Our Products

Comprehensive industrial automation solutions for global industries

Contact us

If you are interested in our products and want to know more details,please Contact us,we will reply you as soon as we can.

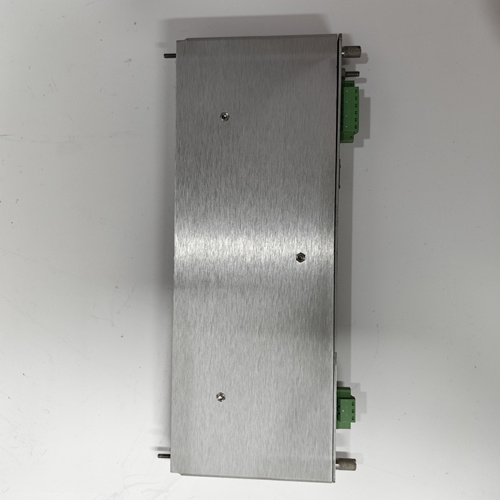

Bently Nevada 330103-00-18-10-02-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-00-18-10-02-00

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1.0 meter

Weight:0.323 kg

Views:21

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-18-10-02-00 is part of the 3300 XL 8 mm Proximity Probe system, designed for precise non-contact measurement of shaft vibration and position in rotating machinery. It provides accurate data required for machinery protection and condition monitoring systems, fully compliant with API 670 standards.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330103-00-18-10-02-00 |

| Probe Type | 3300 XL 8 mm Proximity Probe (eddy-current) |

| Unthreaded Length | 0 mm |

| Case Length | 180 mm |

| Total Cable Length | 1.0 meter |

| Connector Type | Miniature coaxial ClickLoc™ connector |

| Cable Type | Standard cable |

| Agency Approval | Not required |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Compliance | API 670, 4th Edition |

| Durability Features | TipLoc™ molding, CableLoc™ attachment, optional FluidLoc® sealing |

Applications

The 3300 XL 8 mm probe is engineered for a wide range of industrial applications:

-

Vibration Monitoring: Measures shaft dynamic motion in turbines, compressors, and pumps.

-

Position Measurement: Detects shaft axial and radial position for accurate machine alignment.

-

Keyphasor®/Speed Sensing: Provides reliable reference signals for phase and speed measurements.

-

Machinery Protection: Integral component of Bently Nevada protection systems to prevent critical failures.

-

Fluid-Film Bearing Machines: Specifically designed for turbines, motors, and other rotating machines using fluid-film bearings.

Advantages

-

High Accuracy: Provides consistent and linear response across a wide measurement range.

-

Robust Design: TipLoc™ probe encapsulation and CableLoc™ strain relief ensure long-term durability.

-

Easy Connectivity: ClickLoc™ connectors provide secure, corrosion-resistant, and tool-free connections.

-

Environmental Resistance: Optional FluidLoc® variant prevents fluid ingress for harsh industrial settings.

-

System Compatibility: Fully interchangeable with other Bently Nevada 5 mm and 8 mm probes and extension cables without calibration.

-

API Compliance: Meets industry standards for safety, reliability, and performance.

Frequently Asked Questions (FAQ)

Q1: What is the main function of the 330103-00-18-10-02-00 probe?

A1: It measures shaft vibration and position in rotating machinery using eddy-current technology.

Q2: Can this probe be used for Keyphasor® applications?

A2: Yes, it supports Keyphasor® reference and speed measurements.

Q3: Does it meet API 670 requirements?

A3: Yes, the 3300 XL 8 mm system is fully compliant with API 670 (4th edition).

Q4: What is the durability feature of this probe?

A4: It incorporates TipLoc™ molding and CableLoc™ attachment to withstand mechanical stress and pull forces up to 330 N.

Q5: Is the probe compatible with older Bently Nevada 3300 series?

A5: Yes, it is backward compatible and interchangeable with earlier systems.

Q6: What is the typical installation length of the probe?

A6: This model features a 180 mm case length with a 1.0 m cable.

Q7: How does the probe resist environmental factors?

A7: It uses gold-plated ClickLoc™ connectors and an optional FluidLoc® sealing system.

Q8: What is the total weight of the probe?

A8: The probe weighs 0.323 kg.

Q9: Can it be used in high-temperature environments?

A9: Yes, it is designed for industrial machinery operating under wide temperature ranges.

Q10: What makes the 3300 XL system superior to older probe designs?

A10: It offers improved linearity, temperature stability, and enhanced mechanical robustness compared to legacy systems.

Bently Nevada 330103-00-18-10-02-00 3300 XL 8 mm Proximity Probe

Manufacturer:Bently Nevada

Product Number:330103-00-18-10-02-00

Product Type:3300 XL 8 mm Proximity Probe

Origin:USA

Total Length:1.0 meter

Weight:0.323 kg

Views:21

Payment Methods:T/T, PayPal, Western Union

Condition:New & In Stock

Warranty:1 Year

Lead Time:1-3 Working Days

Certificate:COO

Courier partners:DHL, UPS, TNT, FedEx and EMS.

Business hours:7*24

Product Description

The Bently Nevada 330103-00-18-10-02-00 is part of the 3300 XL 8 mm Proximity Probe system, designed for precise non-contact measurement of shaft vibration and position in rotating machinery. It provides accurate data required for machinery protection and condition monitoring systems, fully compliant with API 670 standards.

Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | 330103-00-18-10-02-00 |

| Probe Type | 3300 XL 8 mm Proximity Probe (eddy-current) |

| Unthreaded Length | 0 mm |

| Case Length | 180 mm |

| Total Cable Length | 1.0 meter |

| Connector Type | Miniature coaxial ClickLoc™ connector |

| Cable Type | Standard cable |

| Agency Approval | Not required |

| Total Length | 1.0 meter |

| Weight | 0.323 kg |

| Compliance | API 670, 4th Edition |

| Durability Features | TipLoc™ molding, CableLoc™ attachment, optional FluidLoc® sealing |

Applications

The 3300 XL 8 mm probe is engineered for a wide range of industrial applications:

-

Vibration Monitoring: Measures shaft dynamic motion in turbines, compressors, and pumps.

-

Position Measurement: Detects shaft axial and radial position for accurate machine alignment.

-

Keyphasor®/Speed Sensing: Provides reliable reference signals for phase and speed measurements.

-

Machinery Protection: Integral component of Bently Nevada protection systems to prevent critical failures.

-

Fluid-Film Bearing Machines: Specifically designed for turbines, motors, and other rotating machines using fluid-film bearings.

Advantages

-

High Accuracy: Provides consistent and linear response across a wide measurement range.

-

Robust Design: TipLoc™ probe encapsulation and CableLoc™ strain relief ensure long-term durability.

-

Easy Connectivity: ClickLoc™ connectors provide secure, corrosion-resistant, and tool-free connections.

-

Environmental Resistance: Optional FluidLoc® variant prevents fluid ingress for harsh industrial settings.

-

System Compatibility: Fully interchangeable with other Bently Nevada 5 mm and 8 mm probes and extension cables without calibration.

-

API Compliance: Meets industry standards for safety, reliability, and performance.

Frequently Asked Questions (FAQ)

Q1: What is the main function of the 330103-00-18-10-02-00 probe?

A1: It measures shaft vibration and position in rotating machinery using eddy-current technology.

Q2: Can this probe be used for Keyphasor® applications?

A2: Yes, it supports Keyphasor® reference and speed measurements.

Q3: Does it meet API 670 requirements?

A3: Yes, the 3300 XL 8 mm system is fully compliant with API 670 (4th edition).

Q4: What is the durability feature of this probe?

A4: It incorporates TipLoc™ molding and CableLoc™ attachment to withstand mechanical stress and pull forces up to 330 N.

Q5: Is the probe compatible with older Bently Nevada 3300 series?

A5: Yes, it is backward compatible and interchangeable with earlier systems.

Q6: What is the typical installation length of the probe?

A6: This model features a 180 mm case length with a 1.0 m cable.

Q7: How does the probe resist environmental factors?

A7: It uses gold-plated ClickLoc™ connectors and an optional FluidLoc® sealing system.

Q8: What is the total weight of the probe?

A8: The probe weighs 0.323 kg.

Q9: Can it be used in high-temperature environments?

A9: Yes, it is designed for industrial machinery operating under wide temperature ranges.

Q10: What makes the 3300 XL system superior to older probe designs?

A10: It offers improved linearity, temperature stability, and enhanced mechanical robustness compared to legacy systems.

Need a Custom Automation Solution?

Our team of experts can design and implement a tailored automation system to meet your specific requirements.

Loading comments...

Loading comments...