Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

Bently Nevada 3300/16-13-01-00-00-00-00 XY/Gap Dual Vibration Monitor

Manufacturer:Bently Nevada

Product Number:3300/16-13-01-00-00-00-00

Product Type:XY/Gap Dual Vibration Monitor

Origin:USA

Vertical Dimension:83 mm

Weight:1 kg

Views:170

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

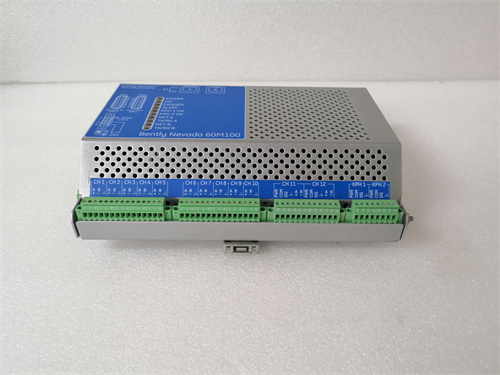

The Bently Nevada 3300/16-13-01-00-00-00-00 XY/Gap Dual Vibration Monitor is a high-performance monitoring system designed to measure and analyze vibration levels in rotating machinery. This dual-channel monitor is widely used in industrial applications to provide real-time vibration data, ensuring predictive maintenance and early fault detection.

This model is part of the Bently Nevada 3300 series, which is well known for its accuracy, reliability, and durability in harsh environments. It provides continuous monitoring of machine health by measuring both vibration displacement and gap voltage, which is essential for diagnosing potential equipment failures.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 3300/16-13-01-00-00-00-00 |

| Measurement Type | XY/Gap Dual Vibration |

| Number of Channels | 2 (Dual Channel) |

| Input Signal | Proximity Probe System |

| Measurement Range | 0 to 10 VDC |

| Frequency Response | 0.1 Hz to 10 kHz |

| Alarm Outputs | Configurable Relay Contacts |

| Communication Protocols | Compatible with Bently Nevada 3300 series systems |

| Operating Temperature | -30°C to +85°C |

| Power Supply | 24 VDC |

| Mounting Type | Rack-Mounted |

| Enclosure | Industrial-Grade, EMI Shielded |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

Applications

The Bently Nevada 3300/16-13-01-00-00-00-00 Dual Vibration Monitor is used in various industries for real-time vibration monitoring, including:

- Power Generation – Monitoring turbine vibration in thermal, nuclear, and hydroelectric power plants.

- Oil & Gas – Used in compressors, pumps, and drilling equipment for predictive maintenance.

- Chemical and Petrochemical Plants – Ensures the safety of rotating machinery by detecting early faults.

- Manufacturing and Heavy Machinery – Prevents unexpected downtime by providing early warnings of mechanical wear.

- Pulp and Paper Industry – Monitors vibration in rotating drums, presses, and motors.

- Steel and Metal Processing – Used for critical rotating equipment in rolling mills and furnaces.

Key Advantages

- High Accuracy – Provides precise vibration and gap measurements, allowing for early fault detection.

- Dual-Channel Monitoring – Capable of simultaneously monitoring two independent vibration points.

- Wide Frequency Response – Covers a broad range of vibration frequencies, making it suitable for various machinery types.

- Alarm and Relay Outputs – Configurable alarms for real-time failure alerts.

- Rugged Design – Built for industrial environments with EMI shielding for protection against electrical interference.

- Integration with Bently Nevada Systems – Seamlessly integrates with the Bently Nevada 3300 series for centralized monitoring.

- Predictive Maintenance Support – Reduces downtime and maintenance costs by detecting early signs of equipment failure.

Bently Nevada 3300/16-13-01-00-00-00-00 XY/Gap Dual Vibration Monitor

Manufacturer:Bently Nevada

Product Number:3300/16-13-01-00-00-00-00

Product Type:XY/Gap Dual Vibration Monitor

Origin:USA

Vertical Dimension:83 mm

Weight:1 kg

Views:170

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3300/16-13-01-00-00-00-00 XY/Gap Dual Vibration Monitor is a high-performance monitoring system designed to measure and analyze vibration levels in rotating machinery. This dual-channel monitor is widely used in industrial applications to provide real-time vibration data, ensuring predictive maintenance and early fault detection.

This model is part of the Bently Nevada 3300 series, which is well known for its accuracy, reliability, and durability in harsh environments. It provides continuous monitoring of machine health by measuring both vibration displacement and gap voltage, which is essential for diagnosing potential equipment failures.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | 3300/16-13-01-00-00-00-00 |

| Measurement Type | XY/Gap Dual Vibration |

| Number of Channels | 2 (Dual Channel) |

| Input Signal | Proximity Probe System |

| Measurement Range | 0 to 10 VDC |

| Frequency Response | 0.1 Hz to 10 kHz |

| Alarm Outputs | Configurable Relay Contacts |

| Communication Protocols | Compatible with Bently Nevada 3300 series systems |

| Operating Temperature | -30°C to +85°C |

| Power Supply | 24 VDC |

| Mounting Type | Rack-Mounted |

| Enclosure | Industrial-Grade, EMI Shielded |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

Applications

The Bently Nevada 3300/16-13-01-00-00-00-00 Dual Vibration Monitor is used in various industries for real-time vibration monitoring, including:

- Power Generation – Monitoring turbine vibration in thermal, nuclear, and hydroelectric power plants.

- Oil & Gas – Used in compressors, pumps, and drilling equipment for predictive maintenance.

- Chemical and Petrochemical Plants – Ensures the safety of rotating machinery by detecting early faults.

- Manufacturing and Heavy Machinery – Prevents unexpected downtime by providing early warnings of mechanical wear.

- Pulp and Paper Industry – Monitors vibration in rotating drums, presses, and motors.

- Steel and Metal Processing – Used for critical rotating equipment in rolling mills and furnaces.

Key Advantages

- High Accuracy – Provides precise vibration and gap measurements, allowing for early fault detection.

- Dual-Channel Monitoring – Capable of simultaneously monitoring two independent vibration points.

- Wide Frequency Response – Covers a broad range of vibration frequencies, making it suitable for various machinery types.

- Alarm and Relay Outputs – Configurable alarms for real-time failure alerts.

- Rugged Design – Built for industrial environments with EMI shielding for protection against electrical interference.

- Integration with Bently Nevada Systems – Seamlessly integrates with the Bently Nevada 3300 series for centralized monitoring.

- Predictive Maintenance Support – Reduces downtime and maintenance costs by detecting early signs of equipment failure.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...