous equipment surfaces |

Applications

The Bently Nevada 113M5529-01 Reflective Tape is widely used in various industrial settings. Its primary function is to act as a reflective target for non-contact sensors. Typical application areas include:

-

Rotational speed measurement on shafts, gears, rotors, and turbines

-

Optical sensing in motion detection systems

-

Laser tachometer targeting for machinery diagnostics

-

Temporary or permanent sensor targets during machine testing or monitoring

-

Condition monitoring on pumps, compressors, and motors

-

Predictive maintenance tasks involving vibration and rotational data capture

Product Advantages

-

High Reflectivity

Optimized to reflect both visible and infrared light, enhancing sensor signal reliability and consistency.

-

Durable Adhesion

The pressure-sensitive adhesive securely bonds to metal and other industrial surfaces without peeling under vibration.

-

Flexible Application

The tape can be easily cut into custom lengths and shapes to fit complex geometries or small-diameter shafts.

-

Environmentally Resistant

Designed to perform in harsh conditions, resisting oil, grease, moisture, and dust.

-

Non-Invasive Installation

Requires no mechanical alteration of equipment; applies directly to the surface with no special tools.

-

Versatile Compatibility

Compatible with Bently Nevada and third-party laser/optical sensors and tachometers.

Frequently Asked Questions (FAQ)

-

What is the primary function of the Bently Nevada 113M5529-01 Reflective Tape?

It serves as a reflective surface for optical or laser sensors to detect rotational speed or presence of moving parts.

-

Can it be used outdoors or in extreme temperatures?

Yes, it is rated for temperatures from -40°C to +80°C, making it suitable for many outdoor and harsh environments.

-

How should I prepare the surface before applying the tape?

Clean the surface thoroughly with alcohol or solvent to remove oil, dust, or moisture. Ensure it is dry before applying.

-

Is the tape reusable after removal?

No, the adhesive is designed for permanent bonding and may lose effectiveness if reapplied.

-

Does the tape interfere with metal detection or other sensors?

No, it is non-magnetic and electrically non-conductive, so it won’t interfere with other measurement systems.

-

Can the tape be cut to fit small surfaces?

Yes, it can be cut to desired lengths or widths using scissors or industrial blades.

-

Is this tape compatible with all Bently Nevada tachometers?

Yes, it is designed for optimal performance with Bently Nevada laser and photoelectric sensors.

-

What is the shelf life of the tape in storage?

Up to 2 years when stored in a cool, dry place in sealed packaging.

-

How long does it take to install the tape on equipment?

Typically under 5 minutes per application when the surface is properly cleaned.

-

What maintenance is required after application?

None; once applied, it requires no maintenance. However, periodic inspection is recommended in dusty or oily environments.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...