Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

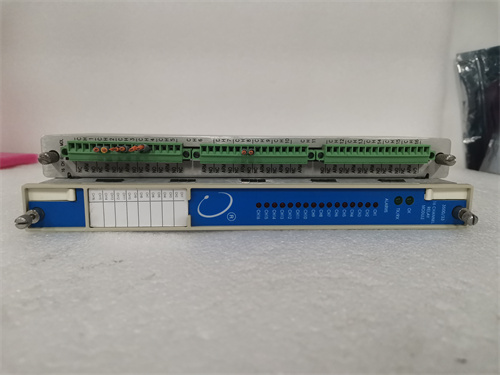

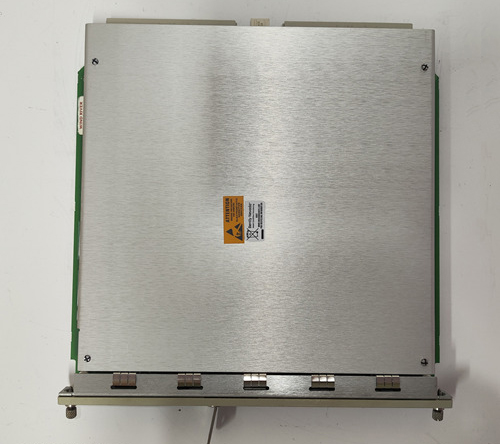

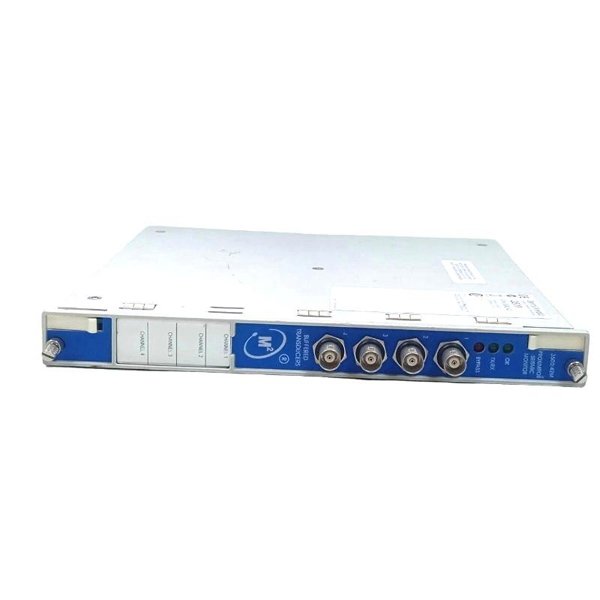

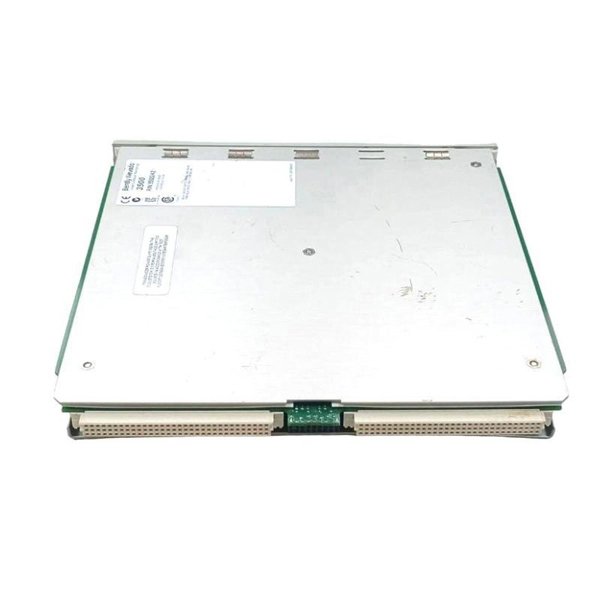

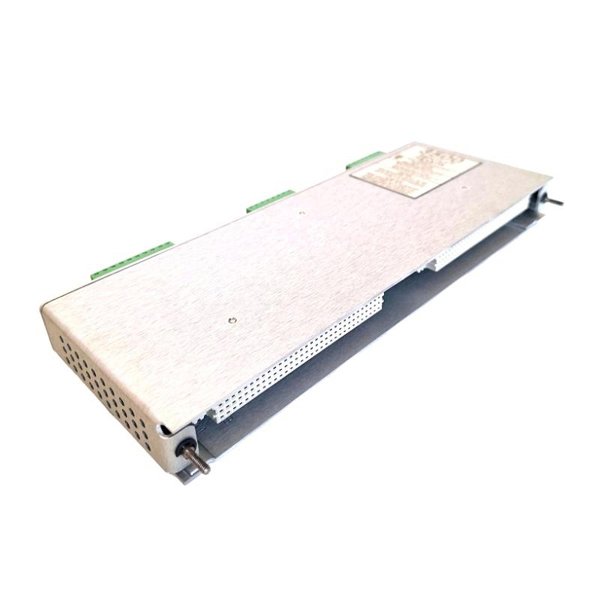

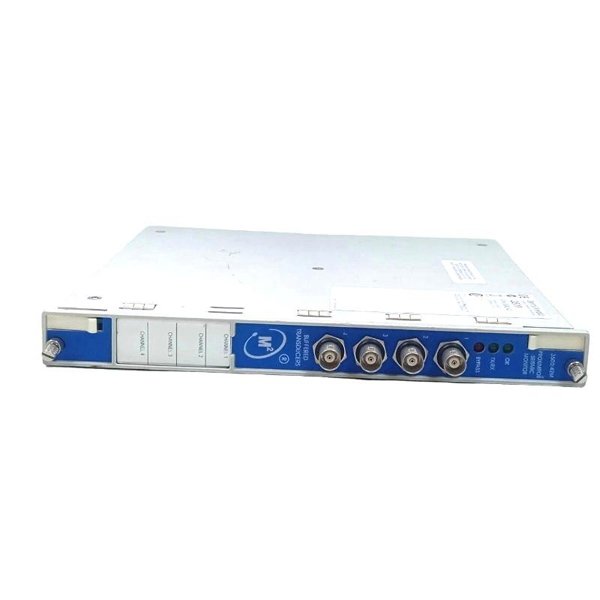

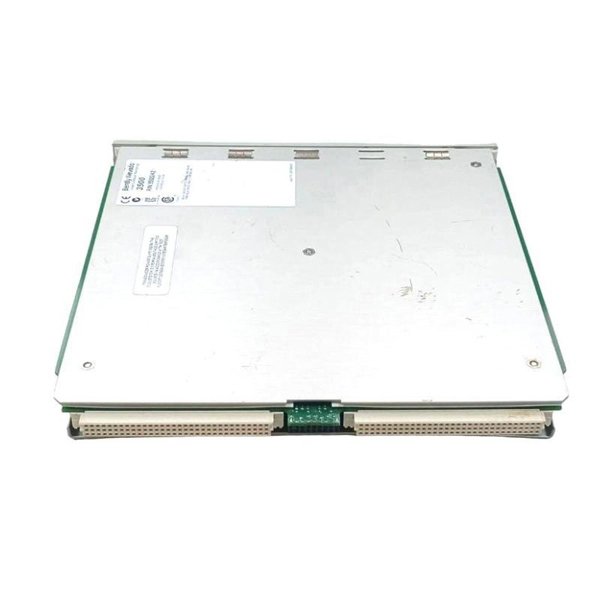

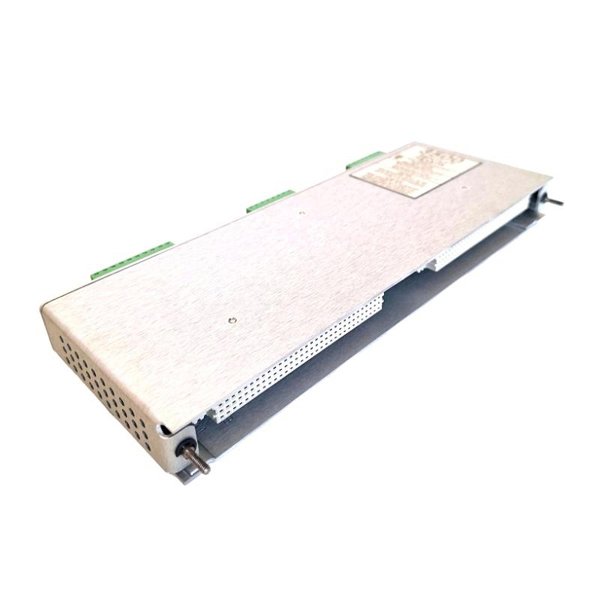

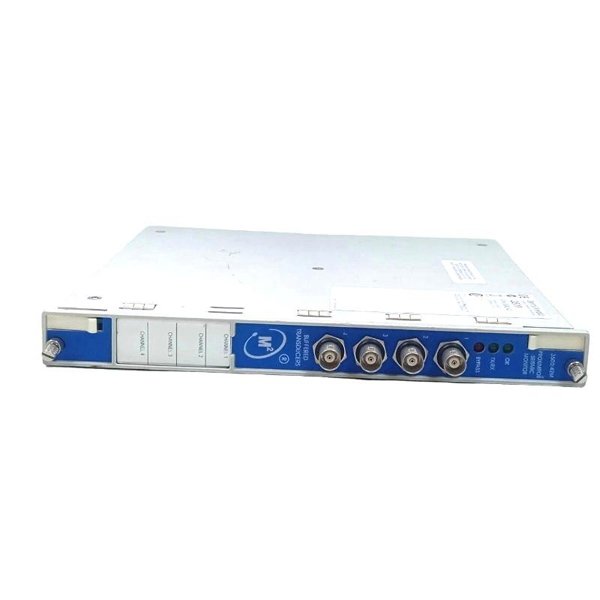

Bently Nevada 3500/42M 140734-02+140471-01 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42M 140734-02+140471-01

Product Type:Proximitor Seismic Monitor

Origin:USA

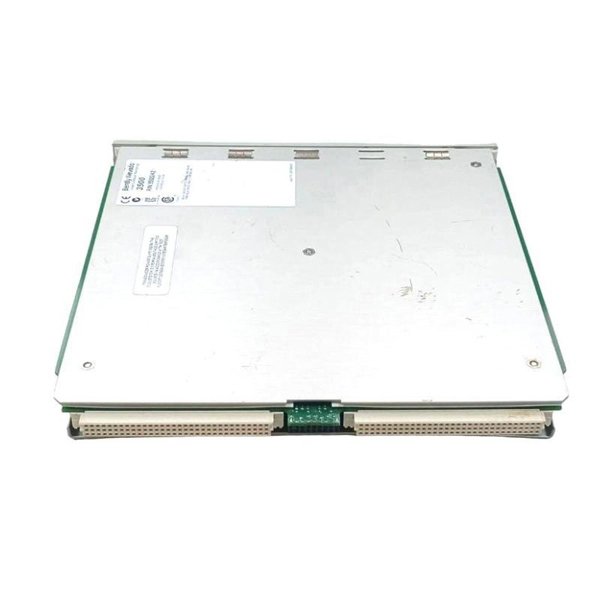

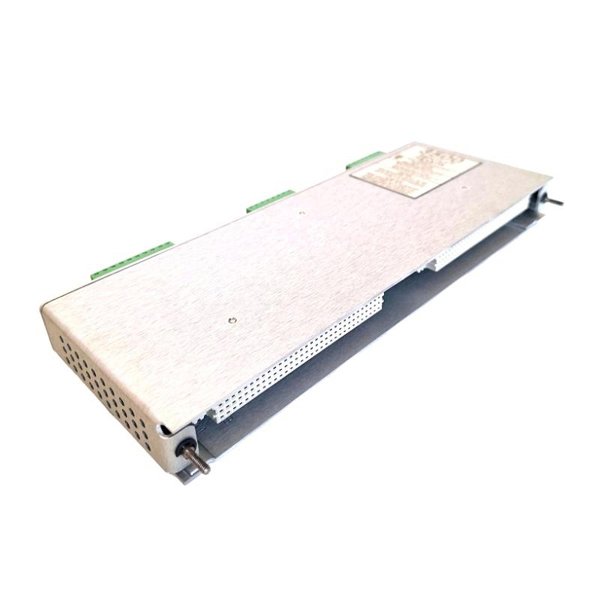

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42M Proximitor Seismic Monitor is a high-performance, four-channel module engineered for continuous condition monitoring and machine protection. It accepts signals from proximity probes and seismic transducers, processes them into precise vibration or position measurements, and compares those with user-configurable alarm thresholds. This model, paired with the 140471-01 Prox/Velom I/O module, ensures comprehensive data capture for radial vibration, thrust position, acceleration, differential expansion, eccentricity, shaft absolute, and more.

Technical Specifications

| Parameter | Description |

|---|---|

| Channels | 4 (programmable in pairs) |

| Input Signal Types | Proximity, velocity, or acceleration transducers |

| Power Consumption | 7.7 W typical |

| Input Impedance | 10 kΩ (Proximitor/acceleration) |

| Transducer Power Supply | -24 Vdc |

| Buffered Output Impedance | 550 Ω |

| Recorder Output | 4–20 mA, 0–600 Ω load |

| Signal Conditioning | Programmable filtering and integration per channel |

| Frequency Response (Acceleration) | 3 Hz – 30,000 Hz |

| Frequency Response (Velocity) | 3 Hz – 5,500 Hz |

| LED Indicators | OK, TX/RX, BYPASS |

| Dimensions (Monitor Module) | 241.3 x 24.4 x 241.8 mm (H x W x D) |

| Weight (Monitor Module) | 0.91 kg |

| Environmental Limits | -30°C to +65°C operating, -40°C to +85°C storage, 95% RH non-condensing |

| Hazardous Location Certification | Class I Div 2, ATEX Zone 2 approvals |

Applications

-

Steam and gas turbines

-

Compressors and expanders

-

Electric motors and gearboxes

-

Industrial fans and pumps

-

Rotating and reciprocating machinery requiring high-precision condition monitoring

-

Machinery requiring dual-channel measurement like shaft absolute, REBAM, or differential expansion

Advantages

-

Simultaneous monitoring of up to four transducers

-

High-resolution dynamic signal analysis with multiple filtering options

-

Comprehensive static value outputs: direct, 1X/2X amplitude and phase, Smax, and more

-

Buffered outputs for external diagnostics and integration

-

Supports proximity probes, Velomitor® velocity sensors, and accelerometers

-

Integrated with Bently Nevada 3500 series machinery protection systems

-

Fast response time (<100 ms), ideal for trip systems

-

Modular design enables easy system expansion and maintenance

FAQs

Q1: What types of sensors can be connected to the 3500/42M monitor?

A1: It supports proximity probes, velocity sensors (Velomitor), and acceleration transducers.

Q2: How are the channels configured?

A2: Channels are configured in pairs, allowing up to two functions simultaneously (e.g., radial vibration and thrust position).

Q3: What is the frequency response range for vibration monitoring?

A3: It ranges from 3 Hz to 30,000 Hz depending on the selected mode and sensor.

Q4: Can I use this module for REBAM analysis?

A4: Yes, REBAM (Rolling Element Bearing Analysis Module) functionality is supported with programmable filter sets.

Q5: How accurate are the alarm setpoints?

A5: Alarm accuracy is within ±0.13% of the desired value.

Q6: Is the unit certified for hazardous environments?

A6: Yes, it is certified for ATEX Zone 2, Class I Div 2 with appropriate I/O modules.

Q7: What is the buffered output impedance?

A7: 550 Ohms for standard buffered transducer outputs.

Q8: What recorder output format is provided?

A8: 4 to 20 mA current output, proportional to the full-scale signal value.

Q9: Does the monitor require specific software?

A9: Yes, it is compatible with 3500/01 software version 2.50 or later and DM2000 version 3.10 or later.

Q10: How is the monitor integrated into the 3500 rack system?

A10: It occupies one full-height front slot and requires a corresponding I/O module in the rear slot.

Bently Nevada 3500/42M 140734-02+140471-01 Proximitor Seismic Monitor

Manufacturer:Bently Nevada

Product Number:3500/42M 140734-02+140471-01

Product Type:Proximitor Seismic Monitor

Origin:USA

Dimensions:241.3 x 24.4 x 241.8 mm

Weight:0.91 kg

Views:41

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 3500/42M Proximitor Seismic Monitor is a high-performance, four-channel module engineered for continuous condition monitoring and machine protection. It accepts signals from proximity probes and seismic transducers, processes them into precise vibration or position measurements, and compares those with user-configurable alarm thresholds. This model, paired with the 140471-01 Prox/Velom I/O module, ensures comprehensive data capture for radial vibration, thrust position, acceleration, differential expansion, eccentricity, shaft absolute, and more.

Technical Specifications

| Parameter | Description |

|---|---|

| Channels | 4 (programmable in pairs) |

| Input Signal Types | Proximity, velocity, or acceleration transducers |

| Power Consumption | 7.7 W typical |

| Input Impedance | 10 kΩ (Proximitor/acceleration) |

| Transducer Power Supply | -24 Vdc |

| Buffered Output Impedance | 550 Ω |

| Recorder Output | 4–20 mA, 0–600 Ω load |

| Signal Conditioning | Programmable filtering and integration per channel |

| Frequency Response (Acceleration) | 3 Hz – 30,000 Hz |

| Frequency Response (Velocity) | 3 Hz – 5,500 Hz |

| LED Indicators | OK, TX/RX, BYPASS |

| Dimensions (Monitor Module) | 241.3 x 24.4 x 241.8 mm (H x W x D) |

| Weight (Monitor Module) | 0.91 kg |

| Environmental Limits | -30°C to +65°C operating, -40°C to +85°C storage, 95% RH non-condensing |

| Hazardous Location Certification | Class I Div 2, ATEX Zone 2 approvals |

Applications

-

Steam and gas turbines

-

Compressors and expanders

-

Electric motors and gearboxes

-

Industrial fans and pumps

-

Rotating and reciprocating machinery requiring high-precision condition monitoring

-

Machinery requiring dual-channel measurement like shaft absolute, REBAM, or differential expansion

Advantages

-

Simultaneous monitoring of up to four transducers

-

High-resolution dynamic signal analysis with multiple filtering options

-

Comprehensive static value outputs: direct, 1X/2X amplitude and phase, Smax, and more

-

Buffered outputs for external diagnostics and integration

-

Supports proximity probes, Velomitor® velocity sensors, and accelerometers

-

Integrated with Bently Nevada 3500 series machinery protection systems

-

Fast response time (<100 ms), ideal for trip systems

-

Modular design enables easy system expansion and maintenance

FAQs

Q1: What types of sensors can be connected to the 3500/42M monitor?

A1: It supports proximity probes, velocity sensors (Velomitor), and acceleration transducers.

Q2: How are the channels configured?

A2: Channels are configured in pairs, allowing up to two functions simultaneously (e.g., radial vibration and thrust position).

Q3: What is the frequency response range for vibration monitoring?

A3: It ranges from 3 Hz to 30,000 Hz depending on the selected mode and sensor.

Q4: Can I use this module for REBAM analysis?

A4: Yes, REBAM (Rolling Element Bearing Analysis Module) functionality is supported with programmable filter sets.

Q5: How accurate are the alarm setpoints?

A5: Alarm accuracy is within ±0.13% of the desired value.

Q6: Is the unit certified for hazardous environments?

A6: Yes, it is certified for ATEX Zone 2, Class I Div 2 with appropriate I/O modules.

Q7: What is the buffered output impedance?

A7: 550 Ohms for standard buffered transducer outputs.

Q8: What recorder output format is provided?

A8: 4 to 20 mA current output, proportional to the full-scale signal value.

Q9: Does the monitor require specific software?

A9: Yes, it is compatible with 3500/01 software version 2.50 or later and DM2000 version 3.10 or later.

Q10: How is the monitor integrated into the 3500 rack system?

A10: It occupies one full-height front slot and requires a corresponding I/O module in the rear slot.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...