Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

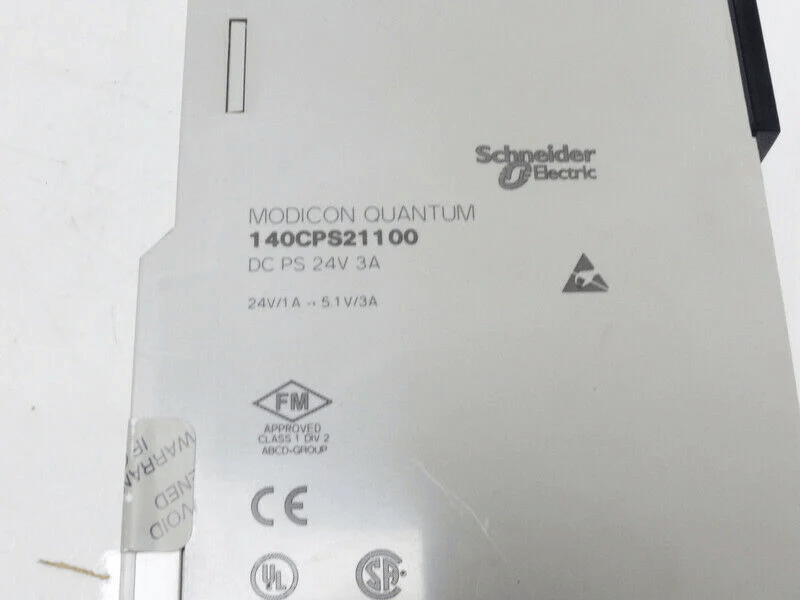

Schneider ATV71HU75Y Variable Speed Drive

Manufacturer:Schneider

Product Number:ATV71HU75Y

Product Type:Variable Speed Drive

Origin:France

Dimensions:420 x 236 x 240 mm

Weight:30 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric ATV71HU75Y is a high-performance Variable Speed Drive (VSD) engineered for demanding industrial motor control applications. It belongs to the widely respected Altivar 71 series, a premium line of drives designed for complex, high-power variable torque and constant torque tasks.

The ATV71HU75Y is rated at 7.5 kW (10 HP) and is designed for 200–240V three-phase input, making it an excellent choice for low-voltage industrial environments. It supports multiple control modes—including sensorless vector control, flux vector control with feedback, and voltage/frequency (V/F) ratio control—providing exceptional performance across a wide range of motor types and applications.

Equipped with integrated communication protocols (Modbus and CANopen), Safe Torque Off (STO) safety function, and optional expandability for Ethernet/IP, Profibus, and DeviceNet, the ATV71HU75Y combines advanced functionality with rugged durability and energy efficiency.

Product Specifications

| Parameter | Details |

|---|---|

| Model | ATV71HU75Y |

| Brand | Schneider Electric |

| Series | Altivar 71 |

| Motor Power Rating | 7.5 kW (10 HP) |

| Input Voltage | 200–240 V AC, three-phase |

| Input Frequency | 50/60 Hz |

| Output Voltage | 0 to supply voltage |

| Output Frequency | 0.1 to 599 Hz |

| Rated Output Current | 31 A |

| Control Modes | V/F, Sensorless Vector Control, Flux Vector with Feedback |

| Compatible Motors | Asynchronous and synchronous |

| Communication Protocols | Integrated Modbus, CANopen |

| Optional Communication | Ethernet/IP, Profibus DP, DeviceNet (via expansion cards) |

| Digital Inputs | 7 programmable |

| Analog Inputs | 3 (one for PT100) |

| Analog Outputs | 2 |

| Relay Outputs | 2 |

| Integrated Safety | Safe Torque Off (STO) |

| Cooling Method | Forced air cooling |

| Enclosure Rating | IP20 (standard), IP21 with option kit |

| Mounting Options | Wall or panel mount |

| Operating Temperature | -10°C to +50°C (no derating) |

| Certifications | CE, UL, CSA, RoHS, IEC 61800-5-1 |

| Dimensions (H × W × D) | 420 x 236 x 240 mm |

| Weight | 30 kg |

Product Applications

The ATV71HU75Y is built for precision control and high adaptability, making it ideal for:

-

Cranes and Hoists

Delivers smooth start/stop and torque management for heavy lifting systems.

-

Packaging Machinery

Supports high-speed and dynamic control required in automated packaging lines.

-

HVAC Systems

Built-in PID regulator enables optimized energy usage in ventilation, cooling, and heating systems.

-

Mixers and Agitators

Offers torque accuracy and speed consistency for mixing applications in food and chemical industries.

-

Conveyor Systems

Smooth ramp-up/ramp-down control improves mechanical life and throughput in material handling.

-

Textile Equipment

Provides synchronized control in weaving, dyeing, and spinning operations.

Product Advantages

-

Advanced Motor Control

Supports synchronous and asynchronous motors with advanced control algorithms for improved accuracy and stability.

-

Robust Design for Harsh Environments

Reliable performance in a wide range of temperatures and dusty or humid industrial conditions.

-

Modular Communication Flexibility

Allows fieldbus and Ethernet expansion, integrating seamlessly into various automation architectures.

-

Integrated Safety Functions

The built-in STO function meets SIL3 requirements, enhancing operator and equipment safety.

-

Energy Efficiency Optimization

Features motor flux optimization, low standby losses, and PID regulation to minimize energy waste.

-

Easy Setup and Maintenance

With SoMove configuration software, troubleshooting and parameter tuning are intuitive and fast.

-

Adaptable I/O Configuration

Digital and analog inputs/outputs are fully programmable to match diverse control schemes.

Frequently Asked Questions (FAQ)

-

What power rating is the ATV71HU75Y designed for?

This drive is rated for 7.5 kW (10 HP) applications.

-

What is the supported input voltage?

The drive operates on 200–240V three-phase AC power.

-

Does it support safety functions?

Yes, it includes Safe Torque Off (STO) for enhanced protection.

-

Is the drive compatible with synchronous motors?

Absolutely, it supports both synchronous and asynchronous motors.

-

What control methods are available?

V/F control, sensorless vector control, and vector control with feedback.

-

Can this drive be connected to Ethernet/IP networks?

Yes, using optional communication cards, Ethernet/IP and others are supported.

-

Is this drive suitable for HVAC applications?

Yes, especially with its integrated PID control and energy-saving features.

-

What software is used for configuration?

Schneider’s SoMove software allows easy parameter setting and monitoring.

-

What is the enclosure rating?

Standard is IP20, but can be upgraded to IP21 with accessories.

-

How much does the ATV71HU75Y weigh?

The unit weighs 30 kg.

Schneider ATV71HU75Y Variable Speed Drive

Manufacturer:Schneider

Product Number:ATV71HU75Y

Product Type:Variable Speed Drive

Origin:France

Dimensions:420 x 236 x 240 mm

Weight:30 kg

Views:32

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Schneider Electric ATV71HU75Y is a high-performance Variable Speed Drive (VSD) engineered for demanding industrial motor control applications. It belongs to the widely respected Altivar 71 series, a premium line of drives designed for complex, high-power variable torque and constant torque tasks.

The ATV71HU75Y is rated at 7.5 kW (10 HP) and is designed for 200–240V three-phase input, making it an excellent choice for low-voltage industrial environments. It supports multiple control modes—including sensorless vector control, flux vector control with feedback, and voltage/frequency (V/F) ratio control—providing exceptional performance across a wide range of motor types and applications.

Equipped with integrated communication protocols (Modbus and CANopen), Safe Torque Off (STO) safety function, and optional expandability for Ethernet/IP, Profibus, and DeviceNet, the ATV71HU75Y combines advanced functionality with rugged durability and energy efficiency.

Product Specifications

| Parameter | Details |

|---|---|

| Model | ATV71HU75Y |

| Brand | Schneider Electric |

| Series | Altivar 71 |

| Motor Power Rating | 7.5 kW (10 HP) |

| Input Voltage | 200–240 V AC, three-phase |

| Input Frequency | 50/60 Hz |

| Output Voltage | 0 to supply voltage |

| Output Frequency | 0.1 to 599 Hz |

| Rated Output Current | 31 A |

| Control Modes | V/F, Sensorless Vector Control, Flux Vector with Feedback |

| Compatible Motors | Asynchronous and synchronous |

| Communication Protocols | Integrated Modbus, CANopen |

| Optional Communication | Ethernet/IP, Profibus DP, DeviceNet (via expansion cards) |

| Digital Inputs | 7 programmable |

| Analog Inputs | 3 (one for PT100) |

| Analog Outputs | 2 |

| Relay Outputs | 2 |

| Integrated Safety | Safe Torque Off (STO) |

| Cooling Method | Forced air cooling |

| Enclosure Rating | IP20 (standard), IP21 with option kit |

| Mounting Options | Wall or panel mount |

| Operating Temperature | -10°C to +50°C (no derating) |

| Certifications | CE, UL, CSA, RoHS, IEC 61800-5-1 |

| Dimensions (H × W × D) | 420 x 236 x 240 mm |

| Weight | 30 kg |

Product Applications

The ATV71HU75Y is built for precision control and high adaptability, making it ideal for:

-

Cranes and Hoists

Delivers smooth start/stop and torque management for heavy lifting systems.

-

Packaging Machinery

Supports high-speed and dynamic control required in automated packaging lines.

-

HVAC Systems

Built-in PID regulator enables optimized energy usage in ventilation, cooling, and heating systems.

-

Mixers and Agitators

Offers torque accuracy and speed consistency for mixing applications in food and chemical industries.

-

Conveyor Systems

Smooth ramp-up/ramp-down control improves mechanical life and throughput in material handling.

-

Textile Equipment

Provides synchronized control in weaving, dyeing, and spinning operations.

Product Advantages

-

Advanced Motor Control

Supports synchronous and asynchronous motors with advanced control algorithms for improved accuracy and stability.

-

Robust Design for Harsh Environments

Reliable performance in a wide range of temperatures and dusty or humid industrial conditions.

-

Modular Communication Flexibility

Allows fieldbus and Ethernet expansion, integrating seamlessly into various automation architectures.

-

Integrated Safety Functions

The built-in STO function meets SIL3 requirements, enhancing operator and equipment safety.

-

Energy Efficiency Optimization

Features motor flux optimization, low standby losses, and PID regulation to minimize energy waste.

-

Easy Setup and Maintenance

With SoMove configuration software, troubleshooting and parameter tuning are intuitive and fast.

-

Adaptable I/O Configuration

Digital and analog inputs/outputs are fully programmable to match diverse control schemes.

Frequently Asked Questions (FAQ)

-

What power rating is the ATV71HU75Y designed for?

This drive is rated for 7.5 kW (10 HP) applications.

-

What is the supported input voltage?

The drive operates on 200–240V three-phase AC power.

-

Does it support safety functions?

Yes, it includes Safe Torque Off (STO) for enhanced protection.

-

Is the drive compatible with synchronous motors?

Absolutely, it supports both synchronous and asynchronous motors.

-

What control methods are available?

V/F control, sensorless vector control, and vector control with feedback.

-

Can this drive be connected to Ethernet/IP networks?

Yes, using optional communication cards, Ethernet/IP and others are supported.

-

Is this drive suitable for HVAC applications?

Yes, especially with its integrated PID control and energy-saving features.

-

What software is used for configuration?

Schneider’s SoMove software allows easy parameter setting and monitoring.

-

What is the enclosure rating?

Standard is IP20, but can be upgraded to IP21 with accessories.

-

How much does the ATV71HU75Y weigh?

The unit weighs 30 kg.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...